At its core, a tablet punching machine consists of a coordinated system of components designed to transform a powder or granulated mixture into a solid tablet. The primary parts include a hopper to hold the material, a die to shape the tablet, a set of punches to apply pressure, a dosing system to ensure accurate weight, and an ejection mechanism to remove the finished product.

Understanding the individual parts of a tablet press is only half the story. The true insight lies in seeing how these components work together in a precise mechanical sequence to control the three critical stages of tablet manufacturing: filling, compression, and ejection.

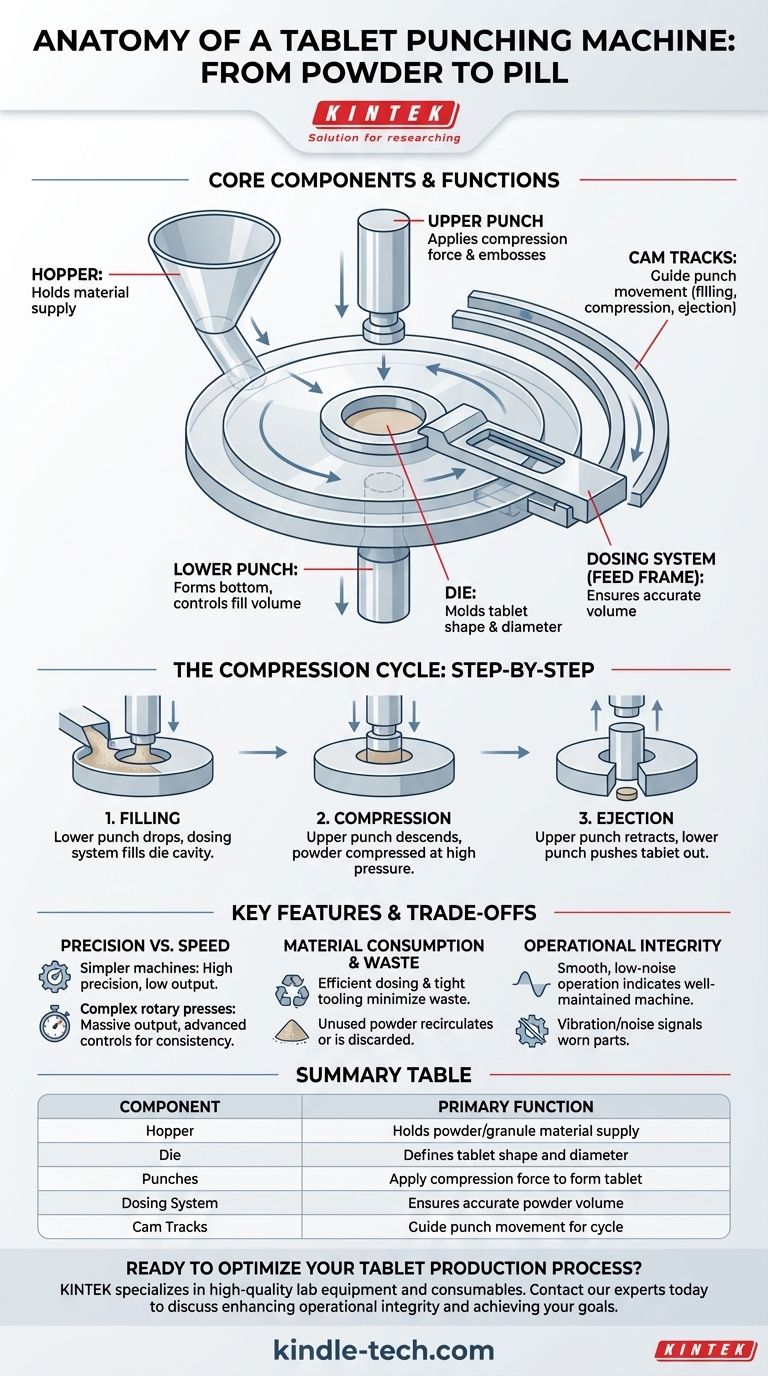

The Core Components and Their Functions

To grasp how a tablet is formed, you must first understand the role of each key component in the process.

The Hopper: The Starting Point

The hopper is a large, funnel-shaped container located at the top of the machine. Its sole purpose is to hold the powdered or granulated material before it enters the compression cycle, ensuring a continuous supply.

The Die: The Tablet's Mold

The die is the cavity that defines the final shape and diameter of the tablet. The powder mixture falls into this cavity before being compressed. The precision and finish of the die are critical for producing a tablet with a smooth surface and uniform size.

