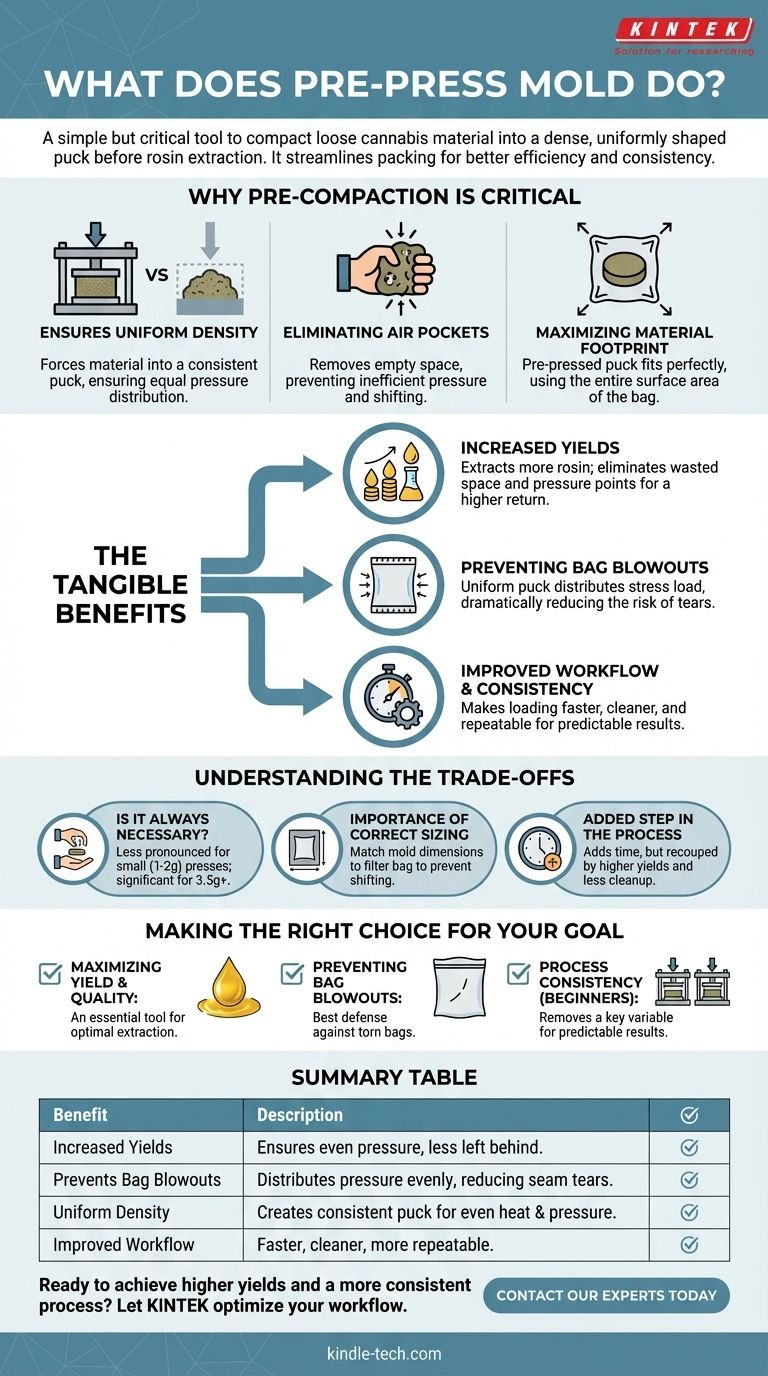

In essence, a pre-press mold is a simple but critical tool used to compact loose cannabis material into a dense, uniformly shaped puck. This is done before the material is placed into a filter bag for rosin extraction. It streamlines the packing process, making it far more efficient and consistent than packing by hand.

The core purpose of a pre-press mold is not just to pack material, but to fundamentally improve the physics of the extraction. By creating a dense, uniform puck, you ensure even pressure and heat distribution, which is the key to preventing bag blowouts and maximizing your final yield.

Why Pre-Compaction is Critical for Rosin Pressing

Simply loading loose flower or hash into a bag introduces significant variables that undermine the extraction process. A pre-press mold is designed to eliminate these variables before you ever apply heat or pressure.

