The fundamental difference between Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) lies in how the coating material arrives at the substrate. CVD uses a chemical reaction, where precursor gases decompose on a heated surface to form a new solid film. In contrast, PVD is a physical process that vaporizes a solid or liquid source material and transfers it onto a substrate in a vacuum.

At its core, the choice between CVD and PVD is a trade-off between process and outcome. CVD offers superior coating conformity and adhesion through chemical bonding but is limited by high temperatures. PVD operates at lower temperatures, making it more versatile, but its physical, line-of-sight nature can result in less uniform coatings and weaker bonds.

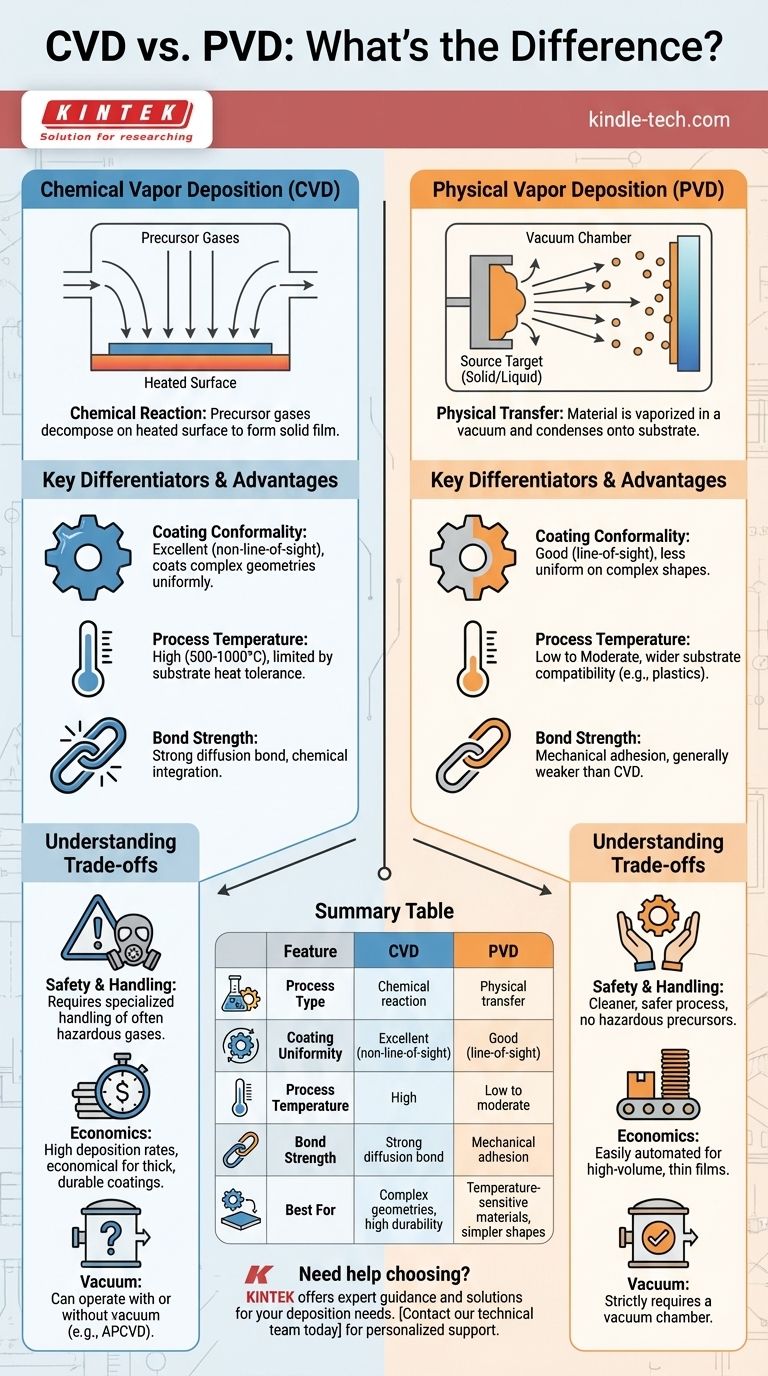

The Core Mechanism: Chemical Reaction vs. Physical Transfer

The defining characteristic of each process dictates its advantages, limitations, and ideal applications. Understanding this core difference is the key to selecting the right method.

How CVD Works: Building a Film from Gas

In CVD, volatile precursor gases are introduced into a reaction chamber containing the substrate.

