In essence, a vast range of organic materials can serve as feedstock for pyrolysis. The most common sources are broadly categorized into agricultural residues like corn stover and rice husks, woody biomass from forestry and construction waste, and the organic portion of municipal solid waste. The viability of any specific biomass depends on its chemical composition, moisture content, local availability, and the cost of collection and processing.

The critical question is not just what biomass can be used, but which biomass is most effective for a specific goal. The ideal feedstock is determined by its inherent properties and how they align with the desired primary product—whether that be bio-oil, biochar, or gas.

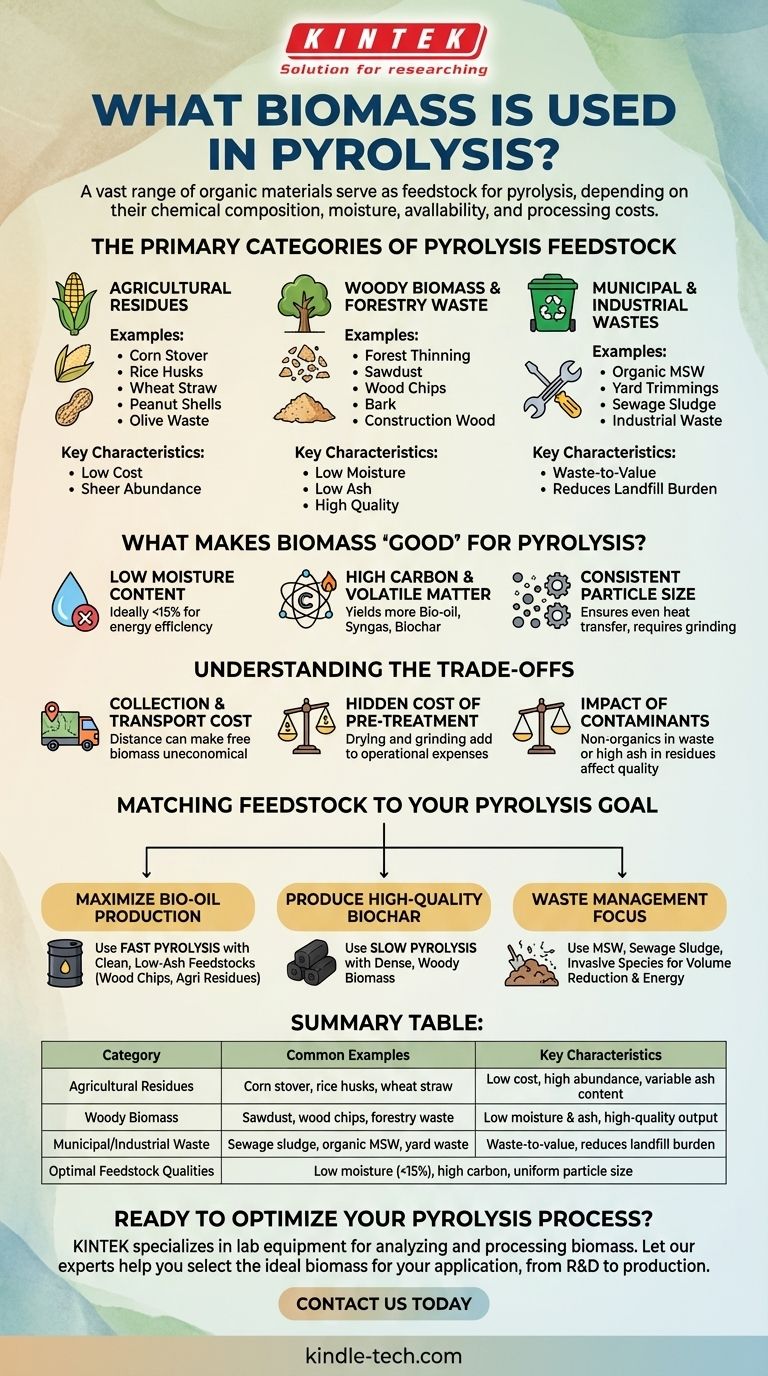

The Primary Categories of Pyrolysis Feedstock

Pyrolysis is fundamentally a process of thermal decomposition in an oxygen-free environment. This means any material with a high organic content is a potential candidate. These candidates generally fall into three main groups.

Agricultural Residues

This is one of the largest and most readily available sources of biomass globally. It includes the stalks, leaves, and husks left over after a harvest.

Common examples include corn stover and stalks, wheat straw, rice husks, peanut shells, and coffee or olive processing waste. Their primary advantage is low cost and sheer abundance.

