One of the most significant disadvantages of biomass energy is that it is not a truly "clean" energy source. While often categorized as renewable, the process of burning organic matter releases harmful air pollutants and greenhouse gases, and its large-scale implementation can lead to significant environmental degradation like deforestation and land degradation.

The core issue with biomass energy is the gap between its "renewable" label and its real-world impact. Its viability is critically dependent on sustainable sourcing, and it carries substantial trade-offs related to land use, air quality, and overall cost-effectiveness that are often overlooked.

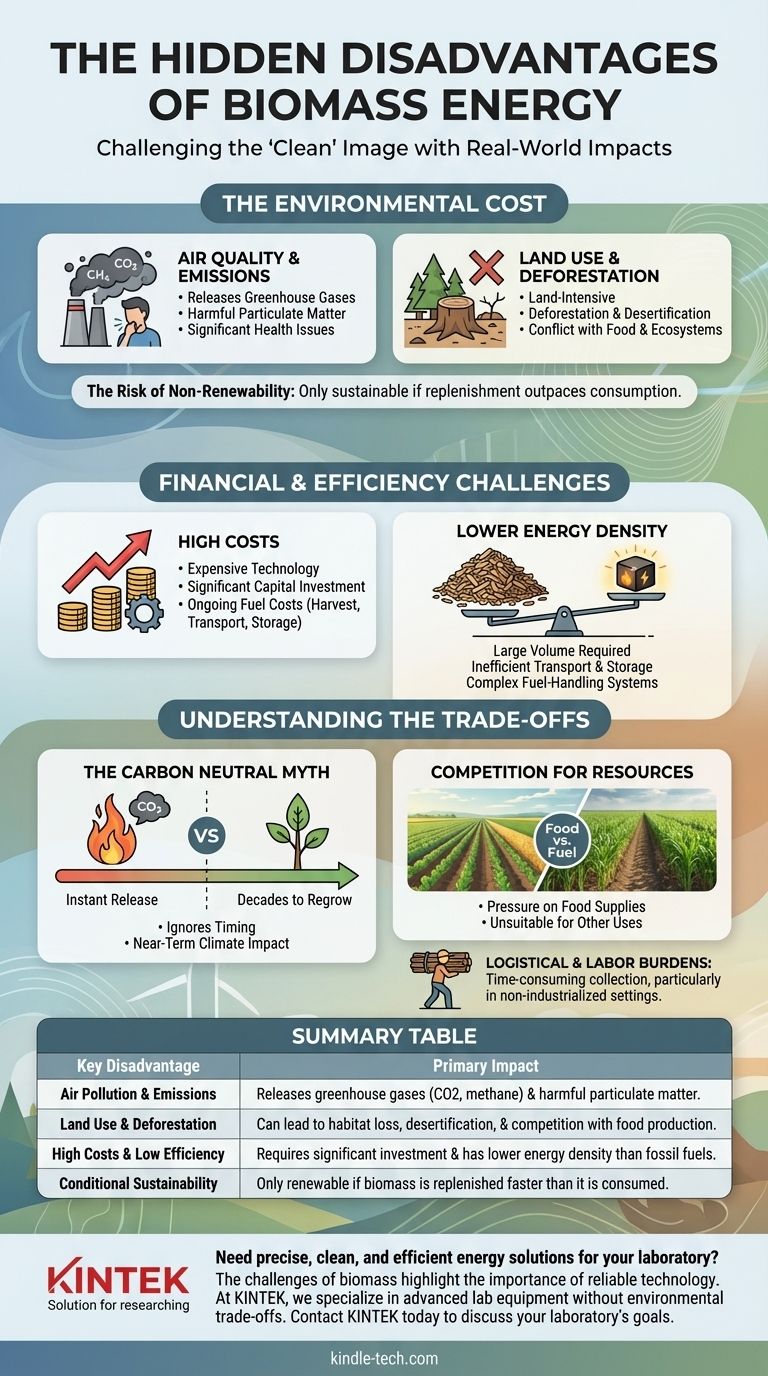

The Environmental Cost of Biomass

While derived from organic matter, converting biomass to energy carries a heavy environmental footprint that challenges its "green" reputation.

Air Quality and Emissions

Burning any organic material, whether wood, crops, or waste, releases pollutants into the atmosphere.

This includes harmful gases like carbon dioxide (CO2) and methane, which are potent greenhouse gases.

The smoke also contains particulate matter that can cause significant health issues for people living near biomass facilities.

