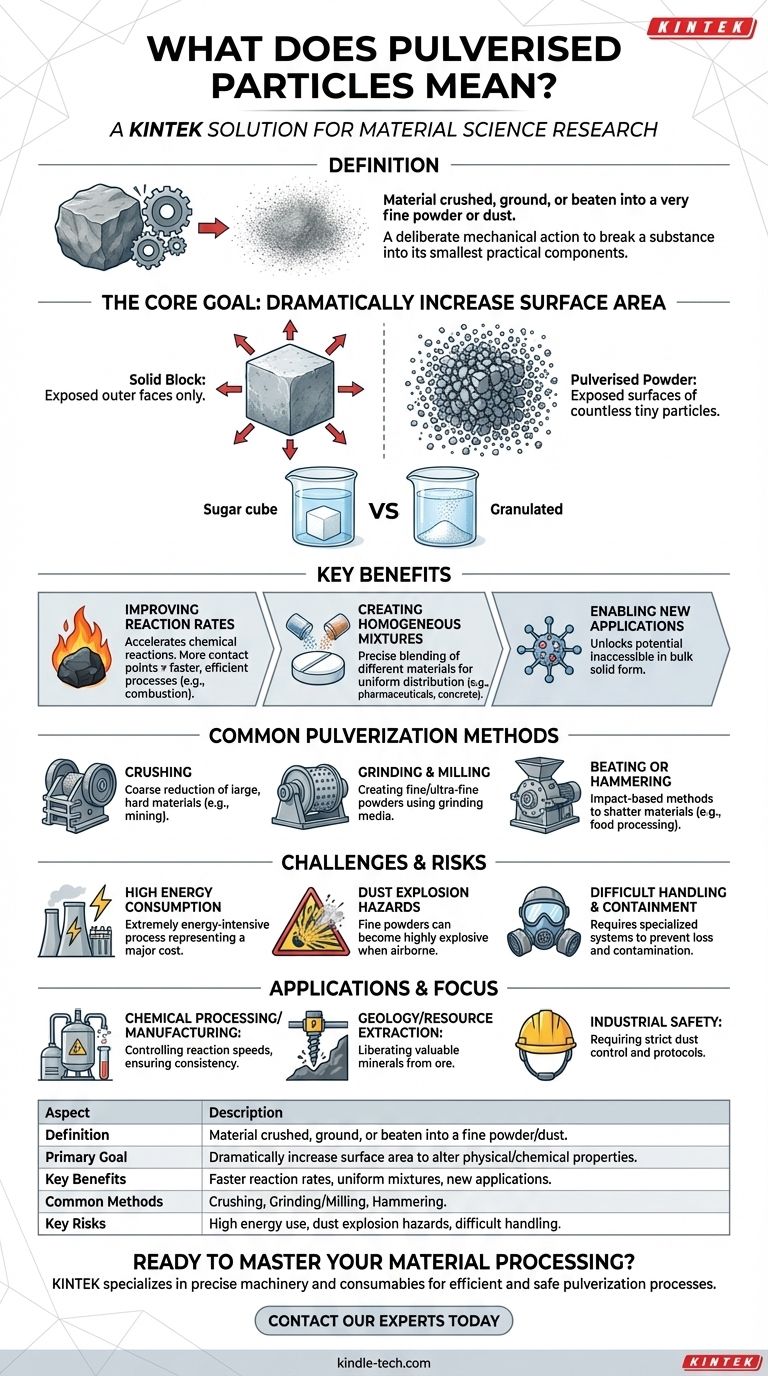

In short, pulverised particles are the result of a material being crushed, ground, or beaten into a very fine powder or dust. This process, known as pulverization, is a deliberate mechanical action designed to break a substance down into its smallest practical components, similar to atomization.

The core purpose of creating pulverised particles is to dramatically increase a material's surface area. This transformation is not simply about making something smaller; it's about fundamentally changing its physical and chemical properties to improve reaction rates, create uniform mixtures, and enable new applications.

The Goal of Pulverization: More Than Just Grinding

The decision to pulverize a material is driven by specific engineering and chemical goals. The process unlocks potential that is completely inaccessible when the material is in its bulk, solid form.

Maximizing Surface Area

A solid block of a material only exposes its outer faces to its environment. By pulverizing that same block into a fine powder, you expose the surfaces of countless tiny particles, massively increasing the total surface area available for interaction.

