In practice, safety precautions for Potassium Bromide (KBr) extend beyond personal protection to encompass meticulous procedural steps that ensure the quality and accuracy of your analytical results. While KBr is a low-hazard material, improper handling will compromise your experiment, primarily by introducing moisture which obscures data and degrades the pellet. The key is to treat KBr not just as a chemical, but as a high-purity optical material.

The most critical "safety precaution" when working with KBr for spectroscopy is the rigorous exclusion of water. Moisture is the primary cause of both physical pellet failure and inaccurate spectral data, making its removal the central goal of your preparation technique.

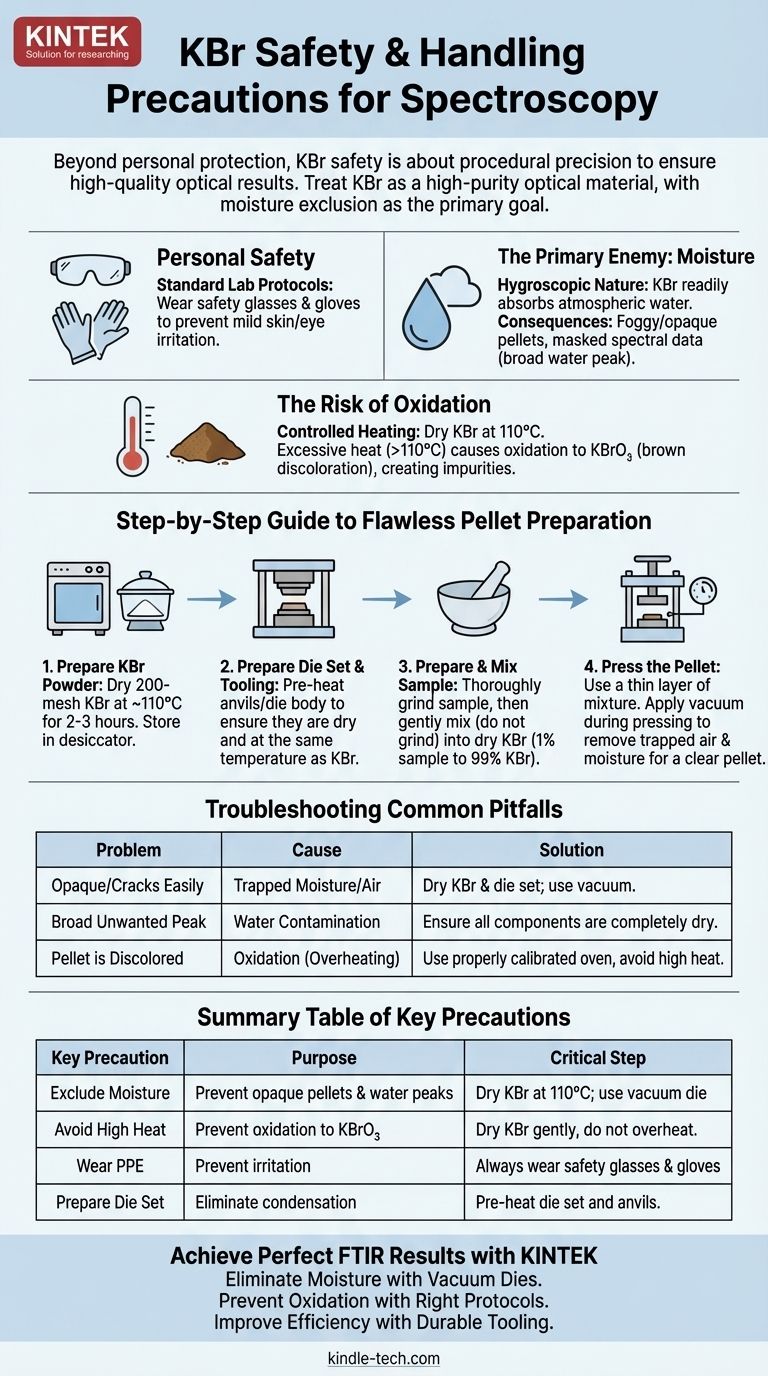

Foundational Principles of KBr Handling

To use KBr effectively, you must understand its primary vulnerabilities: moisture and high heat. Every precaution is designed to mitigate one of these two factors.

Standard Personal Safety

While KBr has low toxicity, it is a salt that can act as a mild skin and eye irritant. Always follow standard laboratory safety protocols. Wear safety glasses and gloves when handling the powder to prevent contact and potential irritation.

The Primary Enemy: Moisture

Water is the main adversary in KBr pellet preparation. KBr is hygroscopic, meaning it readily absorbs moisture from the atmosphere.

This moisture causes two major problems. First, it can dissolve the KBr, causing pressed pellets to appear foggy or opaque instead of clear. Second, water has a very strong, broad absorption band in the infrared spectrum, which can easily mask the signals from your actual sample.

The Risk of Oxidation

When drying KBr powder, you must use controlled heat. Rapid or excessive heating (well above the recommended 110 °C) can cause the potassium bromide (KBr) to oxidize into potassium bromate (KBrO₃).

