In essence, biomass fast pyrolysis is a high-temperature thermal process that rapidly deconstructs organic material, like wood or agricultural waste, in an environment without oxygen. This technique uses extremely high heating rates and very short reaction times—typically less than two seconds—to convert solid biomass primarily into a liquid fuel known as bio-oil, along with smaller amounts of solid bio-char and combustible syngas.

The central goal of fast pyrolysis is to maximize the production of liquid bio-oil. It achieves this by heating biomass so quickly that it vaporizes before it can break down into simpler components, then rapidly cooling—or "quenching"—those vapors to condense them into a liquid.

The Core Principle: Thermal Deconstruction Without Burning

To understand fast pyrolysis, it's essential to distinguish it from combustion. Burning requires oxygen, whereas pyrolysis intentionally starves the reaction of oxygen to break the material down rather than incinerate it.

The Composition of Biomass

Biomass is primarily composed of three complex organic polymers: cellulose, hemicellulose, and lignin. The goal of pyrolysis is to break the chemical bonds within these structures to create smaller, more useful molecules.

The Role of Heat and Oxygen Deprivation

By heating biomass to between 400-550°C in an oxygen-free reactor, the long polymer chains are thermally fractured. The absence of oxygen is critical; it ensures the material decomposes into valuable vapors, liquids, and solids instead of simply burning into ash and flue gas.

The Conditions that Define "Fast" Pyrolysis

Three conditions separate fast pyrolysis from other thermal methods:

- High Heating Rate: The biomass particles are heated extremely quickly.

- Short Residence Time: The material and its resulting vapors are only in the hot reaction zone for less than two seconds.

- Rapid Quenching: The hot vapors are cooled immediately to prevent them from further reacting and breaking down into less valuable gases.