Think of a sugar cube versus granulated sugar. The granulated sugar dissolves much faster in tea because the water can act on the vast combined surface area of all the tiny crystals at once.

Improving Reaction Rates

This increase in surface area directly accelerates chemical reactions. More points of contact mean a faster and more efficient process.

This principle is critical in applications like power generation, where pulverized coal combusts almost instantly and completely, releasing energy far more efficiently than a burning lump of coal.

Creating Homogeneous Mixtures

Achieving a perfectly uniform mixture is nearly impossible with large, irregular chunks. Fine, pulverized powders, however, can be blended with incredible precision.

This is essential in pharmaceuticals, where a tiny amount of an active ingredient must be distributed evenly throughout a tablet, and in manufacturing concrete, where cement must mix uniformly with sand and water.

Common Pulverization Methods

The specific technique used depends on the material's hardness and the desired final particle size.

Crushing

Crushing is typically the first step, used for coarse reduction of large, hard materials. Industrial jaw crushers and cone crushers are used in mining and quarrying to break large rocks into more manageable gravel.

Grinding and Milling

For creating fine or ultra-fine powders, grinding and milling processes are used. A ball mill, for example, is a rotating drum filled with hard steel balls that tumble and grind the material down to a specific size.

Beating or Hammering

Impact-based methods, like a hammer mill, use high-speed rotating hammers to shatter and disintegrate materials. This is common in food processing for grinding grain or in recycling for breaking down materials.

Understanding the Challenges and Risks

While incredibly useful, working with pulverized particles introduces significant operational challenges and safety concerns.

High Energy Consumption

Reducing solid materials to fine powders is an extremely energy-intensive process. The machinery required consumes a vast amount of power, representing a major operational cost in industries like mining and cement production.

Dust Explosion Hazards

Many otherwise stable materials become highly explosive when pulverized and suspended in the air as a dust cloud. The high surface area allows for near-instantaneous combustion if an ignition source is present.

This is a critical safety risk in grain elevators (flour dust), coal mines (coal dust), and metalworking shops (metal powders).

Difficult Handling and Containment

Fine powders are notoriously difficult to handle. They can become airborne easily, posing respiratory risks, and require specialized containment, storage, and transportation systems to prevent loss and contamination.

How This Applies to Your Goal

Understanding the nature of pulverized particles is about recognizing their potential and their risks.

- If your primary focus is on chemical processing or manufacturing: Pulverization is your primary tool for controlling reaction speeds and ensuring the consistency of your final product.

- If your primary focus is on geology or resource extraction: This is the essential first step in liberating valuable minerals from worthless rock ore for further processing.

- If your primary focus is on industrial safety: The presence of pulverized particles is a major red flag, requiring strict protocols for dust control and the elimination of ignition sources.

Ultimately, mastering the process of pulverization is fundamental to manipulating and controlling the properties of solid matter.

Summary Table:

| Aspect | Description |

|---|---|

| Definition | Material crushed, ground, or beaten into a fine powder/dust. |

| Primary Goal | Dramatically increase surface area to alter physical/chemical properties. |

| Key Benefits | Faster reaction rates, uniform mixtures, new applications. |

| Common Methods | Crushing, Grinding/Milling, Hammering. |

| Key Risks | High energy use, dust explosion hazards, difficult handling. |

Ready to master your material processing?

Whether your goal is to accelerate chemical reactions, create perfectly uniform mixtures, or safely handle fine powders, the right lab equipment is critical. KINTEK specializes in the precise machinery and consumables needed for efficient and safe pulverization processes.

Contact our experts today to discuss how our solutions can help you unlock the full potential of your materials.

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What are the different types of grinding mills? Match the Mechanism to Your Material for Optimal Size Reduction

- Why is high-performance laboratory mixing or ball milling equipment necessary for 3D-printed perovskite detectors?

- What is the role of an agate mortar and pestle in preparing sulfur and iron oxide mixtures? Ensure Purity in Research

- What are 5 uses of hammer mill? Unlock Versatile Size Reduction for Your Industry

- What is the laboratory apparatus used for grinding? Find the Perfect Mill for Your Sample

- What is the difference between a ball mill and a tumbling mill? A Guide to Grinding Equipment Types

- What technical challenge does light ball milling address? Solve Powder Agglomeration in Mo10/Cu-Al2O3 Composites

- What is the function of laboratory mills? Achieve Precise Particle Size Control for Accurate Analysis