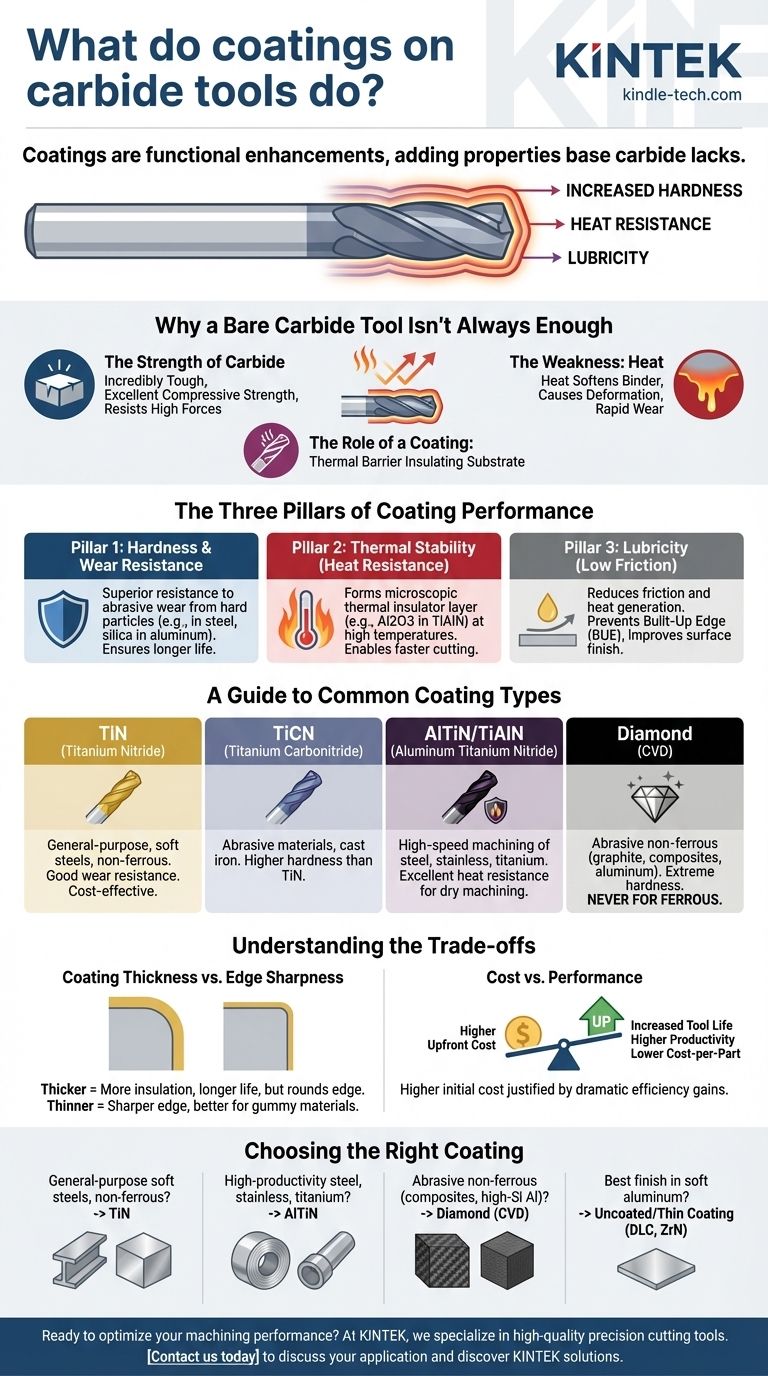

In short, coatings add critical properties that the base carbide material lacks. They act as a functional enhancement, providing increased hardness, heat resistance, and lubricity. This allows the tool to cut faster, last significantly longer, and produce better-finished parts by overcoming the limitations of the carbide substrate itself.

The core purpose of a coating is not just to protect the tool, but to fundamentally change its performance characteristics. It's a thermal and chemical barrier that allows a tough carbide body to succeed in the extreme heat and friction of modern high-speed machining.

Why a Bare Carbide Tool Isn't Always Enough

To understand coatings, we must first appreciate the material they cover. Tungsten carbide is an exceptional tool material, but it has its limits.

The Strength of Carbide

Cemented carbide is incredibly tough and has excellent compressive strength. This means it can withstand the high forces and vibrations of cutting metal without chipping or fracturing easily.

The Weakness: Heat

Carbide's primary enemy is heat. At the high speeds required for productive machining, the friction between the tool and workpiece generates immense temperatures. This heat softens the cobalt binder in the carbide, causing the cutting edge to deform and wear out rapidly.

The Role of a Coating

A coating acts as a thermal barrier, insulating the carbide substrate from the intense heat of the cutting zone. This allows the tool to maintain its hardness at much higher temperatures, enabling faster cutting speeds and feeds, which directly translates to higher productivity.

The Three Pillars of Coating Performance

Coatings are engineered to deliver three primary benefits. The priority of each benefit depends on the specific coating and its intended application.

Pillar 1: Hardness and Wear Resistance

Coatings are typically much harder than the carbide substrate. This extreme hardness provides superior resistance to abrasive wear, which occurs when cutting materials containing hard particles, such as the carbon in steel or silica in aluminum alloys.

Pillar 2: Thermal Stability (Heat Resistance)

This is arguably the most important function. Modern coatings, like Titanium Aluminum Nitride (TiAlN), are designed to not just withstand heat, but to use it. At high temperatures, they form a microscopic layer of aluminum oxide (similar to ceramics) that is an exceptional thermal insulator, protecting the carbide underneath.

