At its core, a laboratory sieve is a precision instrument used for particle size analysis. It consists of a frame holding a wire mesh screen with openings of a specific, uniform size. By passing a material sample through one or more of these sieves, you can accurately separate particles by size and determine the material's particle size distribution.

A laboratory sieve is more than just a filter; it's a calibrated tool for a fundamental analytical process. Its purpose is to physically sort a sample into different size fractions, allowing for the quantitative measurement of a material's granular makeup.

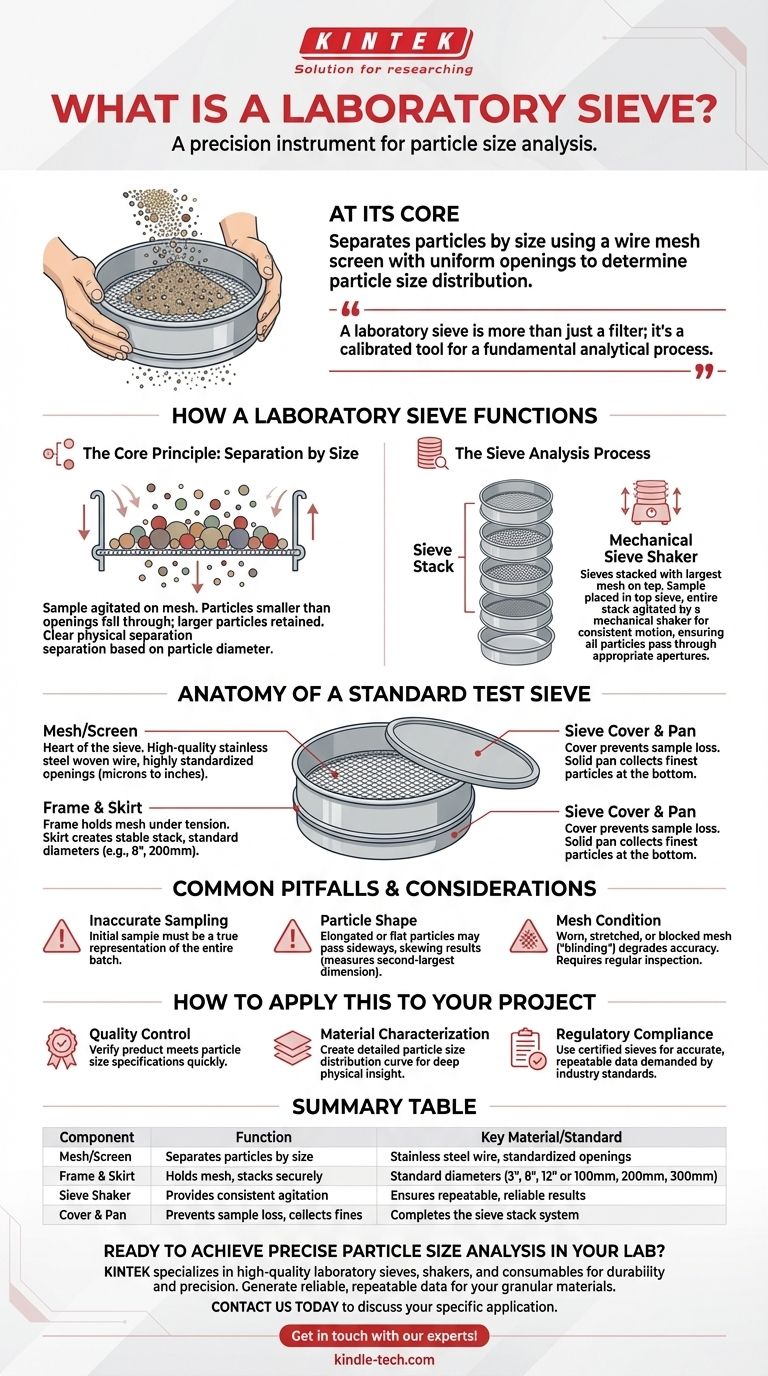

How a Laboratory Sieve Functions

The utility of a test sieve comes from its role in a standardized procedure known as a sieve analysis, which is a cornerstone of particle characterization.

The Core Principle: Separation by Size

A sieve works by a simple mechanical principle. When a sample is placed on the mesh and agitated, particles smaller than the mesh openings fall through, while particles larger than the openings are retained on top.

This process allows for a clear physical separation based on a single dimension: particle diameter.