This oxidation is often visible as a brown discoloration in the powder. The formation of KBrO₃ introduces an impurity that can create unwanted artifacts in your final spectrum.

A Step-by-Step Guide to Flawless Pellet Preparation

Achieving a transparent, high-quality pellet requires a systematic approach. Each step is designed to prevent the introduction of moisture or other contaminants.

Step 1: Prepare the KBr Powder

The KBr itself must be exceptionally dry and finely ground. The standard is to use KBr powder pulverized to a 200-mesh particle size.

Before use, dry the KBr powder in an oven at approximately 110 °C for two to three hours. Store the dried powder in a desiccator to prevent it from reabsorbing atmospheric moisture.

Step 2: Prepare the Die Set and Tooling

Your pellet press die set is a major potential source of moisture. To eliminate this, gently heat the anvils and the die set body before use to ensure they are completely dry.

Make sure the anvils, die set, and your KBr powder are all at the same temperature before pressing the pellet to avoid condensation.

Step 3: Prepare and Mix the Sample

It is the sample, not the KBr powder, that should be thoroughly ground into a fine powder. Grinding KBr powder excessively can increase its surface area, promoting moisture absorption.

Mix your finely ground sample into the dry KBr powder. The goal is a homogenous mixture, typically at a concentration of about 1% sample to 99% KBr. Do not grind the two together; simply mix them gently.

Step 4: Press the Pellet

Use just enough of the KBr/sample mixture to create a thin, even layer on the anvil face. Using too much powder can trap air and lead to a poor-quality pellet.

If using a vacuum die, ensure it is properly assembled with good seals. Applying a vacuum during pressing is critical for removing trapped air and residual moisture, which prevents light scattering and ensures the pellet is transparent and mechanically strong.

Common Pitfalls and How to Avoid Them

Even with careful preparation, problems can arise. Understanding the cause of common failures helps you troubleshoot effectively.

Problem: The Pellet is Opaque or Cracks Easily

This is almost always caused by trapped moisture or air. The solution is to ensure your KBr and die set are perfectly dry and to maintain an adequate vacuum during the pressing process. Insufficient pressure can also be a cause.

Problem: The Spectrum Has a Broad, Unwanted Peak

A large, broad absorption band in the 3400 cm⁻¹ region and a sharper one near 1630 cm⁻¹ are classic signs of water contamination. This confirms that moisture was present in your KBr, sample, or on the die set.

Problem: The Pellet is Discolored

A yellow or brown tint in the KBr pellet indicates that the KBr was overheated during the drying step, causing oxidation to KBrO₃. Use a properly calibrated oven and avoid rapid, high-temperature heating.

How to Apply This to Your Project

Your specific focus will determine which precautions are most critical for you.

- If your primary focus is data accuracy: Your top priority is rigorously drying the KBr powder and running a background scan with a pure KBr pellet to digitally subtract any remaining moisture signals.

- If your primary focus is efficiency and throughput: Pre-heating your die set and using a vacuum die are the most important steps to prevent pellet failure and avoid the need to remake samples.

- If your primary focus is personal safety: The key is simple but non-negotiable—always wear gloves and safety glasses when handling the powder.

Ultimately, mastering the KBr technique is a matter of controlling the environment, with a relentless focus on eliminating moisture.

Summary Table:

| Key Precaution | Purpose | Critical Step |

|---|---|---|

| Exclude Moisture | Prevent opaque pellets & water peaks in spectrum | Dry KBr at 110°C; use vacuum die |

| Avoid High Heat | Prevent oxidation to KBrO₃ (brown discoloration) | Dry KBr gently, do not overheat |

| Wear PPE | Prevent skin/eye irritation from powder | Always wear safety glasses and gloves |

| Prepare Die Set | Eliminate condensation and moisture source | Pre-heat die set and anvils before use |

Achieve Perfect FTIR Results Every Time

Struggling with opaque pellets or water peaks in your spectra? The key to flawless KBr pellet preparation is precision equipment and expert technique. KINTEK specializes in high-quality laboratory equipment and consumables, including reliable pellet presses and vacuum dies designed specifically for moisture-sensitive FTIR sample preparation.

Our products help you:

- Eliminate Moisture: Vacuum dies ensure trapped air and water are removed for crystal-clear pellets.

- Prevent Oxidation: Trust our expertise to recommend the right drying protocols.

- Improve Efficiency: Streamline your workflow with durable, easy-to-use tooling.

Ready to enhance your lab's accuracy and efficiency? Contact our experts today to find the perfect solution for your spectroscopy needs!

Visual Guide

Related Products

- kbr pellet press 2t

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- Why KBr is used for IR spectroscopy? The Ideal Medium for Solid Sample Analysis

- How much sample is needed for IR? Optimize Your Analysis with Minimal Material

- What is KBr disc method in IR spectroscopy? A Guide to Solid Sample Analysis

- How do you prepare samples for infrared spectroscopy? Master Solid, Liquid & Gas Techniques

- How do you prepare a KBr pellet for IR spectroscopy? Master the Key Steps for a Clear Spectrum