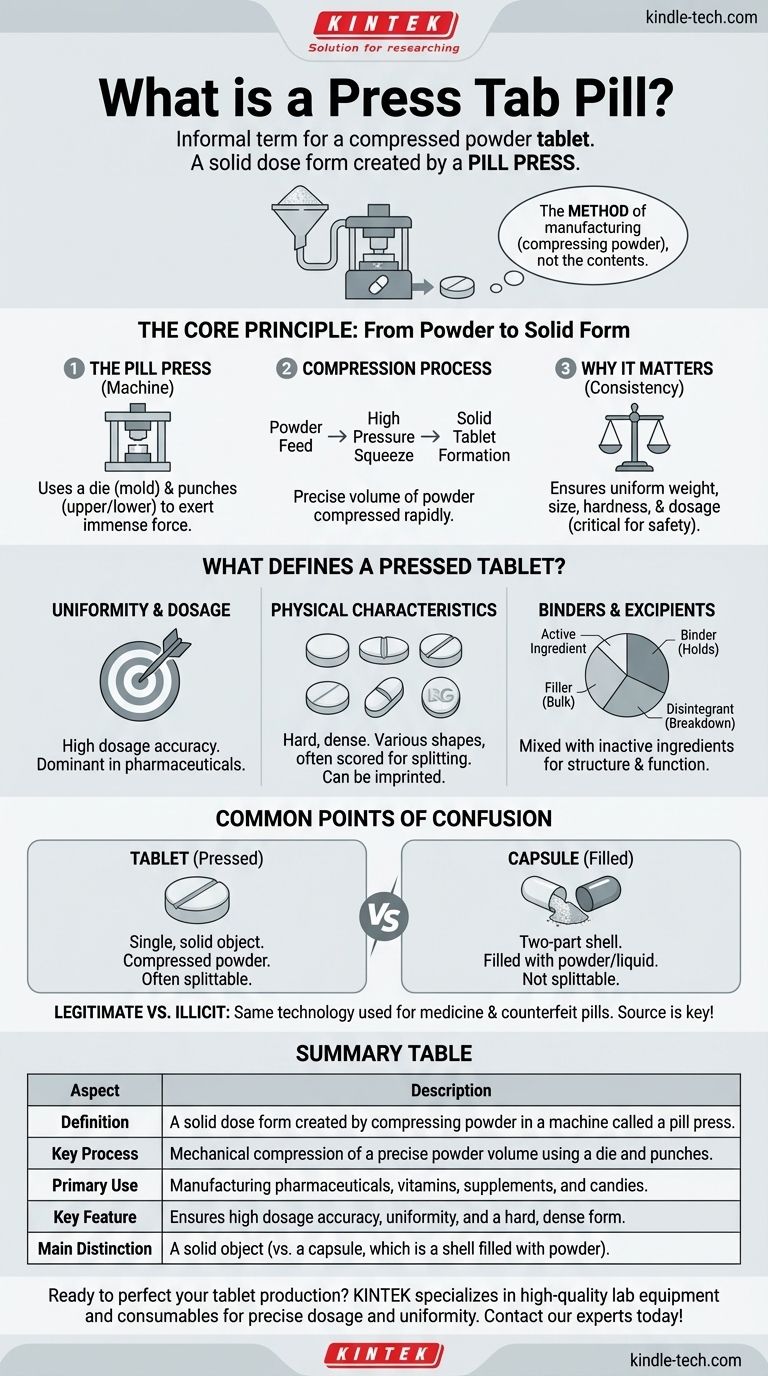

In short, a "press tab pill" is an informal term for a tablet. It refers to a solid dose form created by a mechanical device called a pill press, which compacts one or more powdered ingredients into a hard, smooth pill. This method is the foundation of modern manufacturing for a vast range of products, from pharmaceutical drugs and vitamins to candies.

The critical distinction is that the term "pressed tablet" describes the method of manufacturing—compressing powder—not the contents of the pill itself. This process creates a uniform, solid dose, unlike a capsule, which is a shell filled with loose powder.

The Core Principle: From Powder to Solid Form

The creation of a pressed tablet is a mechanical process focused on precision, density, and uniformity. It transforms loose, inconsistent powders into a solid object with predictable properties.

