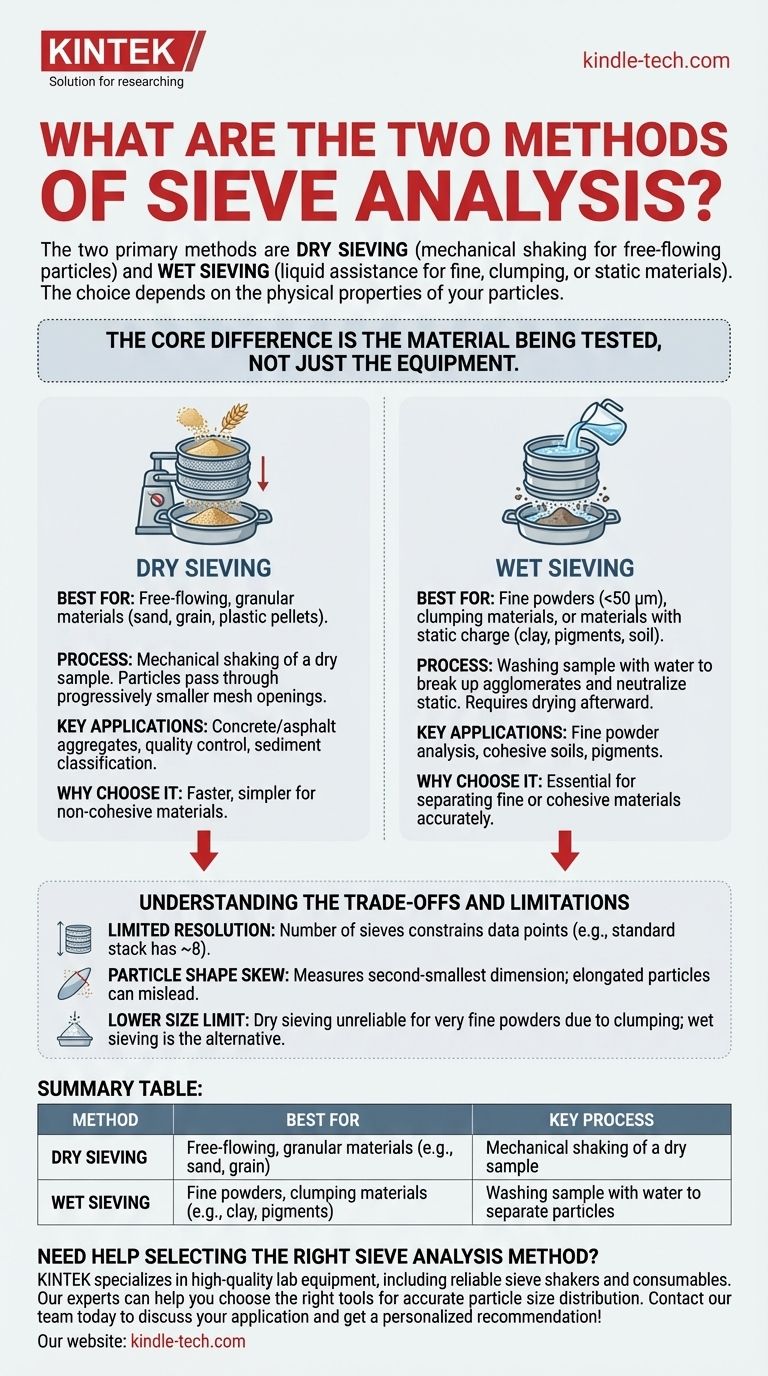

The two primary methods of sieve analysis are dry sieving and wet sieving. Dry sieving is the most common approach, using mechanical shaking to separate dry, free-flowing particles, while wet sieving uses a liquid (typically water) to help separate materials that are very fine, tend to clump together, or hold a static charge.

The core difference isn't the equipment but the material being tested. Your choice between dry and wet sieving depends entirely on the physical properties of your particles and whether they can pass through the sieve mesh freely without assistance from a liquid.

The Purpose of Sieve Analysis

Sieve analysis is a long-established and trusted method for determining the particle size distribution of a granular material. It is a cornerstone of quality control in many industries.

Why It's Used

The goal is to sort a sample of material into different size ranges, known as fractions. The weight of each fraction is then measured to calculate the proportion of particles in each size range.

Key Applications

This data is critical for ensuring material consistency and suitability. It's widely used in civil engineering for selecting aggregates for concrete and asphalt, in manufacturing for quality control, and in geology for classifying sediments.

The Two Core Methods Explained

While the principle of passing particles through a mesh is the same, the method of agitation and sample preparation separates the two techniques.

Dry Sieve Analysis

This is the default and most straightforward method. It is suitable for any material composed of particles that do not stick together and can flow freely when agitated.

The process involves placing a dried sample into the top of a stack of sieves with progressively smaller mesh openings. A mechanical sieve shaker then vibrates or taps the stack, causing the particles to work their way down until they are retained by a sieve with a mesh smaller than their diameter.

Wet Sieve Analysis

This method is required when particles are too fine (typically below 50 µm), tend to agglomerate due to moisture, or hold static electricity that causes them to cling to the sieve mesh.

In wet sieving, the sample is placed in the top sieve, and a gentle stream of water is used to wash the finer particles through the stack. This liquid action breaks up clumps and neutralizes static charges, allowing for an accurate separation that would be impossible with dry shaking alone. After sieving, each fraction must be dried before it can be weighed.

Understanding the Trade-offs and Limitations

While sieve analysis is valued for its simplicity, low cost, and reproducibility, it's essential to recognize its limitations to ensure your results are valid.

Resolution is Limited

The detail of your particle size distribution is constrained by the number of sieves you can use. A standard stack may have only 8 sieves, meaning your entire analysis is based on a small number of data points.

Particle Shape Can Skew Results

Sieve analysis measures the second-smallest dimension of a particle—the one that determines if it can pass through a square mesh. Elongated or irregular particles can produce misleading results compared to methods that analyze the true shape, like image processing.

The Lower Size Limit

Dry sieving becomes unreliable for very fine powders, as intermolecular forces can cause significant clumping and screen blockage. This is the primary reason wet sieving exists as an alternative for these challenging materials.

Making the Right Choice for Your Material

Selecting the correct method is the most critical step for achieving an accurate particle size distribution.

- If your material is free-flowing and granular (like sand, grain, or plastic pellets): Dry sieve analysis is the faster, simpler, and appropriate choice.

- If your material is a fine powder, clay, or prone to clumping (like pigments or soil): Wet sieve analysis is necessary to break up agglomerates and ensure particles separate correctly.

Ultimately, choosing the right sieving method ensures the data you collect is a true and reliable reflection of your material's properties.

Summary Table:

| Method | Best For | Key Process |

|---|---|---|

| Dry Sieving | Free-flowing, granular materials (e.g., sand, grain) | Mechanical shaking of a dry sample |

| Wet Sieving | Fine powders, clumping materials (e.g., clay, pigments) | Washing sample with water to separate particles |

Need help selecting the right sieve analysis method for your materials?

KINTEK specializes in high-quality lab equipment, including reliable sieve shakers and consumables for both dry and wet analysis. Our experts can help you choose the right tools to ensure accurate particle size distribution data for your quality control needs.

Contact our team today to discuss your application and get a personalized recommendation!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment

- What function does a sieving system perform during HPS powder pretreatment? Ensure Uniform Particle Size Distribution

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- Why is a precision vibratory sieving system important for Pt/Pd alloy analysis? Ensure Data Integrity & XRD Accuracy

- What is the significance of using a fine sieving system for catalyst particles? Optimize Size for Maximum Reactivity