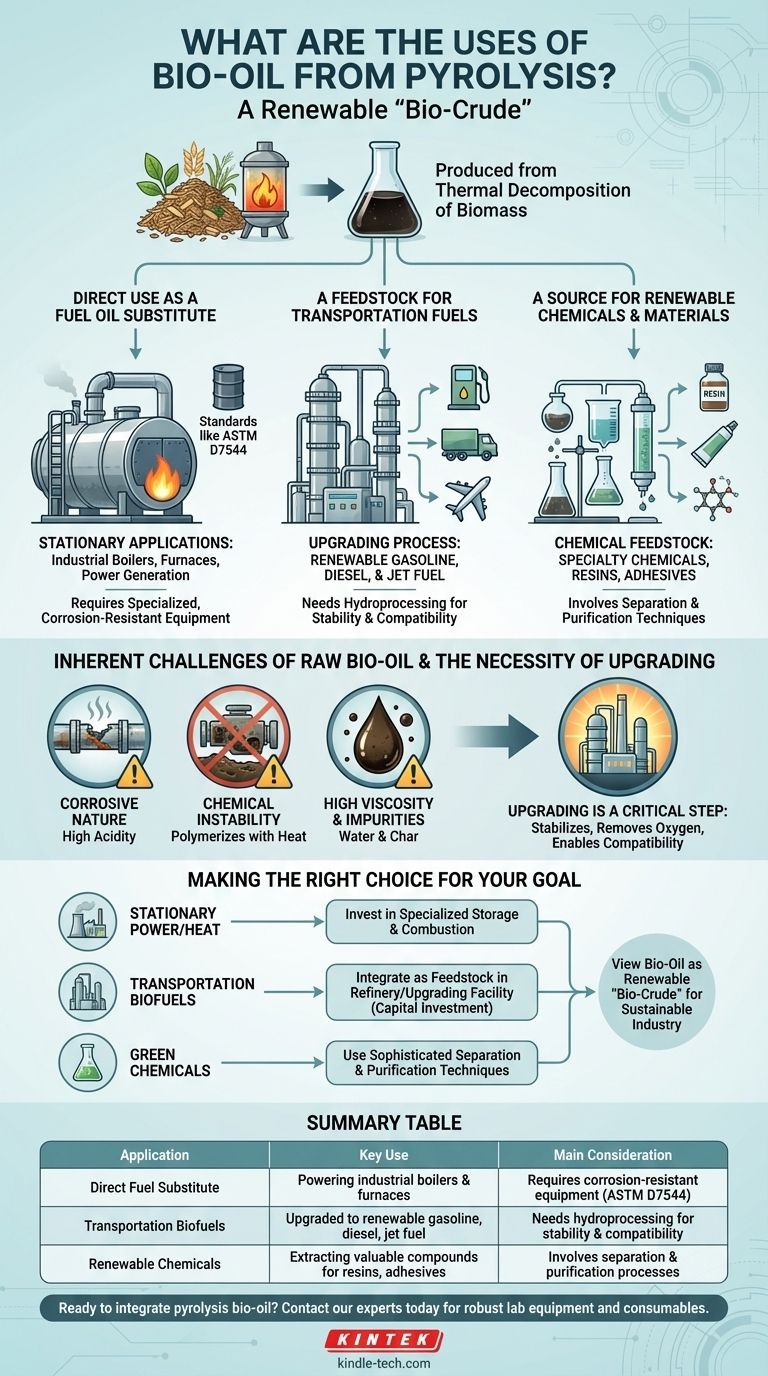

At its core, bio-oil from pyrolysis is a versatile liquid produced from the thermal decomposition of biomass. This renewable "bio-crude" serves three primary functions: it can be used directly as a substitute for industrial fuel oil in stationary applications, upgraded into transportation-grade biofuels like gasoline and diesel, or refined to extract valuable chemicals and materials.

Bio-oil represents a significant opportunity for renewable energy and chemicals, but its practical use is not straightforward. The key is to understand that raw bio-oil is an intermediate product, much like fossil crude oil, which requires processing and upgrading to overcome its inherent corrosiveness and instability before it can be integrated into existing infrastructure.

The Primary Applications for Bio-Oil

Bio-oil's flexibility allows it to fit into several parts of the energy and chemical value chains. Its application depends heavily on the level of processing and refinement it undergoes after production.