Woody Biomass and Forestry Waste

Woody biomass is often considered a high-quality feedstock due to its low moisture and ash content compared to agricultural residues.

This category includes everything from forest thinning and tree branches to industrial wood waste like sawdust, wood chips, and bark from sawmills. It also includes clean, untreated wood from construction and demolition activities.

Municipal and Industrial Wastes

This category leverages the "waste-to-value" potential of pyrolysis, converting problematic waste streams into useful products.

Key examples are the organic fraction of municipal solid waste (MSW), yard trimmings, and industrial wastes like sewage sludge. Using these materials not only produces energy but also reduces landfill burdens.

What Makes Biomass "Good" for Pyrolysis?

While many organic materials can be used, several key characteristics define an optimal feedstock that will deliver an efficient process and high-quality output.

Low Moisture Content

Energy must be spent to evaporate any water in the biomass before pyrolysis can begin. Feedstocks with lower moisture content (ideally below 15%) are far more energy-efficient and lead to a higher net energy yield.

High Carbon and Volatile Matter Content

The goal of pyrolysis is to break down organic compounds into valuable products. Biomass with a high carbon and volatile matter content will naturally yield more bio-oil, syngas, and biochar.

Consistent Particle Size

For the chemical reaction to occur evenly and efficiently within the reactor, the feedstock must be of a relatively uniform size. This ensures consistent heat transfer and prevents operational issues, meaning most raw biomass requires grinding or chipping.

Understanding the Trade-offs

Selecting a feedstock is an exercise in balancing ideal characteristics with practical and economic realities. Ignoring these trade-offs is a common pitfall.

The Cost of Collection and Transport

The "best" biomass from a technical standpoint may not be the most economical. A feedstock might be free, but if it is located far from the pyrolysis plant, transportation costs can make it unfeasible. This is why plants are often co-located with sources like sawmills or large farms.

The Hidden Cost of Pre-treatment

Virtually no raw biomass is "reactor-ready." It almost always requires drying and grinding to achieve the necessary moisture content and particle size. These pre-treatment steps require energy, equipment, and operational expense that must be factored into the overall cost.

The Impact of Contaminants

Waste streams like MSW can contain non-organic contaminants (plastics, metals, glass) that must be removed. Likewise, agricultural residues can have high soil or ash content, which remains in the biochar and can lower its quality or cause operational issues.

Matching Feedstock to Your Pyrolysis Goal

The optimal feedstock choice is directly tied to the primary product you aim to create. Different processes and feedstocks favor different outputs.

- If your primary focus is maximizing bio-oil production: Use fast pyrolysis with clean, low-ash feedstocks like wood chips or certain agricultural residues to maximize liquid fuel yield.

- If your primary focus is producing high-quality biochar: Use slow pyrolysis with dense, woody biomass, as this process is optimized for a higher yield of the solid carbon product.

- If your primary focus is waste management: MSW, sewage sludge, or invasive plant species are excellent candidates where volume reduction and diverting waste from landfills is the main goal, with energy production as a valuable byproduct.

By understanding these principles, you can select a biomass feedstock that aligns perfectly with your technical and economic objectives.

Summary Table:

| Category | Common Examples | Key Characteristics |

|---|---|---|

| Agricultural Residues | Corn stover, rice husks, wheat straw | Low cost, high abundance, variable ash content |

| Woody Biomass | Sawdust, wood chips, forestry waste | Low moisture & ash, high-quality output |

| Municipal/Industrial Waste | Sewage sludge, organic MSW, yard waste | Waste-to-value, reduces landfill burden |

| Optimal Feedstock Qualities | - | Low moisture (<15%), high carbon, uniform particle size |

Ready to optimize your pyrolysis process with the right feedstock?

KINTEK specializes in lab equipment and consumables for analyzing and processing biomass. Whether your goal is to maximize bio-oil yield, produce high-quality biochar, or manage waste streams effectively, our solutions help you characterize feedstock properties and scale your operations efficiently.

Let our experts help you select the ideal biomass for your specific application. Contact us today to discuss your laboratory needs and discover how KINTEK can support your pyrolysis projects from R&D to production.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the types of pyrolysis reactors used in industry? Choose the Right Technology for Your Product

- What are the different types of reactors in plastic pyrolysis? Choose the Right System for Your Waste

- What are the products of pyrolysis of wood? A Guide to Biochar, Bio-oil, and Syngas Yields

- What is the purpose of a calciner? Boost Efficiency in High-Temperature Processing

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing