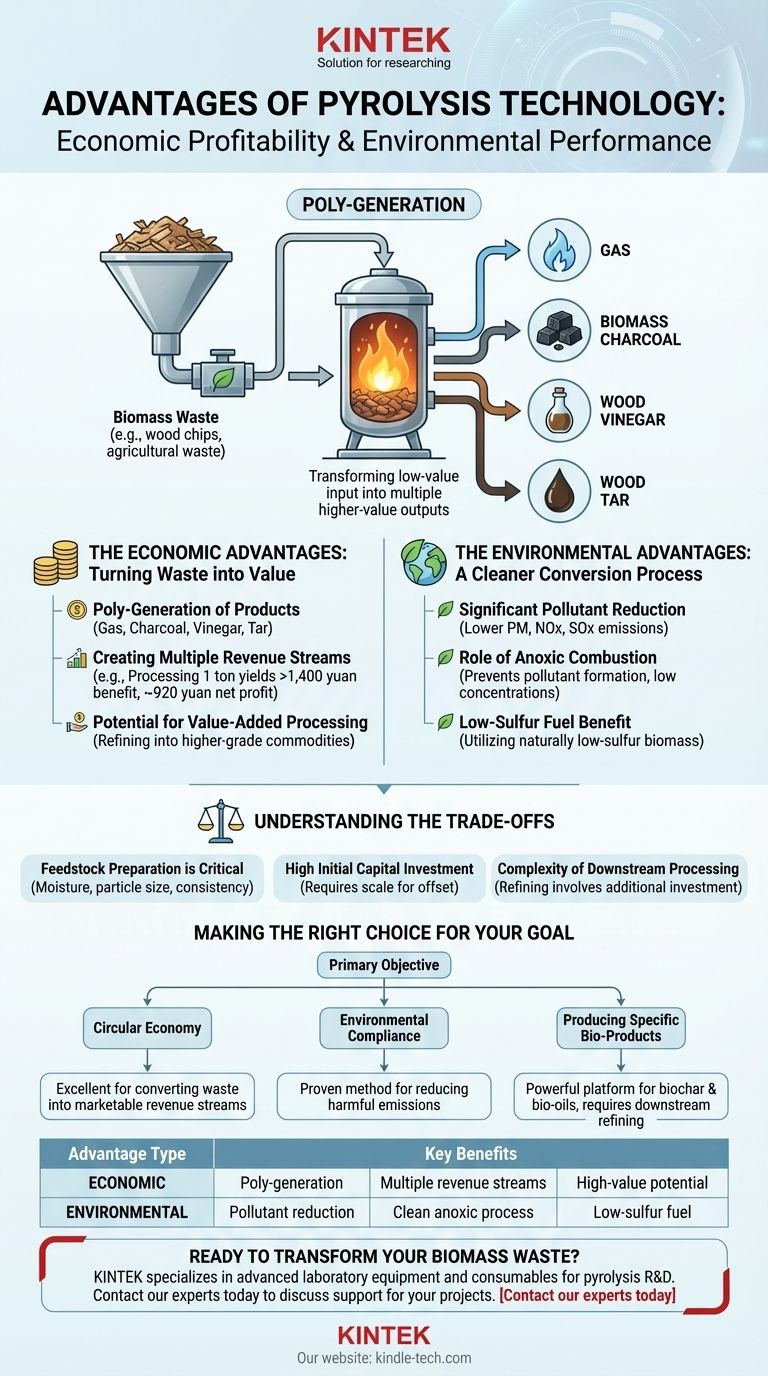

At its core, pyrolysis technology offers two significant, intertwined advantages: economic profitability and strong environmental performance. It is a process that converts biomass, such as wood chips or agricultural waste, into multiple valuable products simultaneously, creating revenue while significantly reducing the pollutant output compared to conventional combustion.