Land Use and Deforestation

Biomass power generation is land-intensive. It requires vast areas to grow energy crops or relies on the harvesting of forests.

If not managed with extreme care, this can lead to deforestation, desertification, and general land degradation.

This creates a direct conflict between using land for fuel, for food production, or for preserving natural ecosystems.

The Risk of Non-Renewability

The "renewable" status of biomass is conditional. It is only sustainable if the organic matter is replenished at the same rate it is consumed.

When forests are cut down faster than they can regrow, biomass ceases to be renewable and becomes a net contributor to environmental harm.

Unpacking the Financial and Efficiency Challenges

Beyond the environmental concerns, biomass faces significant practical hurdles related to its cost and the inherent properties of its fuel source.

High Initial and Operational Costs

Building and maintaining a biomass power plant requires expensive technology and a significant capital investment.

Furthermore, the costs associated with harvesting, collecting, transporting, and storing bulky biomass fuel are substantial and ongoing.

Lower Energy Density

Compared to fossil fuels, biomass has a low energy density. This means a much larger volume and weight of biomass is required to produce the same amount of energy as a smaller amount of coal or natural gas.

This inefficiency drives up transportation and storage costs and requires a larger, more complex fuel-handling system.

Understanding the Trade-offs

Evaluating biomass energy requires moving beyond simple labels and confronting its inherent compromises.

The "Carbon Neutral" Myth

Biomass is often called "carbon neutral" because the carbon released when it's burned was previously absorbed from the atmosphere by the plant.

However, this argument ignores timing. Burning releases carbon instantly, while it takes a forest decades to regrow and reabsorb that same amount of carbon. This creates a significant, near-term impact on the climate.

Competition for Resources

The need for land creates a direct competition between growing crops for fuel versus growing crops for food.

This can put pressure on food supplies and prices, particularly in developing regions. Land dedicated to energy crops also becomes unsuitable for other uses.

Logistical and Labor Burdens

In many contexts, collecting suitable biomass is a time-consuming and labor-intensive process.

This is particularly true in non-industrialized settings, where the burden of collecting fuelwood can fall heavily on local populations.

Making the Right Choice for Your Goal

Whether biomass is a disadvantage depends entirely on the specific application and goal.

- If your primary focus is large-scale, clean electricity generation: Biomass is often less suitable than solar, wind, or geothermal due to its emissions, land requirements, and lower efficiency.

- If your primary focus is waste reduction: Using agricultural, forestry, or municipal waste for biomass energy can be a highly effective way to generate value from materials that would otherwise decompose and release methane.

- If your primary focus is local, off-grid energy: Small-scale biomass systems can be viable, provided they are fueled by sustainably managed, local resources without depleting the natural environment.

Ultimately, the effectiveness of biomass energy is defined by a rigorous and honest assessment of its true lifecycle costs.

Summary Table:

| Key Disadvantage | Primary Impact |

|---|---|

| Air Pollution & Emissions | Releases greenhouse gases (CO2, methane) and harmful particulate matter. |

| Land Use & Deforestation | Can lead to habitat loss, desertification, and competition with food production. |

| High Costs & Low Efficiency | Requires significant investment and has lower energy density than fossil fuels. |

| Conditional Sustainability | Only renewable if biomass is replenished faster than it is consumed. |

Need precise, clean, and efficient energy solutions for your laboratory? The challenges of biomass energy highlight the importance of reliable and sustainable technology. At KINTEK, we specialize in advanced lab equipment that delivers accuracy and efficiency without the environmental trade-offs. Let our experts help you find the right solution for your specific energy and research needs. Contact KINTEK today to discuss how we can support your laboratory's goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Evaporation Boat for Organic Matter

People Also Ask

- What are the constituents of pyrolysis oil? Unlocking the Complex Chemistry of Bio-Oil

- Is sintering the same as melting? Master the Critical Thermal Process Distinction

- What are the heating rate requirements for a fast pyrolysis furnace? Achieve Max Bio-Oil Yield with Rapid Thermal Shock

- Is brazing a permanent joint? Yes, and here's why it's stronger than you think.

- How does heat affect strength materials? The Science of Thermal Degradation Explained

- How does a high-precision temperature control heating system facilitate the study of stainless steel corrosion?

- What is the charcoal yield in fast pyrolysis? A Low-Yield Feature for Maximum Bio-Oil

- What is sputtering process in AAS? A Guide to Thin Film Deposition Technology