The primary uses for pyrolysis oil are as a direct fuel substitute for industrial heating and as a raw feedstock for producing higher-value chemicals and upgraded fuels. Derived from the thermal decomposition of organic materials like biomass or waste plastic in the absence of oxygen, this oil serves as an intermediate energy product with significant, but challenging, potential.

Pyrolysis oil is best understood not as a finished product, but as a versatile bio-crude. While it can be burned directly for heat in specific industrial applications, its unique and often problematic chemical properties mean it requires specialized handling or significant upgrading to replace conventional hydrocarbon fuels.

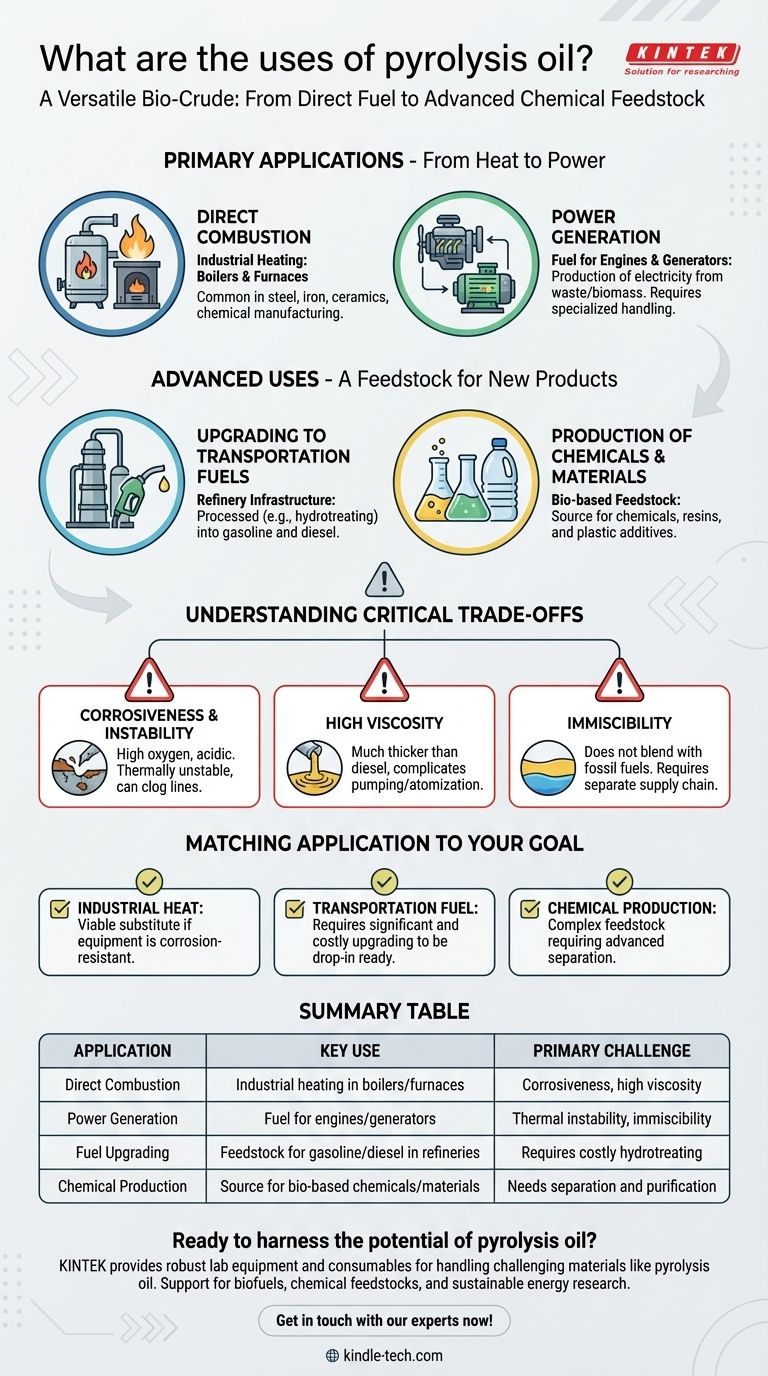

Primary Applications: From Heat to Power

Pyrolysis oil's most immediate use is as a substitute for conventional fuel oils in applications where heat or stationary power is the goal.

