At its core, a grinding mill is a machine used to break solid materials into smaller pieces. This process, known as comminution, is a cornerstone of countless industrial sectors, from mining and cement manufacturing to food production and pharmaceuticals. Grinding mills are the primary tool for reducing the size of everything from large rocks down to microscopic powders, enabling a vast range of subsequent processes.

The true purpose of a grinding mill is not merely to make things smaller. It is a critical engineering tool used to increase a material's surface area, liberate valuable components, or achieve a specific particle size distribution required for a final product or downstream process.

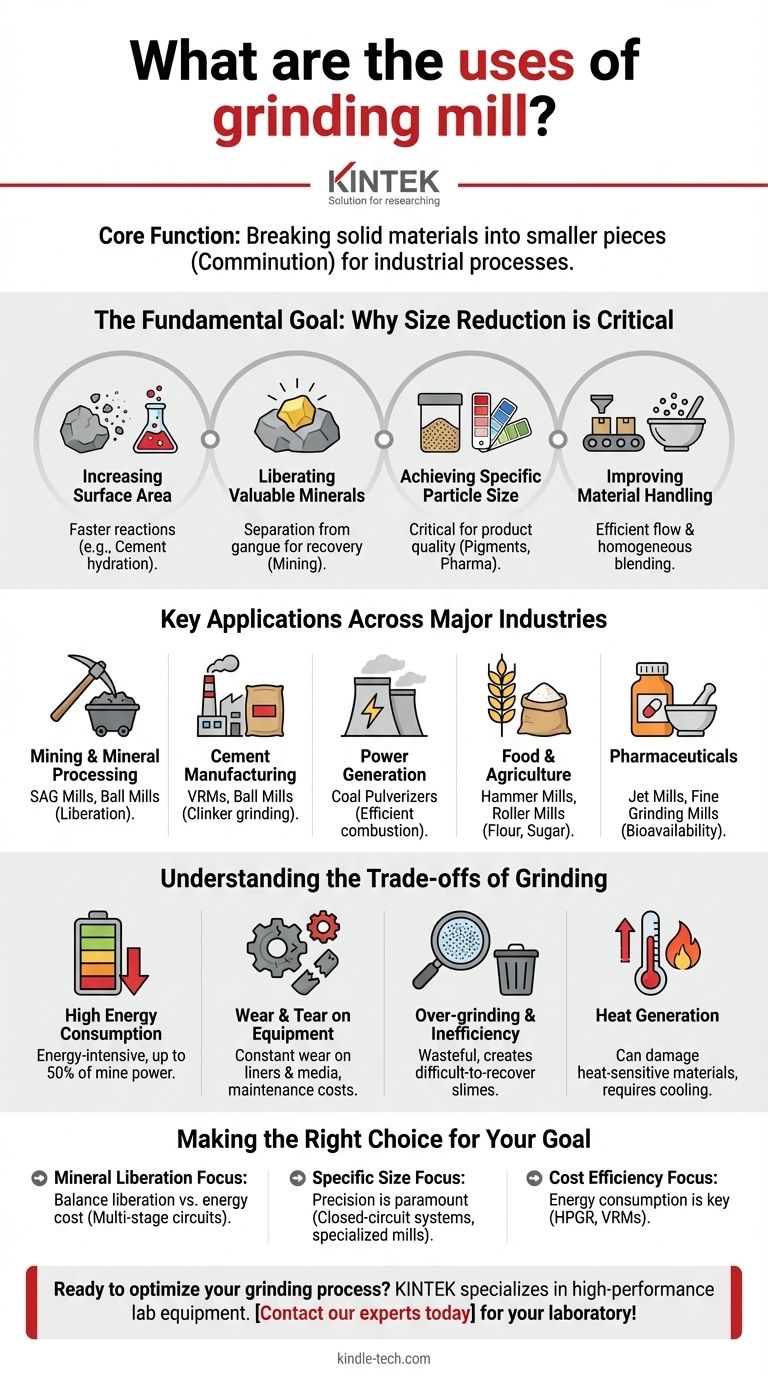

The Fundamental Goal: Why Size Reduction is Critical

Understanding the purpose of grinding requires looking beyond the physical act of breaking rocks. The goal is to change the material's properties in a way that unlocks value.

Increasing Surface Area for Reactions

When a solid material is ground, its total surface area increases exponentially. More surface area allows for faster and more complete chemical reactions.

A perfect example is in cement manufacturing. Clinker is ground into a fine powder to create cement. When mixed with water, the high surface area allows for a rapid hydration reaction, enabling the concrete to set and harden effectively.

Liberating Valuable Minerals from Ore

In the mining industry, valuable minerals like gold or copper are often trapped within a worthless host rock, known as gangue.

Grinding is the essential step that liberates the mineral particles from the gangue. By breaking the ore down to a size smaller than the mineral grains themselves, subsequent processes like flotation or leaching can efficiently separate and recover the valuable concentrate.