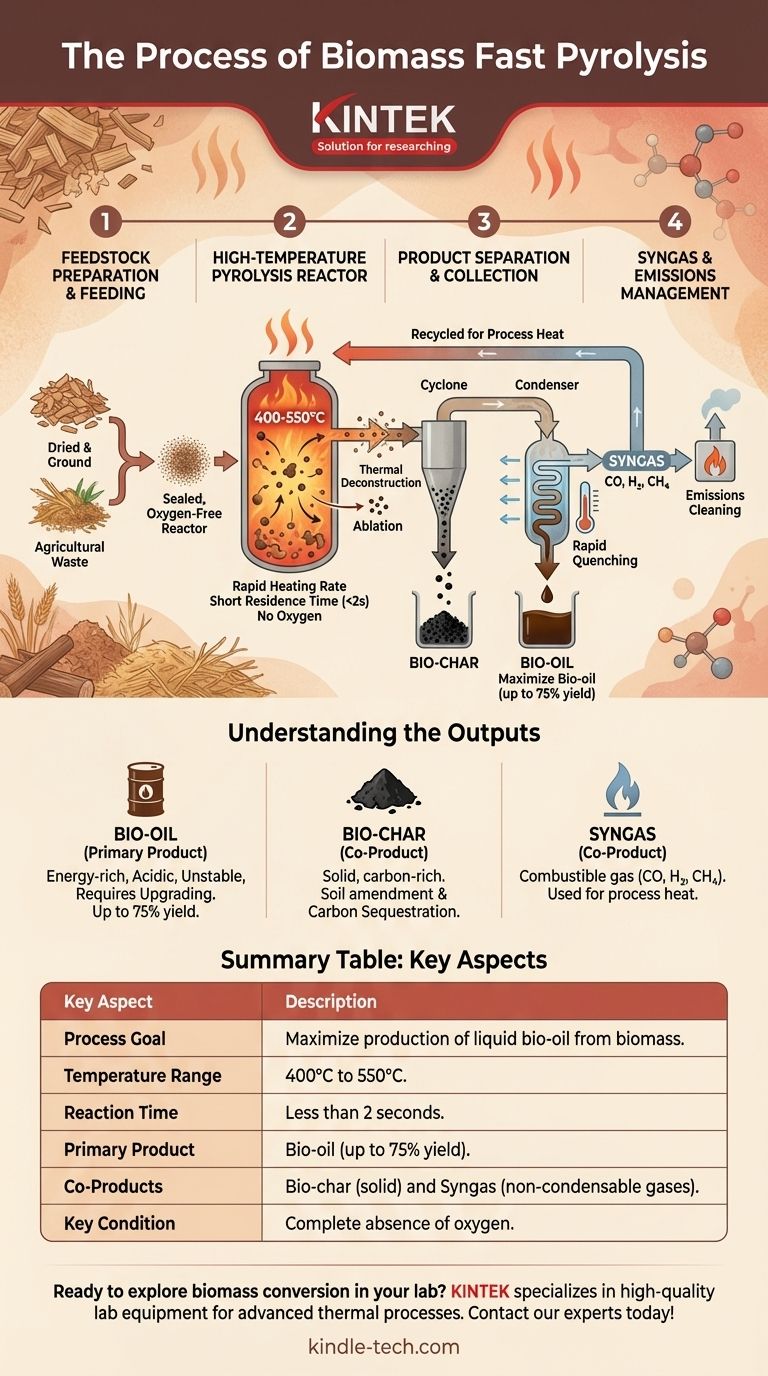

A Step-by-Step Look Inside a Pyrolysis Plant

A typical fast pyrolysis facility operates as a continuous process, moving from raw biomass to finished products through several distinct stages.

Stage 1: Feedstock Preparation and Feeding

The process begins with preparing the raw biomass. It must be dried to a low moisture content and ground into fine particles to ensure it can be heated rapidly and uniformly. This prepared material is then fed into a sealed, oxygen-free reactor system.

Stage 2: The High-Temperature Pyrolysis Reactor

Inside the reactor, the fine biomass particles are exposed to intense heat. The extremely high heat transfer rate causes the particles to decompose almost instantly, a process called ablation, converting the solid directly into hot vapors and aerosols, along with a solid char residue.

Stage 3: Product Separation and Collection

The stream of hot vapors, aerosols, and char particles immediately exits the reactor. The solid bio-char is separated out using cyclones. The remaining hot gas stream is then rapidly cooled in a condenser, which liquefies the majority of the vapors into bio-oil.

Stage 4: Syngas and Emissions Management

Any vapors that do not condense form a stream of non-condensable gases, or syngas. This gas is rich in carbon monoxide, hydrogen, and methane. It is typically recycled back to provide the heat for the reactor, making the process partially self-sustaining. Any final emissions are cleaned to meet environmental regulations.

Understanding the Trade-offs and Outputs

While powerful, fast pyrolysis is not a perfect solution. The primary goal is to maximize one product (bio-oil), which comes at the expense of others and introduces unique challenges.

The Primary Product: Bio-oil

The main output, bio-oil (or pyrolysis oil), is a dark, dense liquid. It is an energy-rich fuel, but it is also acidic, corrosive, and chemically unstable, meaning it often requires further upgrading before it can be used as a drop-in replacement for conventional fuels.

The Co-Products: Bio-char and Syngas

Bio-char is a solid, carbon-rich material similar to charcoal. While fast pyrolysis produces less char than slow pyrolysis, this co-product is valuable for soil amendment and carbon sequestration. The syngas produced is almost always used to power the plant itself, reducing external energy needs.

Process Sensitivity

Fast pyrolysis systems are highly sensitive to the feedstock. The moisture content and particle size of the incoming biomass must be tightly controlled to maintain the rapid heating and short reaction times necessary for high bio-oil yields.

Making the Right Choice for Your Goal

The decision to use fast pyrolysis depends entirely on the desired end product. It is a specialized process optimized for a specific outcome.

- If your primary focus is liquid fuel production: Fast pyrolysis is the superior technology, as it is engineered to maximize bio-oil yields, often reaching up to 75% of the product weight.

- If your primary focus is creating stable charcoal for soil: Slow pyrolysis is the better choice, as its long residence times and lower temperatures are designed to maximize the output of solid bio-char.

- If your primary focus is generating electricity or heat: Gasification, a related process that uses a small amount of oxygen, is often more direct as it is optimized to convert nearly all the biomass into combustible syngas.

By understanding that fast pyrolysis is a tool precision-engineered for liquid fuel generation, you can effectively determine its role in converting biomass into valuable resources.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Goal | Maximize production of liquid bio-oil from biomass. |

| Temperature Range | 400°C to 550°C. |

| Reaction Time | Less than 2 seconds. |

| Primary Product | Bio-oil (up to 75% yield). |

| Co-Products | Bio-char (solid) and Syngas (non-condensable gases). |

| Key Condition | Complete absence of oxygen. |

Ready to explore biomass conversion in your lab? KINTEK specializes in high-quality lab equipment and consumables for advanced thermal processes like pyrolysis. Whether you're researching bio-oil yields or optimizing reactor conditions, our solutions are designed for precision and reliability. Contact our experts today to discuss how we can support your laboratory's biomass energy projects.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Dental Porcelain Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs