At its core, a biochar reactor is a specialized piece of equipment designed to transform organic waste, known as biomass, into a stable, carbon-rich material called biochar. The reactor achieves this by heating the biomass to high temperatures in a low-oxygen or oxygen-free environment. This controlled process, called pyrolysis, fundamentally alters the chemical structure of the material, locking carbon into a solid form rather than releasing it into the atmosphere as carbon dioxide.

A biochar reactor is not simply an incinerator; it's a thermochemical conversion device. Instead of burning waste, it "cooks" it without oxygen to create a valuable soil amendment and sequester carbon, while also generating renewable energy as a co-product.

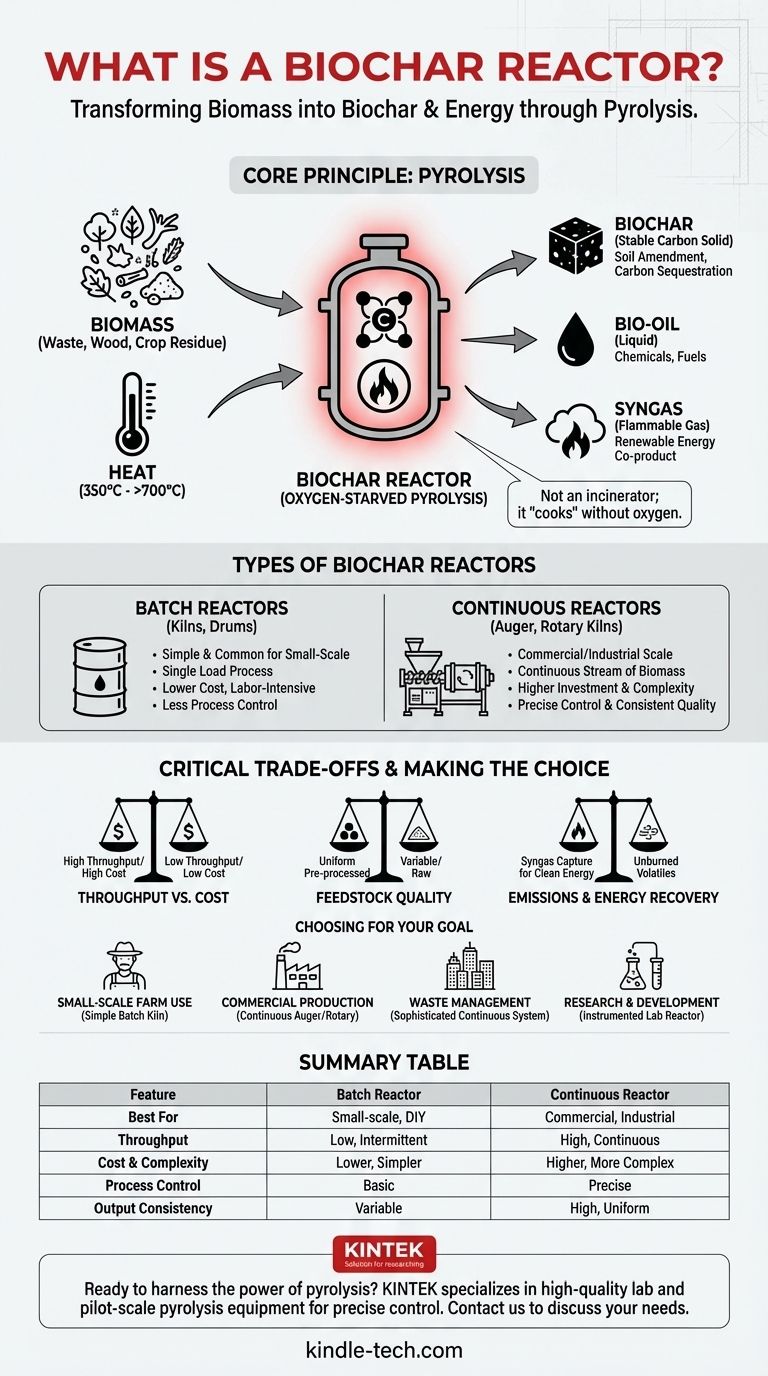

The Core Principle: How Pyrolysis Works

A biochar reactor is the vessel where the process of pyrolysis takes place. Understanding this process is key to understanding the reactor itself. Think of it as a highly controlled method of charring material, distinct from burning.

The Key Ingredients: Biomass and Heat

The process begins with biomass, which can be anything from wood chips and agricultural crop residue to manure and food waste. This feedstock is fed into the reactor, which then applies high heat, typically ranging from 350°C to over 700°C (660°F to 1300°F).

The Oxygen-Starved Environment

This is the most critical element. The reactor is sealed to prevent oxygen from entering. If oxygen were present, the biomass would simply combust (burn) and turn into ash. By starving the reaction of oxygen, we force a different chemical pathway.

The Three Products: Biochar, Bio-oil, and Syngas

Instead of just ash and smoke, pyrolysis breaks the biomass down into three distinct outputs:

- Biochar: A solid, charcoal-like material that is rich in stable carbon. This is the primary target product.