Direct Combustion for Heat and Power

Pyrolysis oil can be burned directly in boilers and industrial furnaces for process heat. This is a common application in industries like steel, iron, ceramics, and chemical manufacturing.

Its use as a substitute for conventional fuel oil in these stationary applications is its most mature use case, governed by standards like ASTM D7544.

Fuel for Engines and Generators

The oil can also be used as a fuel in diesel engines and large power generation units. This allows for the production of electricity from waste streams or biomass.

However, using it in engines is not a simple drop-in replacement and presents significant technical hurdles due to the oil's inherent properties.

Advanced Uses: A Feedstock for New Products

Beyond direct combustion, pyrolysis oil serves as a starting point for creating more refined products that integrate with existing energy and material infrastructure.

Upgrading to Transportation Fuels

A major area of development is upgrading the oil in existing refinery infrastructure. Through processes like hydrotreating, the raw pyrolysis oil can be converted into conventional hydrocarbon fuels like gasoline and diesel.

This approach leverages the massive scale of the petroleum industry to produce advanced biofuels from non-food sources.

Production of Chemicals and Materials

Pyrolysis oil is also a rich source of chemical compounds that can be extracted and used to produce bio-based chemicals, resins, and other materials.

It can also serve as an additive in the creation of various products, including plastics, reducing the reliance on fossil-fuel-based feedstocks.

Understanding the Critical Trade-offs

The widespread industrial application of pyrolysis oil is limited by its challenging chemical composition, which makes it fundamentally different from petroleum products.

Corrosiveness and Instability

The oil has a high oxygen content, which makes it acidic and corrosive to standard pipes, tanks, and engine components.

This oxygen content also makes the oil thermally unstable. When heated, it can polymerize—thicken and form solids—clogging fuel lines and injectors.

High Viscosity and Immiscibility

Pyrolysis oil typically has a high viscosity, meaning it is much thicker than diesel or heating oil, which complicates pumping and atomization for combustion.

Crucially, it is also immiscible with fossil fuels. This means it cannot be easily blended with conventional fuels and must be handled in a separate supply chain.

Matching the Application to Your Goal

Successfully using pyrolysis oil requires aligning its properties with the right application and being prepared to manage its technical challenges.

- If your primary focus is industrial heat generation: Pyrolysis oil is a viable substitute for heavy fuel oil in boilers and furnaces, provided your equipment is built with corrosion-resistant materials.

- If your primary focus is transportation fuel: Treat pyrolysis oil as a raw bio-crude that requires significant and costly upgrading before it can become a usable drop-in fuel.

- If your primary focus is chemical production: View the oil as a complex feedstock for extracting valuable bio-based compounds, which will require advanced separation and purification processes.

Ultimately, pyrolysis oil's value lies in its potential as a versatile intermediate product, provided its unique chemical challenges are properly engineered and managed.

Summary Table:

| Application | Key Use | Primary Challenge |

|---|---|---|

| Direct Combustion | Industrial heating in boilers/furnaces | Corrosiveness, high viscosity |

| Power Generation | Fuel for engines/generators | Thermal instability, immiscibility |

| Fuel Upgrading | Feedstock for gasoline/diesel in refineries | Requires costly hydrotreating |

| Chemical Production | Source for bio-based chemicals/materials | Needs separation and purification |

Ready to harness the potential of pyrolysis oil in your lab or process? KINTEK specializes in providing the robust lab equipment and consumables needed to safely handle, analyze, and develop applications for challenging materials like pyrolysis oil. Our expertise supports your research into biofuels, chemical feedstocks, and sustainable energy solutions. Contact us today to find the right tools for your project and let our specialists help you engineer around the unique challenges of bio-crude.

Get in touch with our experts now!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

- Thin-Layer Spectral Electrolysis Electrochemical Cell

People Also Ask

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success