The performance of a ball mill is governed by a precise interplay of several key operational factors. To control the final particle size and grinding efficiency, you must adjust four primary variables: the rotational speed of the mill, the characteristics of the grinding media (the balls), the properties of the material being ground, and the volume of both the media and material inside the mill.

Optimizing a ball mill is not about maximizing a single setting, but about achieving a specific type of grinding action. The key is to balance speed, media, and load to create the ideal environment of impact and attrition for your specific material and desired outcome.

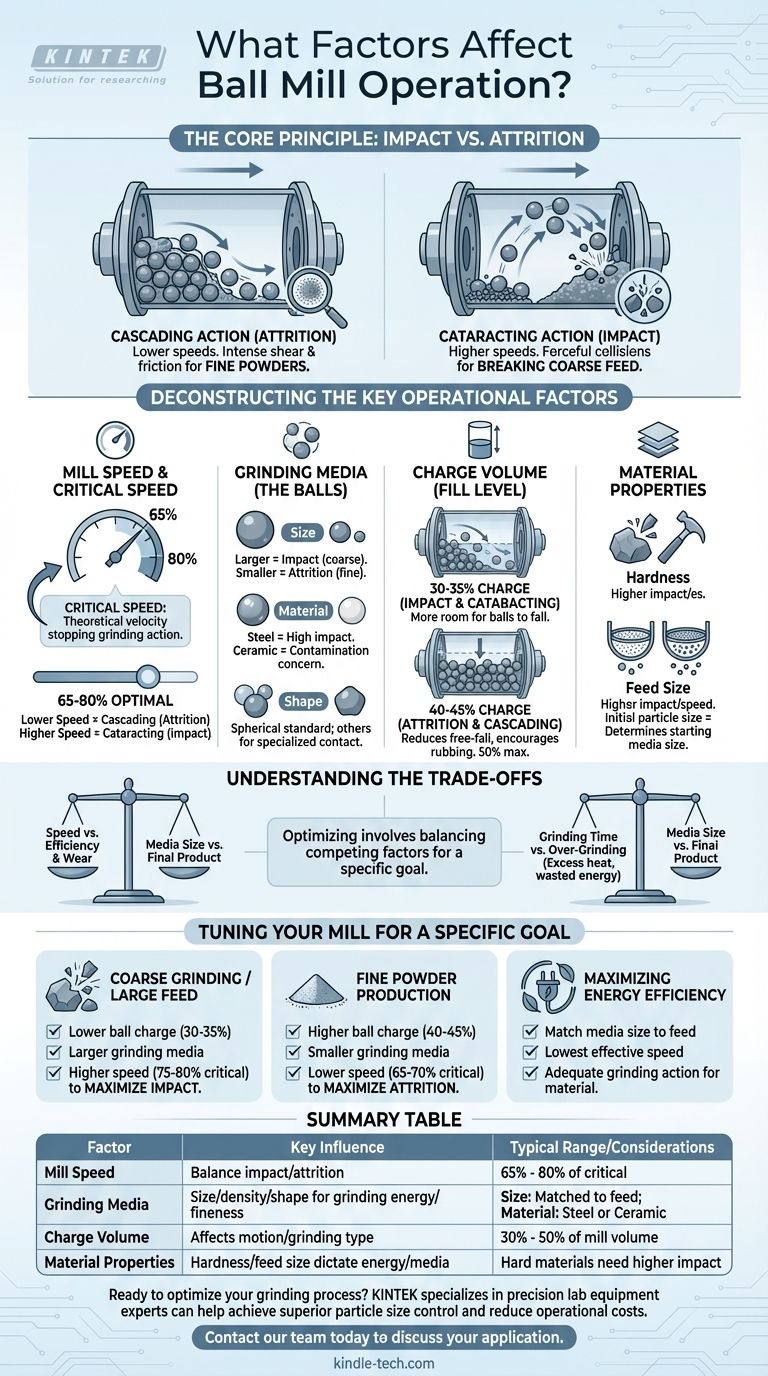

The Core Principle: Impact vs. Attrition

A ball mill reduces particle size using two fundamental actions. Your operational choices are all geared toward promoting one or a combination of both.

Cascading Action (Attrition)

At lower speeds, the grinding balls tumble down the face of the other balls in a constant, sliding motion. This creates immense shear and friction.

This "cascading" action is ideal for attrition, grinding particles very finely through rubbing. It is the preferred method for producing fine powders.

Cataracting Action (Impact)

At higher speeds, the balls are lifted higher up the mill's shell before detaching and falling onto the material below. This creates a series of forceful collisions.

This "cataracting" action emphasizes impact, which is excellent for breaking down coarser feed material quickly and efficiently.

Deconstructing the Key Operational Factors

Each operational variable directly influences the balance between cascading and cataracting within the mill.