- Bio-oil (Pyrolysis Oil): A liquid mixture of various organic compounds that can be refined into chemicals or fuels.

- Syngas (Synthesis Gas): A mixture of flammable gases (like hydrogen and carbon monoxide) that can be captured and burned to provide the heat for the pyrolysis process itself, making the system more energy-efficient.

Types of Biochar Reactors

Reactors vary widely in complexity, scale, and cost, from simple DIY units to sophisticated industrial systems. They are generally categorized by how they process the biomass.

Batch Reactors (Kilns and Drums)

These are the simplest and most common types for small-scale production. Biomass is loaded in a single batch, the reactor is sealed and heated, and the resulting biochar is removed once the process is complete. They are lower cost but are labor-intensive and offer less process control.

Continuous Reactors (Auger and Rotary Kilns)

Designed for commercial or industrial-scale operations, these systems are fed a continuous stream of biomass. An auger reactor uses a large screw to move material through a heated tube, while a rotary kiln tumbles the material inside a large, heated, rotating cylinder. These offer precise control over temperature and residence time, resulting in a consistent, high-quality product.

Advanced Systems (Microwave and Hydrothermal)

More niche technologies exist, such as microwave-assisted pyrolysis, which uses microwaves for more uniform and rapid heating. Hydrothermal Carbonization (HTC) is a related process that uses hot, pressurized water to convert wet biomass into a material similar to biochar, avoiding the energy-intensive step of pre-drying the feedstock.

Understanding the Critical Trade-offs

Choosing or designing a biochar reactor involves balancing competing priorities. There is no single "best" reactor; the optimal choice depends entirely on the goal.

Throughput vs. Capital Cost

Continuous systems offer high throughput and consistent quality but require a significant upfront investment. Batch kilns are far cheaper to build or buy but produce much less biochar for the time and labor invested.

Feedstock Quality and Preparation

The "garbage in, garbage out" principle applies. The type, moisture content, and particle size of the biomass dramatically affect reactor performance and biochar quality. Continuous systems often require uniform, pre-processed feedstock, adding an extra operational step and cost.

Emissions and Energy Recovery

Simple batch kilns often release unburned volatile gases (smoke) into the atmosphere. More advanced reactors are designed to capture this syngas and combust it cleanly, either to power the process or to generate surplus energy. This dramatically improves both the environmental footprint and the overall energy balance of the operation.

Making the Right Choice for Your Goal

The right reactor is determined by your primary objective, available resources, and scale of operation.

- If your primary focus is small-scale farm use or garden soil improvement: A simple batch kiln or drum reactor offers the lowest barrier to entry for producing biochar for your own needs.

- If your primary focus is commercial biochar production and carbon sequestration: A continuous auger or rotary kiln reactor is necessary for achieving the scale, consistency, and quality demanded by the market.

- If your primary focus is sustainable waste management for a municipality or large business: A sophisticated, continuous system with robust energy recovery is the only viable path to efficiently process large waste streams.

- If your primary focus is research and development: A highly instrumented lab-scale batch or continuous reactor is required for precise control over process parameters.

Ultimately, a biochar reactor is a tool that allows us to intelligently redirect the carbon cycle to our benefit.

Summary Table:

| Feature | Batch Reactor (Kiln) | Continuous Reactor (Auger/Rotary) |

|---|---|---|

| Best For | Small-scale, DIY, farm use | Commercial, industrial-scale production |

| Throughput | Low, intermittent | High, continuous |

| Cost & Complexity | Lower cost, simpler | Higher investment, more complex |

| Process Control | Basic | Precise (temperature, residence time) |

| Output Consistency | Variable | High, uniform quality |

Ready to harness the power of pyrolysis for your operation? Whether you're a researcher developing new processes, a commercial producer scaling up, or a business seeking sustainable waste solutions, the right reactor is key to success. KINTEK specializes in high-quality lab and pilot-scale pyrolysis equipment, including robust reactors designed for precise control and reliable performance. Let our experts help you select the ideal system to transform your biomass into valuable biochar and energy.

Contact KINTEL today to discuss your specific needs and goals!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Performance Laboratory Freeze Dryer for Research and Development

- Metal Disc Electrode Electrochemical Electrode

- Cylindrical Press Mold for Lab Applications

People Also Ask

- How are laboratory high-pressure reactors utilized in RO membrane development? Enhance Desalination Research Efficiency

- What is the role of a high-pressure reactor in the synthesis of silver nanowire arrays? Enhancing Hard Template Methods

- What are the fluidized bed heating options for a pyrolysis process? Direct vs. Indirect Methods Explained

- What are the core functions of a high-pressure SHS reactor? Mastering High-Nitrogen Steel Synthesis

- How do precision reactors control product quality in Mannich amination of lignin? Achieve Superior Site-Specific Accuracy

- How do high-pressure hydrothermal reactors facilitate the synthesis of mesoporous hydroxyapatite? Precision Engineering

- What is the role of a laboratory reactor in the production of modified fly ash microspheres? Precision Surface Coating

- What is the significance of SCPW reactors for ODS steel? Evaluate Corrosion Resistance in Fusion Environments