At its core, a ball mill jar is a high-strength container designed to hold material and grinding media for processing in a ball mill. It acts as the reaction vessel where mechanical forces—impact and attrition—are applied to grind, blend, mix, or mechanically alloy solid materials. The jar is sealed, placed into the mill, and subjected to intense rotational or planetary motion to achieve the desired particle size reduction or homogenization.

The choice of a ball mill jar is not merely about finding a container that fits. It is a critical process variable that directly controls grinding efficiency, sample contamination, and the ultimate success of your materials processing goal.

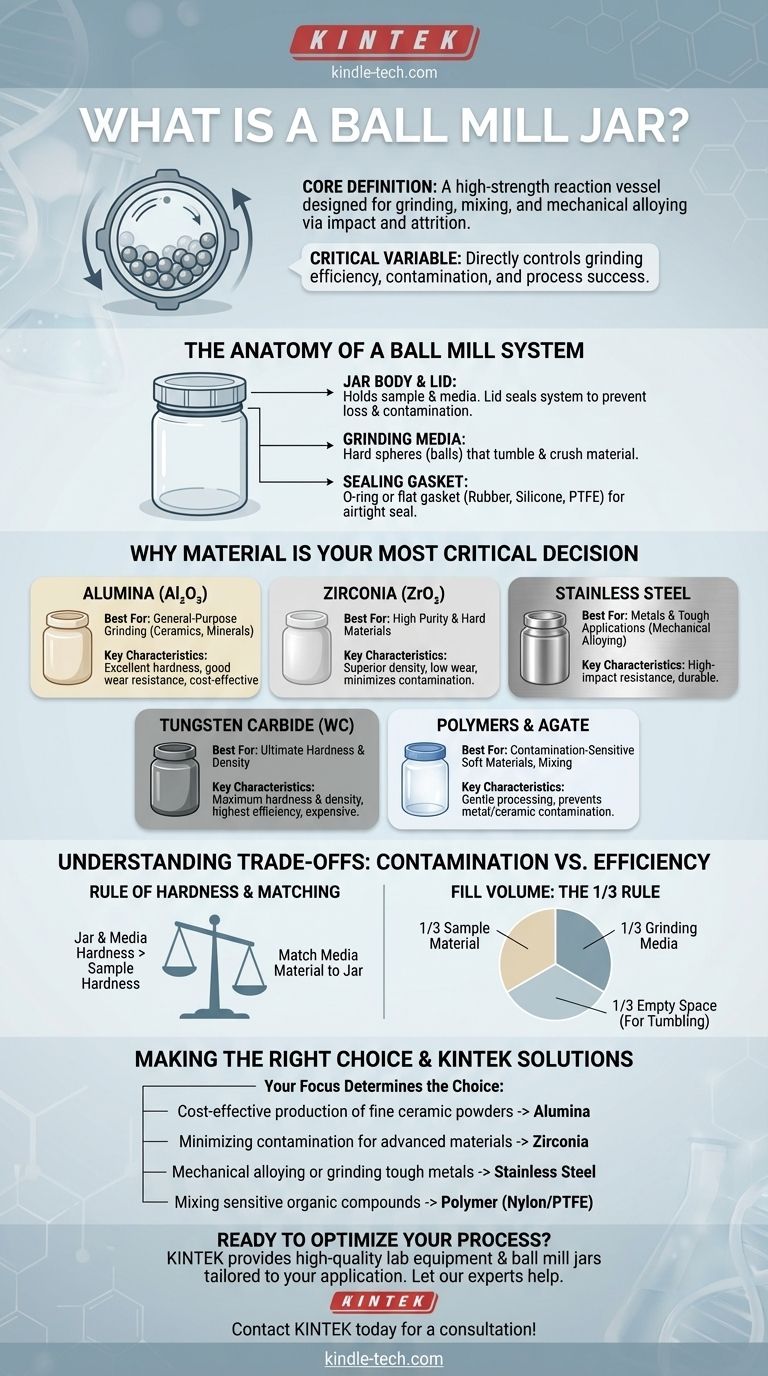

The Anatomy of a Ball Mill System

A ball mill jar is the central component of a larger system. Understanding how it interacts with other parts is key to its effective use.

The Jar Body and Lid

The main body of the jar holds the sample and grinding media. The lid, often secured with a clamp, seals the system. This prevents loss of material and protects the sample from atmospheric contamination.

The Grinding Media

Grinding media are typically spherical balls made of a very hard material. They are the primary instruments of force. As the jar rotates, the media cascade and tumble, crushing the material trapped between them.

The Sealing Gasket

An O-ring or flat gasket, usually made of rubber, silicone, or PTFE, sits between the jar and the lid. It creates an airtight seal, which is essential for wet milling (using a liquid) or when working with oxygen-sensitive materials.

Why the Jar Material is Your Most Critical Decision

The material of the jar and grinding media is the most significant choice you will make. It dictates performance and determines the type of trace contamination introduced into your sample.

