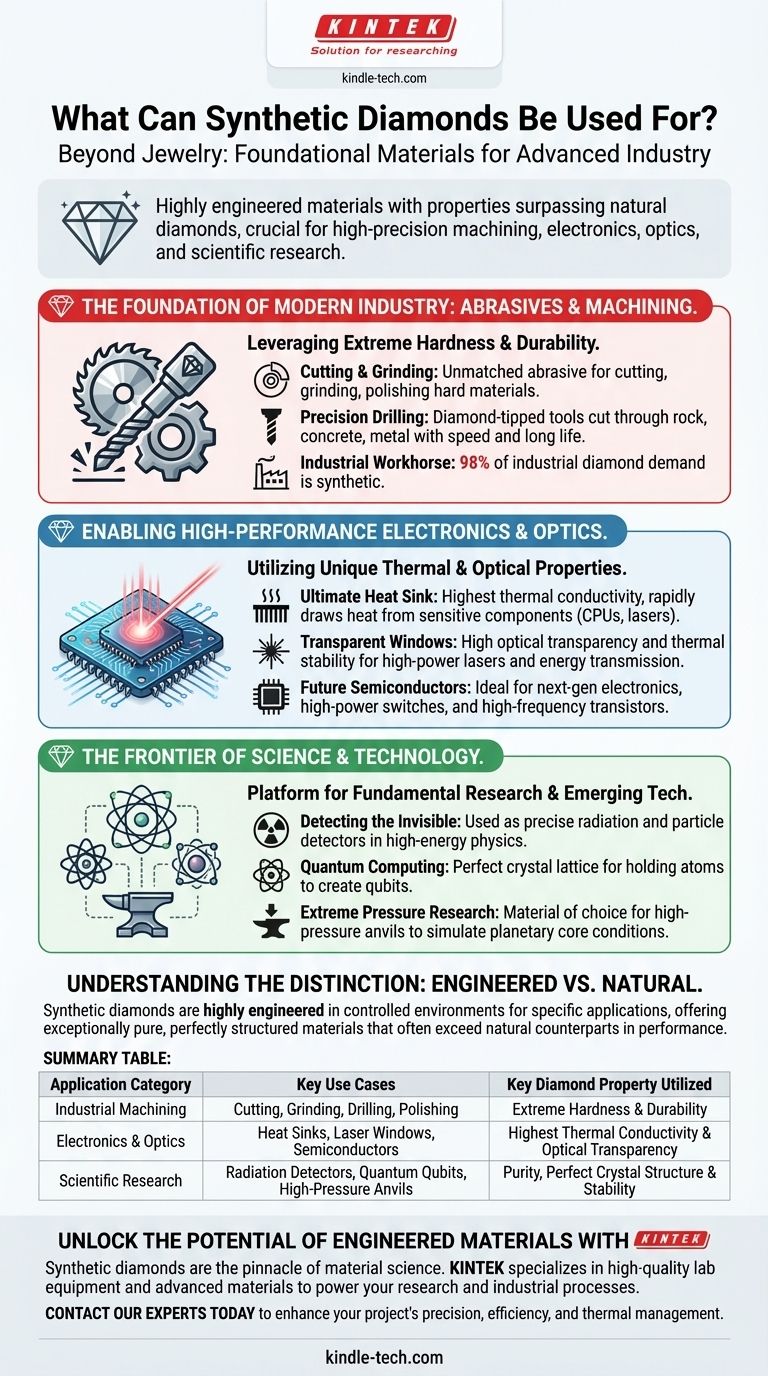

Beyond the jewelry store, synthetic diamonds are foundational materials in nearly every advanced industry. Their primary uses span high-precision machining, cutting-edge electronics, high-power optics, and scientific research, leveraging properties like extreme hardness and thermal conductivity that often surpass those of natural diamonds.

The crucial insight is that synthetic diamonds are not mere imitations; they are highly engineered materials. Their value comes from the ability to precisely control their properties, creating a substance uniquely suited for industrial and technological applications where performance under extreme conditions is paramount.

The Foundation of Modern Industry: Abrasives and Machining

The most widespread use of synthetic diamonds is in industrial applications that require extreme durability. This sector leverages the material's unparalleled hardness.

Unmatched Hardness for Cutting and Grinding

Synthetic diamonds are the hardest known material, making them the ultimate abrasive for cutting, grinding, and polishing other hard materials. They are ground into fine powders and used in a vast range of industrial processes.

Precision in Drilling and Crushing

Tools like diamond-tipped drill bits and saw blades rely on synthetic diamonds to cut through rock, concrete, and metal with speed and precision. Their durability ensures a long tool life even under intense physical stress.

The Industrial Workhorse

The consistency and availability of synthetic diamonds have made them indispensable. It is estimated that 98% of all industrial-grade diamond demand is now met by synthetic production.

Enabling High-Performance Electronics and Optics

In technology, heat is often the primary limiting factor for performance. Synthetic diamonds offer an elegant solution due to their unique thermal and optical properties.

