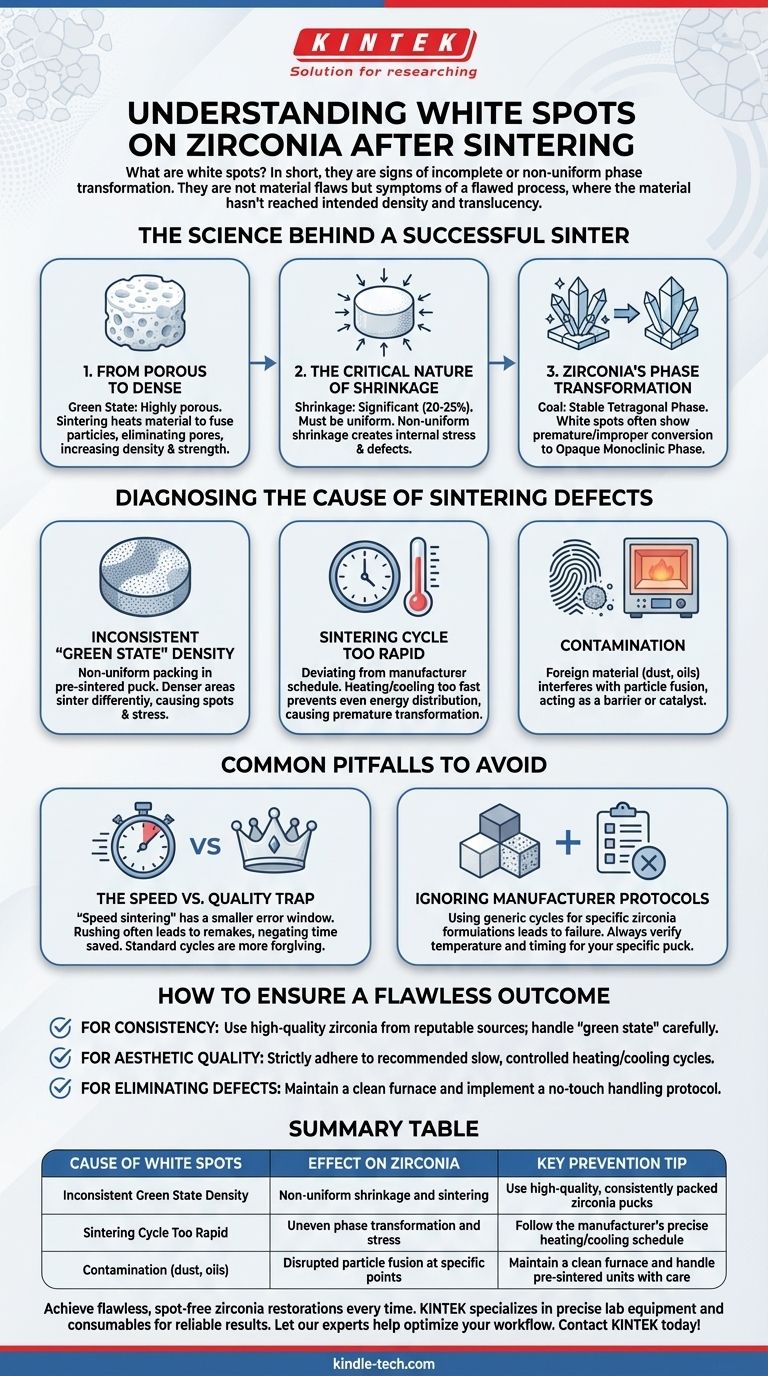

In short, white spots on zirconia after sintering are typically a sign of an incomplete or non-uniform phase transformation. They represent localized areas where the material has not reached its intended final state of density and translucency, often due to issues with the material's initial state or the sintering cycle itself.

The appearance of white spots is not a material flaw in the zirconia itself, but rather a symptom of a flaw in the process. Achieving a flawless, monolithic result depends entirely on ensuring uniform density before sintering and maintaining precise control over the heating and cooling cycle.

The Science Behind a Successful Sinter

Zirconia's transformation from a porous, chalky "green state" to a dense, strong ceramic is a delicate process. Understanding the core principles reveals why defects like white spots can occur.

From Porous to Dense

Before heating, a milled zirconia restoration is highly porous. The purpose of sintering is to eliminate these pores by heating the material to a point where the individual particles fuse together.

This process dramatically increases the material's density and overall strength, as highlighted in the provided references.

The Critical Nature of Shrinkage

As the pores are eliminated, the entire restoration shrinks significantly, often by 20-25%. This shrinkage must be perfectly uniform across the entire volume of the material.