Mill Speed and Critical Speed

The single most important factor is the mill's rotational speed, which is best understood as a percentage of its critical speed.

Critical speed is the theoretical velocity at which centrifugal force would cause the grinding media to cling to the inner wall of the mill, stopping all grinding action.

The optimal operating speed is typically between 65% and 80% of the critical speed. Speeds on the lower end of this range favor cascading (attrition), while speeds on the higher end promote cataracting (impact).

Grinding Media (The Balls)

The balls are the engine of the grinding process. Their size, material, and quantity are critical.

- Size: Larger balls create greater impact forces, ideal for breaking large feed particles. Smaller balls have a much larger total surface area, making them more efficient for fine grinding through attrition.

- Material: The density of the media affects impact energy. Steel balls are common for high-impact grinding. Ceramic balls are used when product contamination is a concern.

- Shape: While typically spherical, other shapes can be used for specialized applications to change the nature of the contact points.

Charge Volume (Fill Level)

The fill level, or charge volume, refers to the percentage of the mill's internal volume occupied by the grinding media. This is typically between 30% and 50%.

A lower ball charge (around 30-35%) provides more room for the balls to fall, promoting impact and cataracting.

A higher ball charge (around 40-45%) reduces the free-fall distance, which encourages cascading and attrition for finer grinding. Overfilling above 50% can dampen ball motion and drastically reduce efficiency.

Material Properties

The characteristics of the feed material itself will dictate your other choices. Hard materials may require higher-impact energy from larger media or higher speeds. The initial particle size of the feed dictates the appropriate starting size for the grinding media.

Understanding the Trade-offs

Optimizing a ball mill always involves balancing competing factors. There is no single "best" setting, only the best setting for a specific goal.

Speed vs. Efficiency and Wear

Higher speeds increase throughput but come at a cost. Power consumption rises significantly with speed, as does the rate of wear on both the grinding media and the mill's internal liner.

Media Size vs. Final Product

Using large media to grind material to a very fine powder is highly inefficient. The large balls lack the necessary surface area for effective attrition. Conversely, using small media to break large feed particles will be extremely slow, as the balls lack the impact energy to cause fractures.

Grinding Time vs. Over-Grinding

Simply running the mill longer is not always better. Once the target particle size is reached, further grinding generates excess heat, wastes enormous amounts of energy, and can sometimes be detrimental to the properties of the final product.

Tuning Your Mill for a Specific Goal

Use these principles to configure your operation based on your desired output.

- If your primary focus is coarse grinding or breaking down large feed: Use a lower ball charge (30-35%), larger grinding media, and operate at the higher end of the optimal speed range (75-80% of critical) to maximize impact.

- If your primary focus is producing a very fine powder: Use a higher ball charge (40-45%) with smaller grinding media and operate at lower speeds (65-70% of critical) to maximize attrition.

- If your primary focus is maximizing energy efficiency: Match the media size closely to the feed size and operate at the lowest effective speed that still provides adequate grinding action for your material.

Mastering these variables transforms ball milling from a brute-force process into a precise engineering task.

Summary Table:

| Factor | Key Influence | Typical Range/Considerations |

|---|---|---|

| Mill Speed | Balance between impact (cataracting) and attrition (cascading) | 65% - 80% of critical speed |

| Grinding Media | Size, density, and shape determine grinding energy and fineness | Size: Matched to feed; Material: Steel or Ceramic |

| Charge Volume | Affects motion of balls and type of grinding action | 30% - 50% of mill volume |

| Material Properties | Hardness and feed size dictate required energy and media choice | Hard materials need higher impact energy |

Ready to optimize your grinding process?

KINTEK specializes in precision lab equipment and consumables for laboratories. Whether you need to select the right grinding media or configure your mill for maximum efficiency, our experts can help you achieve superior particle size control and reduce operational costs.

Contact our team today to discuss your specific application and see how KINTEK solutions can enhance your results.

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- What can a ball mill produce? Achieve Fine Powders and Slurries for Your Materials

- Why are zirconia grinding beads utilized for LLZTO solid-state electrolytes? Ensuring Purity & High Ionic Conductivity

- What is the primary function of mechanical mixing equipment? Optimize C-SiC-B4C Composite Homogeneity

- What is the difference between crushing and pulverization? Design Your Efficient Size Reduction Circuit

- What is the role of a laboratory-scale ball mill in the pretreatment of microalgae biomass? Boost Cell Wall Disruption

- Why is mechanical ball milling necessary for TiAl intermetallic compounds? Optimize Your Sintering Results

- Why grinding is important in laboratory techniques? Ensure Accurate & Reproducible Results

- What is the diameter of the balls in a ball mill? Optimize Your Grinding Efficiency with the Right Size