Achieving a Specific Particle Size for Final Products

For many products, the particle size is a critical quality specification. The feel, appearance, efficacy, and performance of the product depend entirely on achieving the correct size and distribution.

Think of pigments for paint, where particle size affects color and opacity, or pharmaceuticals, where the fine grinding of an active ingredient can dramatically improve its dissolution rate and bioavailability in the body.

Improving Material Handling and Blending

Fine, uniformly sized powders are often easier to handle, transport, and mix than coarse, irregular materials.

Processes like pneumatic conveying rely on consistent particle sizes for efficient flow. Furthermore, achieving a homogenous blend of different solid ingredients is far more successful when all components have been ground to a similar size range.

Key Applications Across Major Industries

While the principles are universal, the application of grinding mills is highly industry-specific.

Mining and Mineral Processing

This is the largest user of grinding mills globally. SAG (Semi-Autogenous Grinding) mills and Ball Mills are used in massive circuits to grind ore and liberate metals like copper, gold, iron, and platinum.

Cement Manufacturing

After the kiln, cement clinker is ground into a fine powder. Vertical Roller Mills (VRMs) and Ball Mills are the dominant technologies, chosen for their efficiency and ability to produce a consistent final product.

Power Generation

Coal-fired power plants use pulverizers (a type of grinding mill) to grind coal into a fine powder before it is blown into the furnace. This ensures rapid, complete combustion, maximizing energy output and minimizing emissions.

Food and Agriculture

Grinding is essential for producing flour from grains, powdered sugar from crystals, cocoa powder from nibs, and consistent formulations for animal feed. Various mills, from hammer mills to roller mills, are used.

Understanding the Trade-offs of Grinding

Grinding is a powerful process, but it is not without significant challenges and costs. Understanding these trade-offs is crucial for any operation.

High Energy Consumption

Comminution is notoriously energy-intensive. Grinding circuits can account for over 50% of a mine site's total power consumption. This makes energy efficiency a primary driver in mill selection and circuit design.

Wear and Tear on Equipment

The abrasive nature of the materials being ground causes constant wear on the mill's internal liners and the grinding media (such as steel balls or rods). This leads to significant maintenance costs, downtime, and consumption of spare parts.

Over-grinding and Inefficiency

Grinding a material finer than necessary is wasteful and can be counterproductive. In mineral processing, over-grinding can create ultra-fine particles ("slimes") that are difficult to recover, leading to a loss of valuable product.

Heat Generation

The mechanical energy of grinding generates significant heat. For heat-sensitive materials like certain chemicals, foods, or pharmaceuticals, this can damage the product, requiring specialized cooling systems or cryogenic grinding techniques.

Making the Right Choice for Your Goal

The optimal grinding strategy depends entirely on the primary objective of your process.

- If your primary focus is mineral liberation: Balance the degree of liberation against the high cost of energy, often using multi-stage circuits with SAG and Ball Mills to optimize throughput and recovery.

- If your primary focus is creating a final product with a specific size: Precision is paramount, often requiring closed-circuit systems with classifiers and specialized mills (like Vertical or Jet Mills) that offer tight control over particle size distribution.

- If your primary focus is cost efficiency in a bulk process: Energy consumption is your key metric, making technologies like High-Pressure Grinding Rolls (HPGR) or energy-efficient Vertical Roller Mills the most attractive options.

Ultimately, mastering a process that involves grinding begins with a clear understanding of why you are reducing the material's size in the first place.

Summary Table:

| Industry | Primary Use of Grinding Mill | Common Mill Types |

|---|---|---|

| Mining & Mineral Processing | Liberate valuable minerals from ore | SAG Mills, Ball Mills |

| Cement Manufacturing | Grind clinker into fine powder for rapid setting | Vertical Roller Mills (VRMs), Ball Mills |

| Power Generation | Pulverize coal for efficient combustion | Coal Pulverizers |

| Food & Agriculture | Produce flour, powdered sugar, animal feed | Hammer Mills, Roller Mills |

| Pharmaceuticals | Improve drug dissolution and bioavailability | Jet Mills, Fine Grinding Mills |

Ready to optimize your grinding process and boost efficiency? KINTEK specializes in high-performance lab equipment and consumables for all your grinding and milling needs. Whether you're in R&D or quality control, our solutions help you achieve precise particle size, improve product quality, and reduce energy costs. Contact our experts today to find the perfect grinding solution for your laboratory!

Visual Guide

Related Products

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

- Laboratory Jar Mill with Agate Grinding Jar and Balls

People Also Ask

- What is the product size of a ball mill? Achieve Micron-Level Precision for Your Materials

- What are the disadvantages of a ball mill? High Energy Use, Noise, and Contamination Risks

- What are the different types of laboratory mills? Choose the Right Grinder for Your Sample Material

- How does a laboratory ball mill contribute to the processing of solid polysilanes into coating powders?

- What is the role of a mechanical ball mill in the synthesis of glassy inorganic solid electrolytes (ISEs)?