The Punches: Applying the Force

Every die is paired with two punches: an upper punch and a lower punch.

The lower punch forms the bottom of the die cavity. By adjusting its height, the machine controls the volume of powder that fills the die, which in turn determines the tablet's weight.

The upper punch descends into the die to apply the immense force required to compress the powder into a solid tablet. The shape of the punch tips can also be used to emboss logos or scoring lines onto the tablet surface.

The Dosing System: Ensuring Accuracy

Referred to as a feed frame or dosing plow, this system is responsible for moving the powder from the hopper into the die cavity. It slides over the die table, pushing a precise amount of material into the die, which is crucial for achieving high precision and tablet weight consistency.

Cam Tracks: The Mechanical Choreographer

Cam tracks are grooved paths that guide the vertical movement of the upper and lower punches. They act as the machine's brain, dictating the precise timing and sequence of the filling, compression, and ejection steps. The ejection cam, for example, specifically controls the path of the lower punch to push the finished tablet out of the die.

A Step-by-Step Look at the Compression Cycle

These components work in a rapid, synchronized cycle to produce each tablet.

Step 1: Filling

First, the lower punch drops within the die, creating a cavity of a specific volume. The dosing system then sweeps across the die table, filling this cavity with powder.

Step 2: Compression

The dosing system retracts, and the upper punch descends into the die. The powder is then compressed between the upper and lower punches at extremely high pressure, binding the particles together to form a solid tablet.

Step 3: Ejection

Finally, the upper punch retracts. The lower punch then rises, guided by the ejection cam, pushing the finished tablet up and out of the die cavity, where it is swept away for collection. This cycle repeats thousands of times per hour.

Understanding the Trade-offs and Key Features

The design of these components directly impacts the machine's performance and the quality of the final product.

Precision vs. Speed

Simpler machines, like a single punch press, offer very high precision but have a low output. Complex rotary presses have dozens of die and punch stations, allowing for massive output but requiring more sophisticated controls to maintain tablet consistency across all stations.

Material Consumption and Waste

An efficient dosing system and tightly toleranced tooling (dies and punches) are essential for minimizing material waste. Any powder that doesn't make it into the die cavity must be recirculated or discarded, reducing the overall yield.

Operational Integrity

Smooth, low-noise operation is not just an operator convenience; it is an indicator of a well-maintained machine. Excessive vibration or noise can signal worn-out cams or punches, which can lead to inconsistent tablet quality and eventual machine failure.

Making the Right Choice for Your Goal

Understanding this process allows you to focus on what matters most for your specific role.

- If your primary focus is on operation: Mastering the interaction between the dosing system, punch height, and machine speed is key to achieving consistent tablet weight and hardness.

- If your primary focus is on quality control: The condition of the dies and punches is paramount, as they directly determine the tablet's final dimensions, thickness, and appearance.

- If your primary focus is on maintenance: The cam tracks and punches are high-wear components that require regular inspection and lubrication to ensure smooth operation and prevent costly downtime.

Ultimately, viewing a tablet press as an integrated system, rather than a collection of parts, is the first step toward mastering the tablet manufacturing process.

Summary Table:

| Component | Primary Function |

|---|---|

| Hopper | Holds the powder/granule material supply |

| Die | Defines the tablet's shape and diameter |

| Punches | Apply compression force to form the tablet |

| Dosing System | Ensures accurate powder volume for consistent weight |

| Cam Tracks | Guide punch movement for the filling, compression, and ejection cycle |

Ready to optimize your tablet production process? Understanding your machine is the first step. The next is ensuring you have reliable equipment and expert support. KINTEK specializes in high-quality lab equipment and consumables for the pharmaceutical and research industries. Whether you need precision tooling like dies and punches, or are looking to upgrade your entire system for better efficiency and yield, our team is here to help.

Contact our experts today to discuss how KINTEK's solutions can enhance your operational integrity, reduce waste, and achieve your tablet manufacturing goals.

Visual Guide

Related Products

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- How does a rotary tablet press work? A Guide to High-Speed Tablet Manufacturing

- What are the advantages of press working operation? Unlock High-Speed, Low-Cost Mass Production

- What are the disadvantages of press working? High Costs and Design Limits for Mass Production

- What is the difference between single punch and rotary tablet press? Choose the Right Machine for Your Lab or Production

- How does a larger area affect the pressure of the same force? Master the Physics of Force Distribution