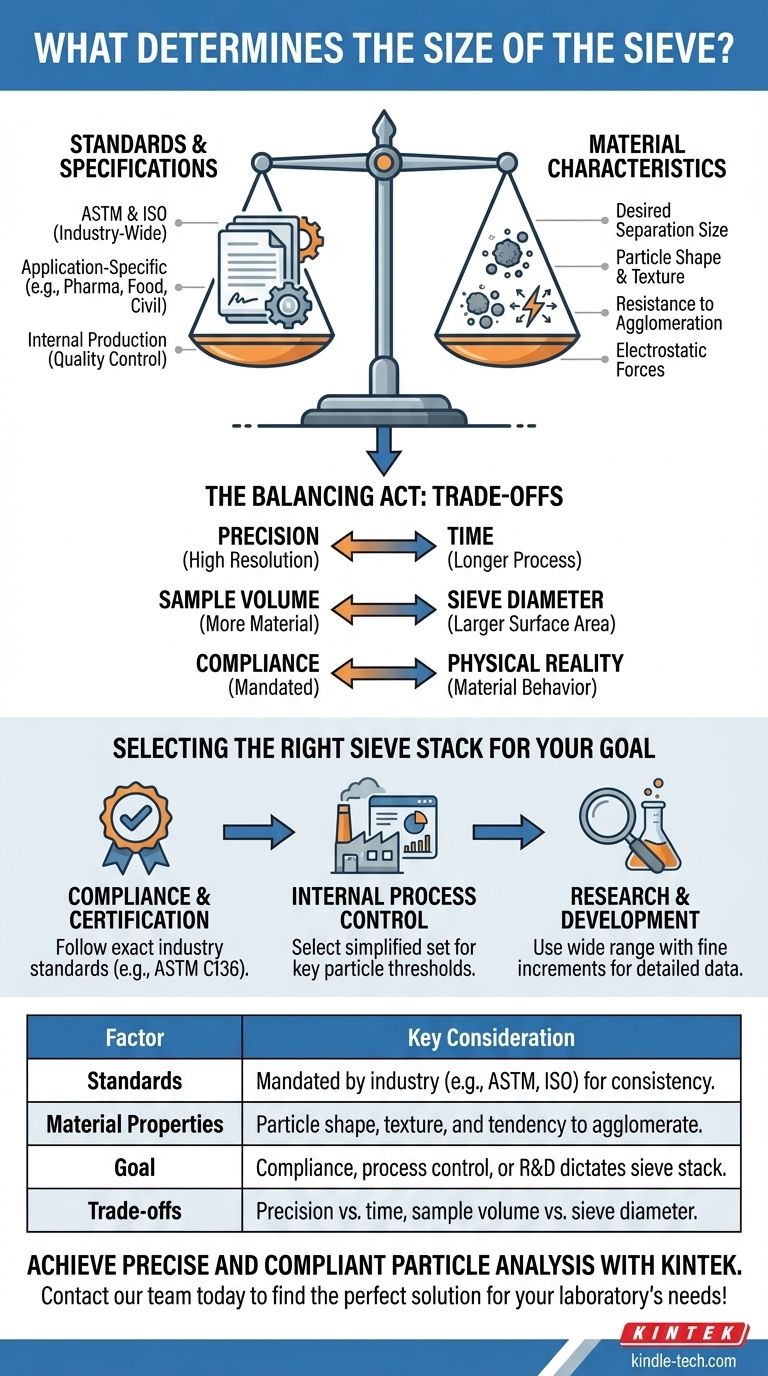

In short, the size of the sieve you use is determined by two main forces: the external requirements of your industry and the internal properties of the material you are analyzing. Industry or application-specific standards often dictate a precise set of sieve mesh sizes to ensure results are consistent and comparable, while the physical characteristics of your sample dictate what is practical and effective for achieving accurate separation.

Choosing the right sieve isn't just about picking a mesh size; it's about designing a valid test. The goal is to strike a precise balance between adhering to mandated standards and accounting for the unique physical nature of your material to ensure your results are both compliant and scientifically sound.

The Role of Standards and Specifications

The most significant factor in sieve selection is often the set of rules you are required to follow. These standards remove ambiguity and ensure that results from different facilities or at different times can be reliably compared.

Industry-Wide Standards (ASTM & ISO)

Governing bodies like ASTM International and the International Organization for Standardization (ISO) publish standardized test methods that specify exact sieve series. For example, the U.S. Standard Sieve Series (ASTM E11) provides a fixed set of mesh sizes with a consistent progression, forming the basis for countless material testing protocols across geology, construction, and manufacturing.

Application-Specific Requirements

Beyond general standards, specific industries have their own requirements. The pharmaceutical industry, for instance, has strict guidelines on powder granularity to ensure proper dosage and dissolution rates. Likewise, the food industry uses specific sieves to control the texture of products like flour and spices, and civil engineering relies heavily on sieving to grade aggregates for concrete and asphalt.

Internal Production Standards

A company may also establish its own internal quality standards for a proprietary product. These standards define an acceptable particle size distribution, which is then verified by production teams using a specific, pre-determined stack of sieves.

The Influence of Material Characteristics

Even with a standard in place, the physical reality of your material plays a critical role. The effectiveness of any sieving operation is entirely dependent on how the particles interact with the mesh.

Desired Separation Size

Fundamentally, you choose sieves that bracket the particle sizes you need to measure. If your goal is to determine the percentage of particles smaller than 1 mm, a 1 mm sieve is a necessary component of your test.

Particle Shape and Texture

The shape of a particle dramatically affects its ability to pass through a sieve opening. Long, needle-like particles or flat, flaky ones may not pass through a mesh opening that a spherical particle of a similar mass would easily clear. This can impact the required sieving time and agitation method.

Resistance to Agglomeration

Materials that are moist, oily, or naturally cohesive tend to clump together, a phenomenon known as agglomeration. These clumps will not pass through the mesh correctly, leading to inaccurate results. This characteristic might necessitate sample pre-treatment (like drying) or a more aggressive sieving action.

Electrostatic Forces

Fine, dry powders are especially prone to developing a static charge during handling and sieving. This causes particles to cling to the sieve mesh and frame instead of passing through, which can significantly skew the final analysis.

Understanding the Trade-offs

Selecting a sieve stack is an exercise in balancing competing priorities. Understanding the inherent trade-offs is key to developing a practical and effective testing procedure.

Precision vs. Time

Using a large number of sieves with very small increments between sizes will yield a high-resolution particle size distribution. However, this process is also significantly more time-consuming. Conversely, using only a few key sieves is fast but provides a much coarser, lower-resolution view of the material.

Sample Volume vs. Sieve Diameter

The amount of material you need to test directly influences the required sieve diameter. Overloading a small-diameter sieve with too much sample will "blind" the mesh, preventing particles from passing through and rendering the test invalid. A larger sieve diameter provides more surface area, allowing a larger volume of material to be processed effectively.

Compliance vs. Physical Reality

Occasionally, a material's properties (like heavy agglomeration) may make it difficult to meet a testing standard. This mismatch is a critical finding in itself. It signals that either the testing method needs adjustment (e.g., adding a de-agglomerating agent) or, more often, that the material itself is out of specification.

Selecting the Right Sieve Stack for Your Goal

Your specific objective should guide your final selection. Consider your primary goal to zero in on the best approach.

- If your primary focus is regulatory compliance or certification: Start by identifying the exact industry standard (e.g., ASTM C136 for aggregates) and procure the precise sieve sizes it mandates.

- If your primary focus is internal process control: Define the critical particle size thresholds that impact your product's quality and select a simplified set of sieves that bracket these key values for rapid testing.

- If your primary focus is research and development: Use a wide range of sieves with fine increments to gain a detailed, high-resolution understanding of the material's particle size distribution.

Ultimately, a well-chosen sieve stack provides a reliable, numerical language to describe and control the physical properties of your material.

Summary Table:

| Factor | Key Consideration |

|---|---|

| Standards | Mandated by industry (e.g., ASTM, ISO) for consistency. |

| Material Properties | Particle shape, texture, and tendency to agglomerate. |

| Goal | Compliance, process control, or R&D dictates sieve stack. |

| Trade-offs | Precision vs. time, sample volume vs. sieve diameter. |

Achieve precise and compliant particle analysis with the right sieves from KINTEK.

Whether you're working in pharmaceuticals, construction, food processing, or R&D, selecting the correct sieve stack is critical for accurate results. KINTEK specializes in high-quality lab equipment, including a full range of test sieves that meet ASTM and ISO standards.

Our experts can help you:

- Identify the exact sieves required for your industry's standards.

- Optimize your sieving process for materials with challenging properties like static or agglomeration.

- Improve your lab's efficiency with reliable equipment designed for accurate particle size distribution analysis.

Don't let sieve selection slow down your quality control or research. Contact our team today to find the perfect solution for your laboratory's needs!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

People Also Ask

- What is the primary function of fine-mesh test sieves? Master Natural Mordenite Purification

- What is the diameter of a test sieves? A Guide to Choosing the Right Size for Your Lab

- Why is the use of standard sieving systems necessary for corn stover? Maximize Lignin Degradation with KINTEK

- What are the limitations of sieving? Understanding the Constraints of Particle Size Analysis

- What is the significance of using precision standard sieves for Inconel 625/TiB2? Optimize DLD Powder Quality

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- Why is it necessary to use a laboratory sieve after the synthesis and calcination of a photocatalyst? Ensure Accuracy

- What is the difference between wet and dry sieve analysis? Choose the Right Method for Accurate Particle Sizing