Pillar 3: Lubricity (Low Friction)

A coating provides a smoother, more lubricious surface than bare carbide. This reduces friction between the tool and the workpiece chip. Less friction means less heat is generated, and it helps prevent "built-up edge" (BUE), where workpiece material welds itself to the tool, ruining the surface finish and leading to tool failure.

A Guide to Common Coating Types

While there are hundreds of specialized coatings, a few dominate the industry. Choosing the right one is based entirely on the material you are cutting.

TiN (Titanium Nitride)

This is the classic, gold-colored coating. While older, it remains a good general-purpose choice, especially for drilling and milling non-ferrous materials and basic steels. Its bright color also makes it very easy to see when the cutting edge has worn through.

TiCN (Titanium Carbonitride)

This bluish-gray or purple coating is harder and more wear-resistant than TiN. It is an excellent choice for abrasive materials and cast iron, or when higher wear resistance is needed at moderate speeds. It is less thermally stable than aluminum-based coatings.

AlTiN / TiAlN (Aluminum Titanium Nitride)

These dark purple or black coatings are the workhorses of modern machining. Their ability to form an aluminum oxide layer at high heat makes them ideal for high-speed milling and dry machining of steels, stainless steels, and high-temperature alloys. The higher the aluminum content (AlTiN vs. TiAlN), the better the high-temperature performance.

Diamond (CVD)

Unmatched in hardness, a Chemical Vapor Deposition (CVD) diamond coating is reserved for the most abrasive, non-ferrous materials. This includes graphite, carbon fiber composites (CFRP), fiberglass, and high-silicon aluminum. Never use a diamond-coated tool on steel or other ferrous materials, as the high heat will cause a chemical reaction that destroys the coating and tool.

Understanding the Trade-offs

Coatings are a performance multiplier, but they come with nuances that you must understand to use them effectively.

Coating Thickness vs. Edge Sharpness

A thicker coating provides more insulation and longer wear life. However, it also slightly rounds the cutting edge. For gummy materials like aluminum that require a razor-sharp edge to prevent BUE, a very thin, lubricious coating or even an uncoated, polished tool is often superior.

Cost vs. Performance

Coated tools have a higher upfront cost than uncoated tools. However, this cost is almost always justified by a dramatic increase in tool life and the ability to run at much higher speeds and feeds. This results in a lower cost-per-part, which is the ultimate measure of manufacturing efficiency.

Coating Adhesion

The bond between the coating and the carbide is critical. A poorly prepared tool will result in the coating flaking or chipping off, rendering it useless. Reputable manufacturers use advanced edge preparation and cleaning techniques to ensure the coating adheres perfectly.

Choosing the Right Coating for Your Application

Use the workpiece material as your primary guide.

- If your primary focus is general-purpose machining of soft steels and non-ferrous materials: A TiN-coated tool is a reliable and cost-effective choice.

- If your primary focus is high-productivity machining of steel, stainless steel, or titanium: An AlTiN or similar aluminum-based coating is the industry standard.

- If your primary focus is machining abrasive non-ferrous materials like composites or high-silicon aluminum: A diamond (CVD) coating is essential for acceptable tool life.

- If your primary focus is achieving the best possible finish in soft aluminum: An uncoated, highly polished tool or one with a very thin, slippery coating (like DLC or ZrN) will often provide the best results.

A coating elevates a cutting tool from a simple piece of carbide into a highly engineered solution for a specific machining challenge.

Summary Table:

| Coating Type | Color | Best For | Key Benefit |

|---|---|---|---|

| TiN (Titanium Nitride) | Gold | General-purpose, soft steels, non-ferrous | Good wear resistance, cost-effective |

| TiCN (Titanium Carbonitride) | Bluish-gray/Purple | Abrasive materials, cast iron | Higher hardness than TiN |

| AlTiN/TiAlN (Aluminum Titanium Nitride) | Dark purple/Black | High-speed machining of steel, stainless, titanium | Excellent heat resistance for dry machining |

| Diamond (CVD) | Gray/Black | Abrasive non-ferrous (graphite, composites, aluminum) | Extreme hardness, best for abrasion |

Ready to optimize your machining performance with the right coated carbide tools? At KINTEK, we specialize in high-quality lab equipment and consumables, including precision cutting tools designed for your specific laboratory and manufacturing needs. Our experts can help you select the ideal coating to maximize tool life, increase productivity, and improve part quality. Contact us today to discuss your application and discover how KINTEK’s solutions can enhance your efficiency and results!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory manual slicer

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

People Also Ask

- What is the role of CVD equipment in h-BN anti-corrosion coatings? Engineering Atomic-Level Metal Protection

- Which method is most suitable to synthesize single layer graphene? Master CVD for High-Quality Production

- What environmental conditions does a CVD reaction chamber provide? Optimize Coating Precision at 1050°C

- What are the typical operating parameters for RF sputtering? Optimize Your Thin Film Deposition Performance

- Why is a high-precision vacuum pump system essential for iCVD? Achieve Superior Film Purity and Uniformity

- What is the temperature of a CVD furnace? From 200°C to 1600°C for Precise Film Deposition

- What is deposition in the semiconductor industry? The Foundational Process for Building Microchips

- What is the process of MOCVD? A Step-by-Step Guide to Thin Film Deposition