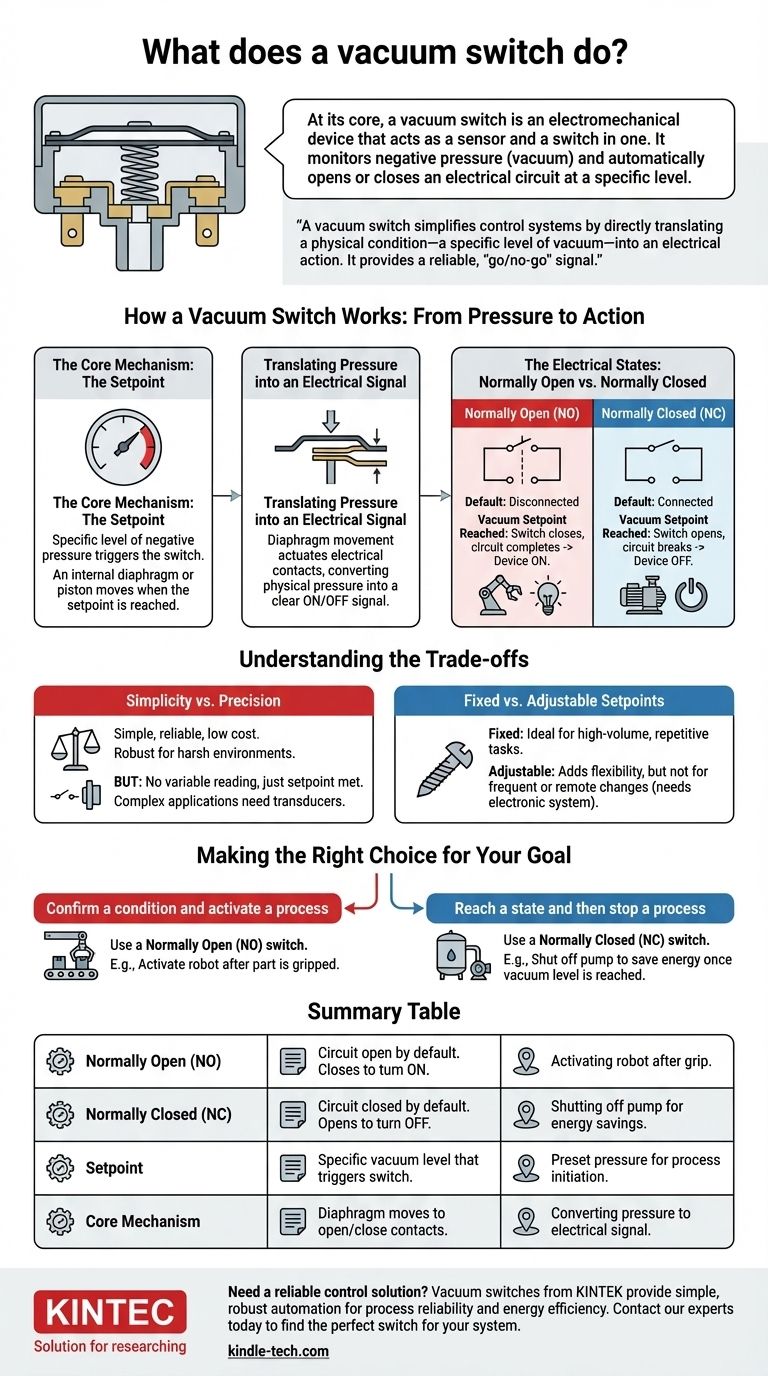

At its core, a vacuum switch is an electromechanical device that acts as a sensor and a switch in one. It monitors the level of negative pressure (vacuum) in a system and automatically opens or closes an electrical circuit when that pressure reaches a specific, predetermined level. This simple action allows it to power a device on or turn it off in direct response to a physical change.

A vacuum switch simplifies control systems by directly translating a physical condition—a specific level of vacuum—into an electrical action. It provides a reliable, "go/no-go" signal without the need for more complex electronic sensors and controllers.

How a Vacuum Switch Works: From Pressure to Action

To use a vacuum switch effectively, you must understand its three key operational concepts: the setpoint, the internal mechanism, and the electrical state.