The substrate is heated, providing the energy needed to trigger a chemical reaction. The gases decompose and react on the hot surface, "building" a thin film atom by atom.

This chemical process creates a strong, diffusion-type bond as the coating material integrates with the substrate's surface layer.

How PVD Works: Transferring Solid to Film

PVD is a mechanical transfer process that occurs under a vacuum.

A solid source material (the "target") is vaporized through methods like heating (evaporation) or bombardment with ions (sputtering).

These vaporized particles then travel in a straight line through the vacuum chamber and condense onto the cooler substrate, forming the coating.

Key Differentiators in Application

The difference in mechanism leads to significant practical distinctions in how these coatings are applied and what they can achieve.

Coating Conformality: The Line-of-Sight Problem

PVD is a line-of-sight process. Because the vaporized particles travel in straight lines, any area not directly exposed to the source will receive little or no coating. This can result in uneven layers on complex shapes.

CVD is not a line-of-sight process. The precursor gases flow and envelop the entire substrate, reacting on all exposed surfaces. This gives CVD high "throwing power," allowing it to produce highly uniform coatings on intricate geometries, deep recesses, and even inside holes.

Process Temperature: The Deciding Factor for Substrates

CVD typically requires very high temperatures to initiate the necessary chemical reactions on the substrate's surface. This limits its use to materials that can withstand this heat without deforming or being damaged.

PVD generally operates at lower temperatures. Because it does not rely on a chemical reaction at the substrate, it is suitable for coating a much wider range of materials, including temperature-sensitive plastics, alloys, and composites.

An exception is Plasma-Assisted CVD (PACVD), which uses plasma to generate reactive gas molecules, allowing the process to occur at much lower temperatures and expanding its substrate compatibility.

Understanding the Practical Trade-offs

Beyond the core science, several operational factors influence the choice between CVD and PVD.

Adhesion and Bond Strength

CVD's chemical reaction creates a diffused, covalent bond between the coating and the substrate, which is typically much stronger and more durable than the bond created by PVD. PVD coatings adhere more mechanically.

Safety and Material Handling

CVD often involves volatile, toxic, or corrosive precursor gases that require specialized handling and safety protocols. PVD is generally considered a cleaner, safer process as it does not rely on these hazardous chemical precursors.

Economics and Deposition Rate

CVD can often achieve very high deposition rates, making it more economical for producing thick, durable coatings. PVD, on the other hand, can be more easily automated for high-volume production of thinner films.

Vacuum Requirements

While both can operate under vacuum, PVD strictly requires a vacuum chamber for the physical transfer of material to occur. Some CVD processes, like Atmospheric Pressure CVD (APCVD), do not require a vacuum at all, which can simplify the equipment.

Making the Right Choice for Your Application

Selecting the correct process requires aligning its inherent characteristics with your primary goal.

- If your primary focus is coating complex geometries uniformly: CVD is the superior choice due to its non-line-of-sight nature.

- If your primary focus is coating temperature-sensitive substrates: PVD is the necessary choice to avoid heat damage to the underlying material.

- If your primary focus is achieving maximum coating adhesion and durability: CVD's diffusion bond provides a distinct advantage.

- If your primary focus is process simplicity and operator safety: PVD avoids the hazardous precursor chemicals common in many CVD processes.

Understanding these fundamental principles empowers you to select the deposition technology that best serves your material, geometry, and performance requirements.

Summary Table:

| Feature | CVD (Chemical Vapor Deposition) | PVD (Physical Vapor Deposition) |

|---|---|---|

| Process Type | Chemical reaction | Physical transfer |

| Coating Uniformity | Excellent (non-line-of-sight) | Good (line-of-sight) |

| Process Temperature | High (typically 500-1000°C) | Low to moderate |

| Bond Strength | Strong diffusion bond | Mechanical adhesion |

| Best For | Complex geometries, high durability | Temperature-sensitive materials, simpler shapes |

Still unsure whether CVD or PVD is right for your application?

At KINTEK, we specialize in lab equipment and consumables for all your deposition needs. Our experts can help you:

- Determine the optimal coating process for your specific substrate and geometry

- Select the right equipment for your laboratory requirements

- Ensure you achieve the coating performance and durability you need

Let us help you make the right choice for your project. Contact our technical team today for personalized guidance and solutions tailored to your laboratory's unique challenges.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the advantages of PECVD over CVD? Achieve High-Quality Thin Films at Lower Temperatures

- How plasma is generated in PECVD? A Step-by-Step Breakdown of the Process

- Why is PECVD better than CVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process