For General-Purpose Grinding: Alumina

Alumina (Al₂O₃) is the workhorse of many labs. It offers excellent hardness and good wear resistance at a moderate cost. It is the default choice for grinding a wide range of ceramics, minerals, and glasses where minor alumina contamination is acceptable.

For High Purity & Hard Materials: Zirconia

Zirconia (ZrO₂) is a step up in both performance and cost. It is significantly denser and more fracture-tough than alumina, leading to more efficient grinding and much lower wear. It is ideal for applications where sample purity is paramount or when grinding very hard materials.

For Metals and Tough Applications: Stainless Steel

Stainless Steel jars are extremely tough and resistant to high-impact forces. They are the preferred choice for mechanical alloying, grinding metals, or any application where some iron (Fe), chromium (Cr), or nickel (Ni) contamination is tolerable.

For Ultimate Hardness & Density: Tungsten Carbide

Tungsten Carbide (WC) is one of the hardest and densest materials available for milling jars. It provides the highest possible grinding energy and is used for breaking down extremely hard or brittle materials with maximum efficiency. It is also the most expensive option.

For Contamination-Sensitive Soft Materials: Polymers & Agate

Jars made from Nylon, Polyurethane (PU), or PTFE are used when metal or ceramic contamination must be completely avoided. They are much softer and are primarily for mixing or gentle de-agglomeration, not aggressive grinding. Agate, a natural stone, is used in low-energy applications where silica (SiO₂) is a non-critical contaminant.

Understanding the Trade-offs: Contamination vs. Efficiency

Choosing a jar is a balancing act. The ideal choice minimizes contamination while maximizing the efficiency of your process.

The Rule of Hardness

To minimize contamination from the jar and media, they must be harder than the material you are grinding. If the sample is harder, it will abrade the jar and media, introducing significant impurities.

Matching Jar and Media Material

For optimal purity, the material of the grinding media should always match the material of the jar. Using steel balls in a zirconia jar, for example, will cause rapid wear on the balls and introduce heavy iron contamination into your sample and the zirconia jar wall.

The Fill Volume Ratio

Grinding efficiency is highest when the jar is properly filled. A common guideline is the "1/3 rule": 1/3 sample material, 1/3 grinding media, and 1/3 empty space to allow for effective tumbling and cascading motion.

Making the Right Choice for Your Application

Your specific goal determines the correct jar material.

- If your primary focus is cost-effective production of fine ceramic powders: An Alumina jar and media set is your most practical choice.

- If your primary focus is minimizing contamination for advanced materials or pharmaceuticals: A Zirconia system is the superior investment for ensuring sample purity.

- If your primary focus is mechanical alloying or grinding tough metals: A Stainless Steel jar provides the necessary durability and impact resistance.

- If your primary focus is mixing sensitive organic compounds without size reduction: A Polymer jar, such as Nylon or PTFE, will prevent unwanted contamination and sample alteration.

By treating the jar as an active and critical component in your process, you gain precise control over your material's final state.

Summary Table:

| Jar Material | Best For | Key Characteristics |

|---|---|---|

| Alumina (Al₂O₃) | General-purpose grinding (ceramics, minerals) | Excellent hardness, good wear resistance, cost-effective |

| Zirconia (ZrO₂) | High-purity applications, hard materials | Superior density, low wear, minimizes contamination |

| Stainless Steel | Mechanical alloying, tough metals | High-impact resistance, durable |

| Tungsten Carbide | Extremely hard/brittle materials | Maximum hardness and density, highest efficiency |

| Polymers (Nylon, PTFE) | Contamination-sensitive soft materials, mixing | Gentle processing, prevents metal/ceramic contamination |

Ready to optimize your grinding process? The right ball mill jar is critical for achieving your desired particle size and sample purity. At KINTEK, we specialize in providing high-quality lab equipment and consumables, including a full range of ball mill jars and grinding media tailored to your specific application—from cost-effective alumina to high-purity zirconia systems. Let our experts help you select the perfect solution to enhance your lab's efficiency and ensure contamination-free results. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Ten-Body Horizontal Jar Mill for Lab Use

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

- High Energy Planetary Ball Mill for Laboratory Horizontal Tank Type Milling Machine

- Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

People Also Ask

- What role does a horizontal ball mill play in YAG ceramic mixing? Achieve Superior Microscopic Uniformity

- How does the hardness of grinding jar and ball materials influence mechanochemistry? Optimize Your Impact Energy

- Why are agate grinding jars preferred for Li2S-P2S5 electrolytes? Ensure Purity in Solid-State Battery Research

- Why seal milling jars with argon for transition metal carbides? Ensure Purity in Mechanochemical Synthesis

- Why is a ball mill jar lined with Y-ZrO2 required for Na3PS4 synthesis? Ensuring Purity in Sulfide Electrolytes

- What is the function of a roller ball mill in Pt/C cathode slurries? Achieving Molecular-Level Homogenization

- Why use zirconia ball milling jars for SiC/ZTA composite powders? Ensure High Purity & Efficient Particle Refinement

- What is the primary function of agate grinding jars and balls in Li4Ti5O12 prep? Ensure Purity & Performance