The Sieve Analysis Process

For a full analysis, sieves are typically stacked in a column, or a "sieve stack." The sieve with the largest mesh openings is placed at the top, followed by sieves with progressively smaller openings.

A precisely weighed sample is placed in the top sieve. The entire stack is then agitated, causing the particles to travel downwards until they are retained by a mesh screen too small for them to pass through.

The Role of the Mechanical Shaker

While manual shaking is possible, a mechanical sieve shaker is standard for achieving repeatable and reliable results.

This device agitates the sieve stack with a consistent motion (such as vibrating or tapping) for a set duration, ensuring that all particles have an opportunity to pass through the appropriate apertures.

Anatomy of a Standard Test Sieve

Every component of a test sieve is designed to ensure accuracy and consistency in the separation process.

The Mesh: The Heart of the Sieve

The screen or mesh is the most critical component. It is typically made of high-quality stainless steel woven wire to resist distortion and corrosion.

Mesh opening sizes are highly standardized, ranging from several inches down to just 20 microns (635 mesh), allowing for the analysis of a vast array of materials.

The Frame and Skirt: Providing Structure

The frame is the circular metal ring that holds the mesh under tension. Common U.S. diameters are 3, 8, and 12 inches, while international standards use 100, 200, and 300 mm.

The skirt is the lower edge of the frame, designed to fit snugly onto the sieve below it, creating a stable stack that won't tip during agitation.

Sieve Covers and Pans: Completing the System

A sieve cover is placed on the top sieve to prevent loss of the sample during shaking. A solid collection pan is placed at the very bottom of the stack to collect the finest particles that pass through all screens.

Common Pitfalls and Considerations

While the process is straightforward, achieving accurate results requires an understanding of potential limitations.

Inaccurate Sampling

The initial sample must be a true representation of the entire batch of material. If the sample taken is not representative, the final analysis will not accurately reflect the bulk material's properties.

Particle Shape Can Skew Results

Sieve analysis primarily measures a particle's second-largest dimension. Elongated or flat particles may pass through openings end-on or sideways, which can lead to a misrepresentation of their true size and volume.

Mesh Condition is Critical

Over time, the wire mesh can become worn, stretched, or blocked by particles ("blinding"). This changes the effective size of the openings and degrades the accuracy of the analysis, requiring regular inspection and cleaning.

How to Apply This to Your Project

Your specific goal will determine how you approach sieve analysis.

- If your primary focus is quality control: Use a defined set of sieves to quickly verify that a product (like sand, flour, or a powdered drug) meets its required particle size specifications.

- If your primary focus is material characterization: Employ a full stack of graded sieves to create a detailed particle size distribution curve, providing deep insight into a material's physical properties.

- If your primary focus is regulatory compliance: Ensure you are using certified and calibrated test sieves to produce the accurate, repeatable data demanded by industry standards.

Ultimately, understanding the function of a laboratory sieve provides you with a powerful and direct method for analyzing the physical composition of granular materials.

Summary Table:

| Component | Function | Key Material/Standard |

|---|---|---|

| Mesh/Screen | Separates particles by size | Stainless steel wire, standardized openings |

| Frame & Skirt | Holds mesh, stacks securely | Standard diameters (3", 8", 12" or 100mm, 200mm, 300mm) |

| Sieve Shaker | Provides consistent agitation | Ensures repeatable, reliable results |

| Cover & Pan | Prevents sample loss, collects fines | Completes the sieve stack system |

Ready to achieve precise particle size analysis in your lab?

Accurate sieve analysis is critical for quality control, material characterization, and regulatory compliance. KINTEK specializes in high-quality laboratory sieves, sieve shakers, and consumables designed for durability and precision. Our equipment helps you generate reliable, repeatable data for your granular materials.

Contact us today to discuss your specific application and find the perfect sieving solution for your laboratory needs.

Get in touch with our experts!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What is the purpose of sieving in chemistry? Master Particle Size Control for Better Reactions & Quality

- Why must standard test sieves be used to screen silicon nitride ceramic powder? Ensure Uniformity and Strength

- What does a sieve test determine? A Guide to Accurate Particle Size Distribution

- What is the size range for sieving? From 125mm Gravel to 20µm Powders

- What range of particle size does the sieve analysis apply? Master the 25 Micron to 1 mm Standard

- What is the primary purpose of using a standard sieve in rice straw processing? Achieve Perfect Uniformity

- How is sieving important? The Critical Role of Particle Size Analysis in Quality Control

- What precautions should be taken when doing a sieve analysis? Ensure Accurate Particle Size Data