The fundamental advantage of pyrolysis is its ability to practice poly-generation—transforming a single, often low-value, input like biomass waste into several higher-value outputs (charcoal, gas, and liquids) in an environmentally clean process.

The Economic Advantages: Turning Waste into Value

Pyrolysis is not just a disposal method; it is a manufacturing process. It deconstructs raw biomass into a portfolio of commercially viable products.

Poly-Generation of Products

The system is designed to produce gas, biomass charcoal, wood vinegar, and wood tar from a single feedstock. Each of these outputs has its own market and applications.

Creating Multiple Revenue Streams

This multi-output nature diversifies income. For example, processing one ton of wood chips can yield a combination of products with a direct financial benefit of over 1,400 yuan, resulting in a net profit of around 920 yuan after accounting for costs.

Potential for Value-Added Processing

The initial products are just the beginning. The raw charcoal, gas, and liquids can be further refined into higher-grade commodities, potentially increasing their market value several times over.

The Environmental Advantages: A Cleaner Conversion Process

Pyrolysis offers a clear pathway to reducing the environmental impact of biomass utilization, primarily by avoiding the pitfalls of direct burning.

Significant Pollutant Reduction

The process results in lower emissions of harmful pollutants, including particulate matter, nitrogen oxides (NOx), and sulfides (SOx).

The Role of Anoxic Combustion

Pyrolysis heats the biomass in an oxygen-starved environment ("anoxic layer combustion"). This prevents the formation of pollutants that are common in open burning, leading to much lower concentrations of particulate matter and NOx in the exhaust.

Low-Sulfur Fuel Benefit

When using biomass like wood chips or straw, the fuel source is naturally low in sulfur. This inherent quality, combined with the pyrolysis process, ensures that sulfide emissions are minimal and typically fall well within national control standards.

Understanding the Trade-offs

While the benefits are clear, adopting pyrolysis technology requires a realistic understanding of its operational complexities and requirements.

Feedstock Preparation is Critical

The efficiency of a pyrolysis system is highly dependent on the input material. Factors like moisture content, particle size, and chemical consistency of the biomass must be carefully managed to achieve optimal results.

High Initial Capital Investment

Building a pyrolysis gasification plant is a significant capital expenditure. The economic benefits described are contingent on achieving a certain scale of operation to offset the initial investment and fixed operating costs.

Complexity of Downstream Processing

While the potential for value-added products is a major advantage, realizing that potential requires additional investment. Refining raw bio-oil or tar into specialized chemicals or fuels involves complex and often costly downstream processing infrastructure.

Making the Right Choice for Your Goal

To determine if pyrolysis is the correct solution, you must align the technology's strengths with your primary objective.

- If your primary focus is creating a circular economy: Pyrolysis is an excellent choice for converting low-value biomass waste into multiple, marketable revenue streams.

- If your primary focus is environmental compliance: The technology offers a proven method for reducing harmful emissions far below the levels of traditional combustion.

- If your primary focus is producing specific bio-products: Pyrolysis is a powerful platform for generating biochar and bio-oils, but be prepared to invest in the downstream refining needed to create finished goods.

Ultimately, pyrolysis empowers organizations to view biomass not as waste to be disposed of, but as a resource to be transformed.

Summary Table:

| Advantage Type | Key Benefits |

|---|---|

| Economic | Poly-generation of multiple products (char, gas, oil), Creates multiple revenue streams, Potential for high-value product refinement |

| Environmental | Significant reduction in pollutants (PM, NOx, SOx), Clean anoxic combustion process, Utilizes low-sulfur biomass fuel |

Ready to transform your biomass waste into a profitable, sustainable resource?

KINTEK specializes in providing advanced laboratory equipment and consumables for pyrolysis research and development. Whether you are optimizing your process or scaling up production, our solutions help you achieve precise control and maximize your output of valuable bio-products.

Contact our experts today to discuss how KINTEK can support your pyrolysis projects and help you build a circular economy.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time