Direct Use as a Fuel Oil Substitute

The most immediate application for bio-oil is as a direct substitute for conventional fuel oils.

This is primarily for stationary applications like industrial boilers, furnaces, and large-scale power generation units. Its use in these contexts is governed by standards such as ASTM D7544, which specifies the required properties for pyrolysis oil used in burners.

A Feedstock for Transportation Fuels

Raw bio-oil is not a "drop-in" fuel for standard diesel or gasoline engines. It is too acidic and unstable.

However, it can be sent to existing refinery infrastructure for upgrading. Through processes like hydroprocessing, oxygen is removed and molecules are stabilized, converting the bio-crude into conventional hydrocarbon fuels. This pathway allows for the production of renewable gasoline, diesel, and jet fuel.

A Source for Renewable Chemicals and Materials

Beyond fuel, bio-oil is a complex mixture of valuable organic compounds.

It can be used as a chemical feedstock to produce specialty chemicals, resins, adhesives, and other materials. This approach treats the bio-oil not as a bulk fuel but as a source from which specific high-value components can be extracted and purified.

Understanding the Inherent Challenges of Raw Bio-Oil

The widespread adoption of bio-oil is limited by several technical hurdles associated with its raw, unprocessed state. Recognizing these challenges is crucial to understanding its real-world potential.

Corrosive Nature

Bio-oil is highly acidic, with a pH that can be damaging to standard pipes, pumps, and storage tanks made of common metals. This corrosiveness necessitates the use of specialized, corrosion-resistant materials for handling and transport.

Chemical Instability

Unlike stable petroleum crude, bio-oil is chemically reactive and can degrade over time. Exposure to heat can cause it to thicken, polymerize, and form solids, leading to clogging and fouling in engines and fuel lines. This low stability makes long-term storage a significant challenge.

High Viscosity and Impurities

Bio-oil typically has a higher viscosity than conventional fuels and contains a significant amount of water and solid char particles. These properties make it difficult to atomize in engines and can lead to incomplete combustion and equipment damage.

The Necessity of Upgrading

These challenges—corrosion, instability, and impurities—are why upgrading is a critical step for most high-value applications. Upgrading stabilizes the oil, removes corrosive oxygen, and makes it compatible with existing engines, pipelines, and refinery equipment.

Making the Right Choice for Your Goal

The optimal use of bio-oil depends entirely on your technical capabilities and end-use objective.

- If your primary focus is stationary power or heat generation: You can use bio-oil directly, but you must invest in specialized storage and combustion equipment designed to handle its corrosive and viscous nature.

- If your primary focus is producing advanced transportation biofuels: The goal is to integrate bio-oil as a feedstock into a refinery or upgrading facility, which requires significant capital investment in hydroprocessing technology.

- If your primary focus is developing green chemicals: Your strategy will involve sophisticated separation and purification techniques to extract high-value chemical compounds from the complex bio-oil mixture.

Ultimately, viewing bio-oil not as a finished product but as a renewable "bio-crude" is the key to unlocking its role in a more sustainable industrial landscape.

Summary Table:

| Application | Key Use | Main Consideration |

|---|---|---|

| Direct Fuel Substitute | Powering industrial boilers & furnaces | Requires corrosion-resistant equipment (ASTM D7544) |

| Transportation Biofuels | Upgraded to renewable gasoline, diesel, jet fuel | Needs hydroprocessing for stability & compatibility |

| Renewable Chemicals | Extracting valuable compounds for resins, adhesives | Involves separation & purification processes |

Ready to integrate pyrolysis bio-oil into your sustainable energy or chemical production? KINTEK specializes in providing robust lab equipment and consumables for biomass processing and bio-oil analysis. Whether you're researching fuel upgrading or chemical extraction, our solutions help you overcome challenges like corrosion and instability. Contact our experts today to find the right tools for your laboratory's needs!

Visual Guide

Related Products

- Aluminum Foil Current Collector for Lithium Battery

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Boron Nitride (BN) Ceramic Tube

- Vacuum Heat Treat Sintering Brazing Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- How do you test the capacity of a lithium-ion battery? A Guide to Accurate Measurement

- How will carbon nanotubes change the world? Powering the Green Revolution with Superior Materials

- What are two disadvantages of metal? Understanding Corrosion and Weight Limitations

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use

- Why is carbon coating important? Boost Battery Performance and Longevity