The Ultimate Heat Sink

Synthetic diamonds possess the highest thermal conductivity of any material. They are used as heat sinks to rapidly draw damaging heat away from sensitive electronic components like high-power transistors, microprocessors, and laser diodes.

Transparent Windows for Extreme Energy

Because of their unique combination of thermal stability and high optical transparency across a wide spectrum, synthetic diamonds are used as protective windows. They are essential in high-power CO2 lasers and gyrotrons, allowing energy to pass through without degrading the window itself.

The Future of Semiconductors

Researchers are developing synthetic diamond-based semiconductors for next-generation electronics. Their properties are ideal for creating high-power switches and high-frequency transistors that can operate in conditions far beyond the limits of silicon.

The Frontier of Science and Technology

The purity and perfect crystal structure that can be achieved in synthetic diamonds make them a platform for fundamental scientific research and emerging technologies.

Detecting the Invisible

Specially engineered synthetic diamonds are used as radiation and particle detectors in high-energy physics research facilities, like those at CERN. Their stability and sensitivity allow for precise measurements of subatomic particles.

Building Blocks for Quantum Computing

The crystal lattice of a synthetic diamond can be used to hold and isolate individual atoms. This property makes it a promising material for creating qubits, the fundamental building blocks of quantum computers.

Tools for Extreme Pressure Research

The incredible strength of synthetic diamonds makes them the material of choice for high-pressure anvils. These devices are used in laboratories to simulate the extreme pressures found deep within planets, advancing our understanding of geology and material science.

Understanding the Key Distinction: Engineered vs. Natural

A common misconception is that "synthetic" implies "inferior." For industrial and scientific applications, the opposite is often true.

The Myth of Inferiority

Synthetic diamonds are not fakes; they are grown in highly controlled laboratory environments. This process allows for the creation of diamonds with specific properties tailored to a particular application, such as enhanced hardness or thermal conductivity.

Purity by Design

Natural diamonds almost always contain impurities, most commonly nitrogen, which alters their properties. Synthetic manufacturing can produce exceptionally pure diamonds (like Type IIa) that are chemically and structurally perfect, a necessity for advanced optical and electronic uses.

Performance Over Origin

For technological applications, the origin of the diamond is irrelevant. What matters are measurable properties: hardness, thermal conductivity, chemical stability, and optical transparency. In these metrics, engineered diamonds consistently meet and often exceed the specifications of their natural counterparts.

How to Contextualize Synthetic Diamond Applications

To grasp their importance, it's best to categorize their use by the problem they solve.

- If your primary focus is heavy industry and manufacturing: Recognize synthetic diamonds as the backbone of modern machining, providing the non-negotiable hardness required for cutting, grinding, and drilling.

- If your primary focus is advanced electronics and thermal management: View them as a critical enabling material for dissipating heat, pushing the performance limits of high-power processors, lasers, and transistors.

- If your primary focus is scientific research and future technology: Understand them as a unique platform material, whose perfect, controllable structure is essential for applications from quantum computing to high-energy particle detection.

Ultimately, the diverse applications of synthetic diamonds demonstrate our growing ability to engineer materials that can outperform nature to solve critical technological challenges.

Summary Table:

| Application Category | Key Use Cases | Key Diamond Property Utilized |

|---|---|---|

| Industrial Machining | Cutting, Grinding, Drilling, Polishing | Extreme Hardness & Durability |

| Electronics & Optics | Heat Sinks, Laser Windows, Semiconductors | Highest Thermal Conductivity & Optical Transparency |

| Scientific Research | Radiation Detectors, Quantum Qubits, High-Pressure Anvils | Purity, Perfect Crystal Structure & Stability |

Unlock the potential of engineered materials in your lab. Synthetic diamonds are the pinnacle of material science, offering unparalleled performance for demanding applications. KINTEK specializes in providing high-quality lab equipment and consumables, including advanced materials like synthetic diamonds, to power your research and industrial processes. Contact our experts today to discuss how our solutions can enhance your project's precision, efficiency, and thermal management.

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- CVD Diamond Domes for Industrial and Scientific Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Optical Windows for Lab Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- How do laboratory shakers or stirrers ensure coating quality? Achieve Uniform Sol-Gel Nanocoatings with Precision

- What is the temperature of sintering process? A Guide to Optimizing Your Thermal Treatment

- What is sputtering method? A Guide to Advanced Thin-Film Coating Technology

- What metals can you braze together? A Guide to Strong, Versatile Metal Joining

- What would be an advantage of biomass over the use of coal? A Cleaner, Carbon-Neutral Energy Source

- What are the advantages of using titanium? Achieve Unmatched Strength and Corrosion Resistance

- Why is it necessary to mix metal powders and diamond particles? Achieve Homogeneity for Superior Tool Performance

- How do you remove solvent by evaporation? Master the Techniques for Safe and Efficient Sample Preparation