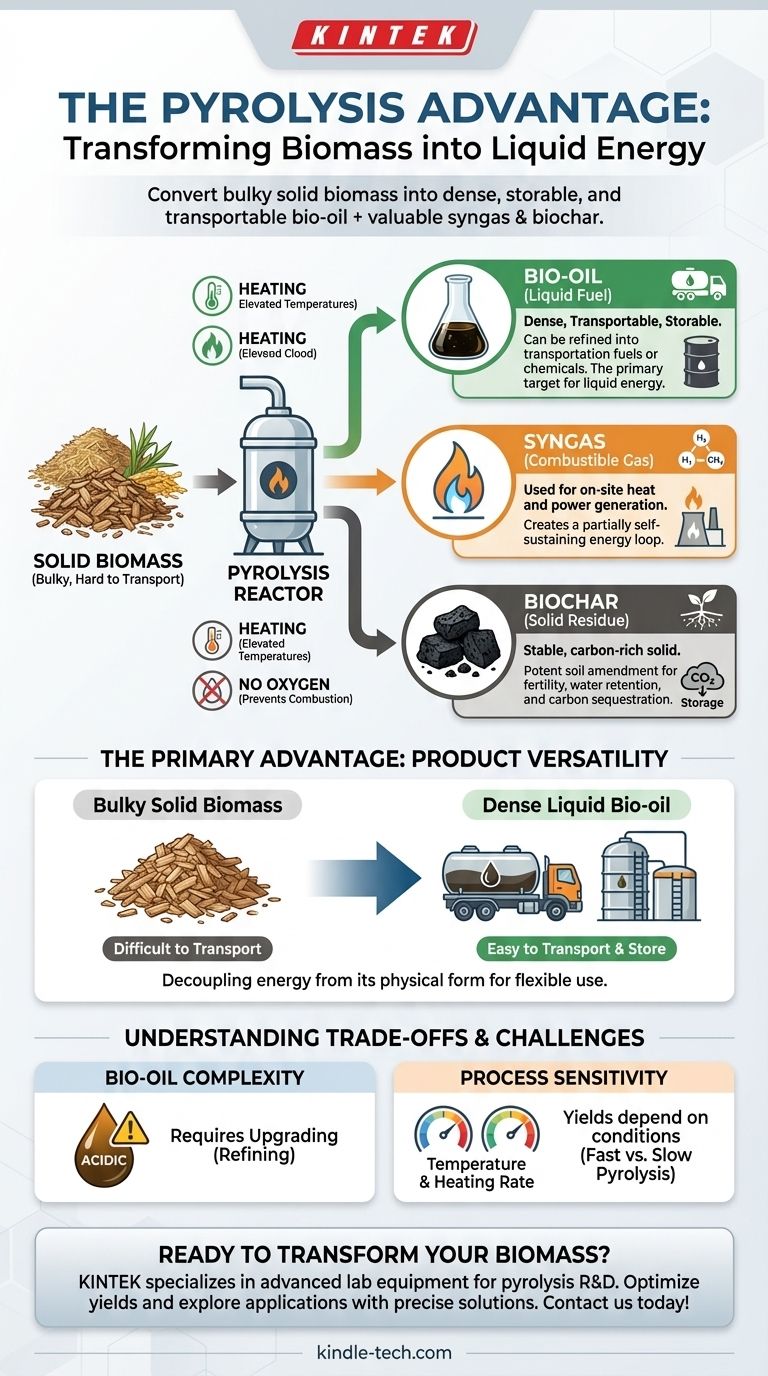

A major advantage of pyrolysis is its unique ability to convert bulky, solid biomass into a dense, storable, and transportable liquid fuel known as bio-oil. This thermal conversion process also co-produces other valuable outputs like syngas and biochar, offering a flexible suite of energy and material products from a single feedstock.

The core value of pyrolysis is not just energy production, but energy transformation. It converts low-density, difficult-to-handle solid biomass into more valuable and versatile energy carriers, primarily a liquid bio-oil that decouples the energy from its original physical form.

Deconstructing the Pyrolysis Process

To understand the advantages of pyrolysis, we must first understand what it is. It's a simple, yet powerful, thermochemical process.