Ensuring Uniform Density

When you press loose material, the pressure is not applied evenly. It will find the path of least resistance, creating high-pressure channels and leaving other areas under-utilized. A pre-press mold forces the material into a puck of consistent density, ensuring the force from the press is distributed equally across the entire surface.

Eliminating Air Pockets

Air is the enemy of an efficient press. Empty space within the filter bag acts as a buffer, absorbing initial pressure and causing the material to shift and settle unevenly as it's squished. Compacting the material into a solid puck removes these air pockets from the start.

Maximizing Material Footprint

A pre-pressed puck is sized to fit perfectly within a specific filter bag. This allows you to use the entire surface area of the bag for extraction. Loose material, by contrast, tends to form a mound in the center, leaving the corners of the bag inactive and wasted.

The Tangible Benefits of Using a Pre-Press Mold

Translating these principles into practice reveals clear, measurable advantages in your workflow and final product.

Increased Yields

By ensuring every part of your material receives optimal, even pressure, you extract more rosin. Eliminating wasted space and inefficient pressure points means less oil gets left behind in the puck, directly contributing to a higher return.

Preventing Bag Blowouts

A bag blowout is one of the most common points of failure in rosin pressing. This is almost always caused by uneven pressure creating a single, high-stress point on a bag seam, forcing it to tear. A uniform puck distributes this stress load evenly, dramatically reducing the risk of blowouts.

Improved Workflow and Consistency

Using a mold makes the process of loading bags faster, cleaner, and far more repeatable. This consistency is crucial for anyone trying to dial in their technique, as it removes a major variable from the equation, allowing for more predictable results from one press to the next.

Understanding the Trade-offs

While highly recommended, a pre-press mold is a tool with specific considerations. Understanding them ensures you use it effectively.

Is It Always Necessary?

For very small presses (1-2 grams), the benefits may be less pronounced, and careful hand-packing can suffice. However, for any quantity of 3.5 grams or more, a mold provides a significant and worthwhile advantage in yield and safety.

The Importance of Correct Sizing

A pre-press mold is not a one-size-fits-all tool. The mold's dimensions are designed to match a specific filter bag size. Using a mold that is too small for your bag will create a puck that can shift, defeating the purpose. Always match your mold to your bag size.

An Added Step in the Process

Objectively, using a mold adds an extra step to your workflow. However, the time spent pre-pressing (typically less than a minute) is easily recovered by the time saved from not having to clean up after a blowout and the value gained from higher yields.

Making the Right Choice for Your Goal

Integrating a pre-press mold into your process is a strategic decision based on your desired outcome.

- If your primary focus is maximizing yield and quality: A correctly sized pre-press mold is an essential tool, not an optional accessory.

- If your primary focus is preventing frustrating bag blowouts: The uniform puck created by a mold is your single best defense against torn bags and lost product.

- If you are a beginner looking for process consistency: Using a mold removes a key variable, helping you achieve more predictable and repeatable results as you learn.

Ultimately, this simple device elevates your control over the entire extraction process, turning a variable art into a more precise science.

Summary Table:

| Benefit | Description |

|---|---|

| Increased Yields | Ensures even pressure for optimal oil extraction, leaving less behind. |

| Prevents Bag Blowouts | Distributes pressure evenly across the bag, reducing seam tears. |

| Uniform Density | Creates a consistent puck for even heat and pressure distribution. |

| Improved Workflow | Makes loading faster, cleaner, and more repeatable than hand-packing. |

Ready to achieve higher yields and a more consistent rosin pressing process?

A pre-press mold is a simple tool that delivers significant results. At KINTEK, we specialize in precision lab equipment and consumables for extraction professionals. Let us help you optimize your workflow and maximize your return.

Contact our experts today to find the perfect pre-press mold for your needs!

Visual Guide

Related Products

- Polygon Press Mold for Lab

- Ball Press Mold for Lab

- Special Shape Press Mold for Lab

- Assemble Lab Cylindrical Press Mold

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

People Also Ask

- What are the advantages of using PEEK molds for sulfide all-solid-state batteries? High Performance and Insulation

- What are the advantages of using high-strength graphite molds in the hot press sintering of Ti6Al4V-based composites?

- What are the primary functions of graphite molds in NiCr powder metallurgy? Optimize Your Composite Material Density

- What is the core function of high-strength graphite molds? Master Vacuum Hot Press Sintering Efficiency

- Is it fitting the mould or mold? A Guide to Correct Spelling by Region