The Core Mechanism: The Setpoint

The setpoint is the specific level of negative pressure that triggers the switch. When the vacuum in the connected system reaches this preset value, an internal diaphragm or piston moves.

Think of it like a spring-loaded latch on a door. It remains closed until you apply a specific amount of force. Similarly, the switch remains in its default state until the "force" of the vacuum is strong enough to cross the setpoint threshold.

Translating Pressure into an Electrical Signal

The movement of the internal diaphragm directly actuates a set of electrical contacts. This is the "switch" part of the "vacuum switch."

When the diaphragm moves, it either pushes two contacts together to complete a circuit or pulls them apart to break it. This is how a physical pressure change is converted into a clear electrical on/off signal.

The Electrical States: Normally Open vs. Normally Closed

The default state of the switch's electrical contacts is the most critical factor for its application.

- Normally Open (NO): In this configuration, the electrical circuit is disconnected by default. When the vacuum setpoint is reached, the switch closes the contacts and completes the circuit, turning the connected device ON.

- Normally Closed (NC): In this configuration, the electrical circuit is connected by default. When the vacuum setpoint is reached, the switch opens the contacts and breaks the circuit, turning the connected device OFF.

Understanding the Trade-offs

While highly effective, vacuum switches have specific characteristics that make them suitable for some tasks but not others.

Simplicity vs. Precision

Mechanical vacuum switches are prized for their simplicity, reliability, and low cost. They are robust and perform well in harsh industrial environments.

However, they do not provide a variable reading of the pressure level. They only report whether the setpoint has been met. For applications requiring precise, real-time pressure data, a more complex vacuum transducer or electronic sensor is necessary.

Fixed vs. Adjustable Setpoints

Many basic vacuum switches come with a factory-set, fixed setpoint. This is ideal for high-volume, repetitive applications where the target vacuum level never changes.

Other models offer an adjustable setpoint, typically configured with a screw. While this adds flexibility, they are not designed for applications where the setpoint needs to be changed frequently or remotely, which would require a fully electronic system.

Making the Right Choice for Your Goal

The choice between a Normally Open or Normally Closed switch is determined entirely by the desired default state of your system and what you want to happen when a vacuum is achieved.

- If your primary focus is to confirm a condition and activate a process: Use a Normally Open (NO) switch. This is perfect for turning on an indicator light or enabling a robot to move only after a part is securely held by a vacuum gripper.

- If your primary focus is to reach a state and then stop a process: Use a Normally Closed (NC) switch. This is ideal for energy-saving applications, like shutting off a vacuum pump once the desired vacuum level in a tank has been reached.

By correctly matching the switch's electrical state to your system's goal, you can create simple, reliable, and effective automated controls.

Summary Table:

| Feature | Description | Example Application |

|---|---|---|

| Normally Open (NO) | Circuit is open by default. Closes to turn a device ON when vacuum is achieved. | Activating a robot after a part is gripped. |

| Normally Closed (NC) | Circuit is closed by default. Opens to turn a device OFF when vacuum is achieved. | Shutting off a vacuum pump to save energy. |

| Setpoint | The specific vacuum level that triggers the switch. | A preset pressure for process initiation or safety. |

| Core Mechanism | A diaphragm or piston moves to open/close electrical contacts. | Converting physical pressure into an electrical signal. |

Need a reliable control solution for your lab or production line?

Vacuum switches from KINTEK provide the simple, robust automation you need to ensure process reliability and energy efficiency. Whether you're building vacuum gripping systems, monitoring filtration, or controlling industrial processes, our expertise in lab equipment and consumables ensures you get the right component for your application.

Contact our experts today to discuss your specific requirements and find the perfect vacuum switch for your system.

Visual Guide

Related Products

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Cold Mounting Machine for Sample Preparation

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- How does temperature affect vacuum pressure? Master the Key to System Control

- How can porosity be reduced? Achieve Maximum Material Strength and Density

- What are hot presses used for? Transforming Materials with Heat and Pressure

- What are the effects of temperature and pressure on evaporation? Mastering Control for Your Process

- How do automated precision furnaces influence Zr1Nb structural evolution? Master Hydrogenation and Polygonization