If one area sinters and shrinks faster than an adjacent area, it creates immense internal stress, which can manifest as defects.

Zirconia's Phase Transformation

The most crucial step is the crystalline phase transformation. Zirconia must maintain a stable tetragonal phase in its final state for optimal strength and aesthetics.

White spots are often areas where the material has prematurely or improperly converted to the monoclinic phase. This phase is more opaque and has a different volume, creating a visible and structural inconsistency.

Diagnosing the Cause of Sintering Defects

White spots are a diagnostic tool. They tell you that something in the preparation or heating process was not uniform. The most common culprits fall into a few key categories.

Inconsistent "Green State" Density

The most common cause of non-uniform sintering is non-uniform density in the pre-sintered zirconia. If the material is not packed consistently in its puck, some areas will be denser than others.

These denser areas will sinter differently than the less-dense areas, leading to visible spots and internal stress.

Sintering Cycle Too Rapid

Every zirconia manufacturer provides a precise, tested sintering schedule. Deviating from this by heating or cooling too quickly is a primary cause of defects.

A rapid cycle does not allow thermal energy to distribute evenly, causing some parts of the restoration to transform before others. This is a guaranteed way to create opacity and white spots.

Contamination

Any foreign material, from dust in the furnace to oils from handling, can interfere with the sintering process at a specific point on the restoration's surface.

This contamination can act as a barrier or a catalyst, disrupting the uniform fusion of zirconia particles and leaving a visible mark.

Common Pitfalls to Avoid

Achieving perfect results requires avoiding the temptation of shortcuts that compromise the integrity of the material.

The Speed vs. Quality Trap

"Speed sintering" cycles are available, but they operate within a much smaller window for error. A standard, slower cycle is far more forgiving and consistently produces better results.

Rushing the process is the most common reason for remakes, completely negating any time saved.

Ignoring Manufacturer Protocols

Different zirconia formulations (e.g., high-strength vs. high-translucency) have different ideal sintering parameters. Using a generic or incorrect cycle for a specific material is a frequent source of failure.

Always verify the exact temperature and timing requirements for the specific puck you are using.

How to Ensure a Flawless Outcome

Your approach to the sintering process directly determines the quality of the final restoration. A meticulous, controlled process is the only way to achieve predictable, aesthetic results.

- If your primary focus is consistency: Ensure you are using high-quality zirconia from a reputable source and that your "green state" restorations are handled carefully to avoid creating density variations.

- If your primary focus is aesthetic quality: Adhere strictly to the manufacturer's recommended sintering cycle, prioritizing a slow, controlled heating and cooling rate over speed.

- If your primary focus is eliminating defects: Maintain a scrupulously clean sintering furnace and implement a no-touch handling protocol for pre-sintered units to prevent any form of contamination.

Ultimately, preventing white spots and other defects requires treating sintering not as a simple heating step, but as a precise materials science procedure.

Summary Table:

| Cause of White Spots | Effect on Zirconia | Key Prevention Tip |

|---|---|---|

| Inconsistent Green State Density | Non-uniform shrinkage and sintering | Use high-quality, consistently packed zirconia pucks |

| Sintering Cycle Too Rapid | Uneven phase transformation and stress | Follow the manufacturer's precise heating/cooling schedule |

| Contamination (dust, oils) | Disrupted particle fusion at specific points | Maintain a clean furnace and handle pre-sintered units with care |

Achieve flawless, spot-free zirconia restorations every time. White spots are a sign of process inconsistency. KINTEK specializes in the precise lab equipment and consumables your laboratory needs for reliable results. Our range of high-performance sintering furnaces and high-quality zirconia materials ensures the uniform heating and material integrity required for perfect outcomes. Let our experts help you optimize your workflow. Contact KINTEK today to discuss your specific laboratory requirements!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Can ceramic teeth stain? Why High-Quality Dental Ceramics Resist Discoloration

- What are the different types of dental furnaces? Choose the Right Furnace for Your Dental Lab

- How do the thermal properties of zirconia substructures influence firing and cooling? Expert Thermal Management Guide

- How can a porcelain furnace be calibrated using a visual indicator approach? Master Material-Specific Accuracy

- What temperature is porcelain fired at? A Guide to Precise Dental Firing Cycles

- What types of materials can a Dental Press Furnace process? Versatile Solutions for High-Performance Ceramics

- What is a ceramic dental furnace? A Precision Tool for Durable, Aesthetic Restorations

- Can a broken porcelain tooth be repaired? A Guide to Durable Dental Solutions