The Core Principle: Heating Without Oxygen

Pyrolysis is the thermal decomposition of organic material at elevated temperatures in the complete absence of oxygen.

Crucially, preventing oxygen from entering the reactor ensures the biomass does not combust (burn). Instead of releasing its energy as immediate heat, the complex organic matter breaks down into simpler, more valuable molecules.

The Three Key Products

This controlled thermal breakdown results in three primary products, each with a distinct use.

- Bio-oil: A dark, viscous liquid that contains a complex mixture of oxygenated organic compounds. This is often considered the primary target product.

- Syngas (Synthesis Gas): A mixture of combustible gases, primarily hydrogen (H2), carbon monoxide (CO), carbon dioxide (CO2), and methane (CH4).

- Biochar: A stable, carbon-rich solid residue that is similar to charcoal.

The Primary Advantage: Product Versatility

The true strength of pyrolysis lies in its ability to generate multiple useful products, turning a single waste stream into several potential value streams.

From Solid Biomass to Liquid Fuel

The conversion of solid biomass into a liquid bio-oil is a significant logistical breakthrough. Solid biomass (like wood chips or crop residues) is bulky, has a high moisture content, and is expensive to transport over long distances.

Bio-oil is far more energy-dense by volume, making it storable and transportable in a way that raw biomass is not. This allows energy to be produced in one location and used in another, much like conventional liquid fuels.

Co-production of Valuable Syngas

The syngas produced during pyrolysis has immediate value. It is a combustible gas that can be captured and used to provide the heat needed to run the pyrolysis reactor itself.

This creates a partially self-sustaining energy loop, reducing the need for external energy inputs and improving the overall energy balance of the system.

The Biochar Co-product

The solid biochar that remains is not a waste product. It is a highly stable form of carbon.

This biochar can be used as a potent soil amendment to improve fertility and water retention, or it can be sequestered to lock carbon away from the atmosphere for centuries, acting as a form of carbon capture.

Understanding the Trade-offs

While powerful, pyrolysis is not a perfect solution. It's essential to recognize the associated challenges.

The Complexity of Bio-oil

Raw bio-oil is not a "drop-in" replacement for petroleum. It is acidic, corrosive, chemically unstable, and has a lower energy content than conventional fossil fuels.

Significant and often costly upgrading and refining are required to convert bio-oil into stable, usable transportation fuels or high-value chemicals.

Process Sensitivity

The relative yields of bio-oil, syngas, and biochar are highly dependent on the pyrolysis conditions, especially temperature and heating rate.

Fast pyrolysis (high temperatures, rapid heating) maximizes bio-oil yield, while slow pyrolysis (lower temperatures, slow heating) maximizes biochar. This requires precise process control to achieve the desired output consistently.

How to Apply This to Your Goal

The optimal use of pyrolysis depends entirely on your primary objective.

- If your primary focus is creating transportable fuel: You will use fast pyrolysis to maximize the yield of bio-oil, which can then be stored, moved, and refined.

- If your primary focus is on-site power generation: You can operate the process to balance the production of syngas and bio-oil, using the syngas to fuel a generator or the process itself.

- If your primary focus is carbon sequestration or soil improvement: You will use slow pyrolysis to maximize the production of stable, carbon-rich biochar.

Pyrolysis offers a uniquely flexible platform for converting biomass into a portfolio of valuable energy and material assets.

Summary Table:

| Pyrolysis Product | Key Characteristic | Primary Use |

|---|---|---|

| Bio-oil | Dense, transportable liquid fuel | Can be refined for energy or chemicals |

| Syngas | Combustible gas mixture (H2, CO, CH4) | On-site heat and power generation |

| Biochar | Stable, carbon-rich solid | Soil amendment or carbon sequestration |

Ready to transform your biomass into valuable energy and products? KINTEK specializes in advanced lab equipment for pyrolysis research and development. Whether you're optimizing bio-oil yield or exploring biochar applications, our solutions help you achieve precise, efficient results. Contact our experts today to discuss how we can support your laboratory's biomass conversion goals!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Non Consumable Vacuum Arc Induction Melting Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success