The Role of the Pill Press

A pill press, or tablet press, is the machine at the heart of this process. It uses a die (a mold that defines the tablet's shape) and two punches (upper and lower) to exert immense force on a measured amount of powder.

The Process of Compression

The manufacturing cycle is simple and rapid. First, a precise volume of the powder formulation is fed into the die cavity. Then, the punches come together to squeeze the powder under extreme pressure, forcing the particles to bond together into a solid tablet.

Why Compression Matters

This method ensures that every tablet produced has a consistent weight, size, hardness, and dosage of the active ingredient. This uniformity is absolutely critical for pharmaceuticals, where accurate dosing is a matter of safety and efficacy.

What Defines a Pressed Tablet?

While the core process is simple, the resulting product has specific characteristics that distinguish it from other dose forms like capsules or gelcaps.

Uniformity and Dosage

Because the powder is measured and compressed mechanically, pressed tablets offer exceptionally high dosage accuracy. This is a primary reason for their dominance in the pharmaceutical industry.

Physical Characteristics

Pressed tablets are hard and dense. They can be manufactured in various shapes (round, oval, etc.) and are often scored with a line to allow for easy splitting. Logos or dosage numbers can also be imprinted directly onto the surface during the compression stage.

The Use of Binders and Excipients

Rarely is a tablet made of just one ingredient. The primary powder is mixed with other substances called excipients. These inactive ingredients serve as binders to hold the tablet together, fillers to add bulk, and disintegrants to help it break down properly in the body.

Common Points of Confusion

Understanding pressed tablets also means understanding what they are not. The terminology can be a source of confusion, and the context of manufacturing is key.

"Tablet" vs. "Capsule"

This is the most common mix-up. A pressed tablet is a single, solid object made from compressed powder. A capsule is a two-part shell (often made of gelatin) that is filled with loose powder or liquid. You cannot split a capsule, but you can often split a scored tablet.

Legitimate vs. Illicit Manufacturing

The technology of the pill press is fundamental to the legitimate production of medicine, vitamins, and supplements. However, because these machines can be acquired by anyone, they are also widely used in the illicit manufacturing of counterfeit pills and recreational drugs.

Appearance Is Not an Indicator of Content

A professionally made pharmaceutical and a dangerously counterfeit pill can be physically indistinguishable. Both are made using the same core technology of a pill press. This is why the source of any medication is the most critical factor for safety.

Applying This Knowledge

Your understanding of a pressed tablet depends on your goal. Whether you are a patient, a producer, or simply curious, focusing on the right details is key.

- If your primary focus is taking medication correctly: Pay attention to the difference between a solid tablet (which may be splittable) and a capsule (which should not be opened unless directed).

- If your primary focus is product formulation (e.g., supplements): Recognize that success depends on the precise mixture of active ingredients and excipients needed to ensure proper compression and dissolution.

- If your primary focus is safety and awareness: Understand that the manufacturing method tells you nothing about the tablet's actual contents, making trusted sourcing essential.

Ultimately, knowing what a pressed tablet is means understanding that its form is a direct result of a specific and precise industrial process.

Summary Table:

| Aspect | Description |

|---|---|

| Definition | A solid dose form created by compressing powder in a machine called a pill press. |

| Key Process | Mechanical compression of a precise powder volume using a die and punches. |

| Primary Use | Manufacturing pharmaceuticals, vitamins, supplements, and candies. |

| Key Feature | Ensures high dosage accuracy, uniformity, and a hard, dense form. |

| Main Distinction | A solid object (vs. a capsule, which is a shell filled with powder). |

Ready to perfect your tablet production? Whether you're developing a new supplement line or scaling up pharmaceutical manufacturing, the right equipment is critical for achieving precise dosage, uniformity, and efficiency. KINTEK specializes in high-quality lab equipment and consumables for all your tablet pressing and formulation needs. Contact our experts today to find the perfect solution for your laboratory!

Visual Guide

Related Products

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- What are the different pill presses? Choose the Right Machine for Your Lab or Production Scale

- What is the use of tablet press? Transforming Powder into Precise, Uniform Tablets

- How fast is the rotary tablet press? Unlock Peak Production Speeds for Your Tablets

- What is the difference between single punch and rotary tablet press? Choose the Right Machine for Your Lab or Production

- How does a rotary tablet press work? A Guide to High-Speed Tablet Manufacturing