At its core, a punch tablet press is a machine designed to compress powder into tablets of a uniform size, shape, and weight. It operates on a principle of compression using a single set of tooling—a die and a pair of punches—to form one tablet at a time through a repetitive stamping motion.

The single punch tablet press is not a tool for mass production. Instead, it is a specialized instrument valued for its precision and simplicity, making it the definitive choice for research and development, material testing, and small-batch manufacturing.

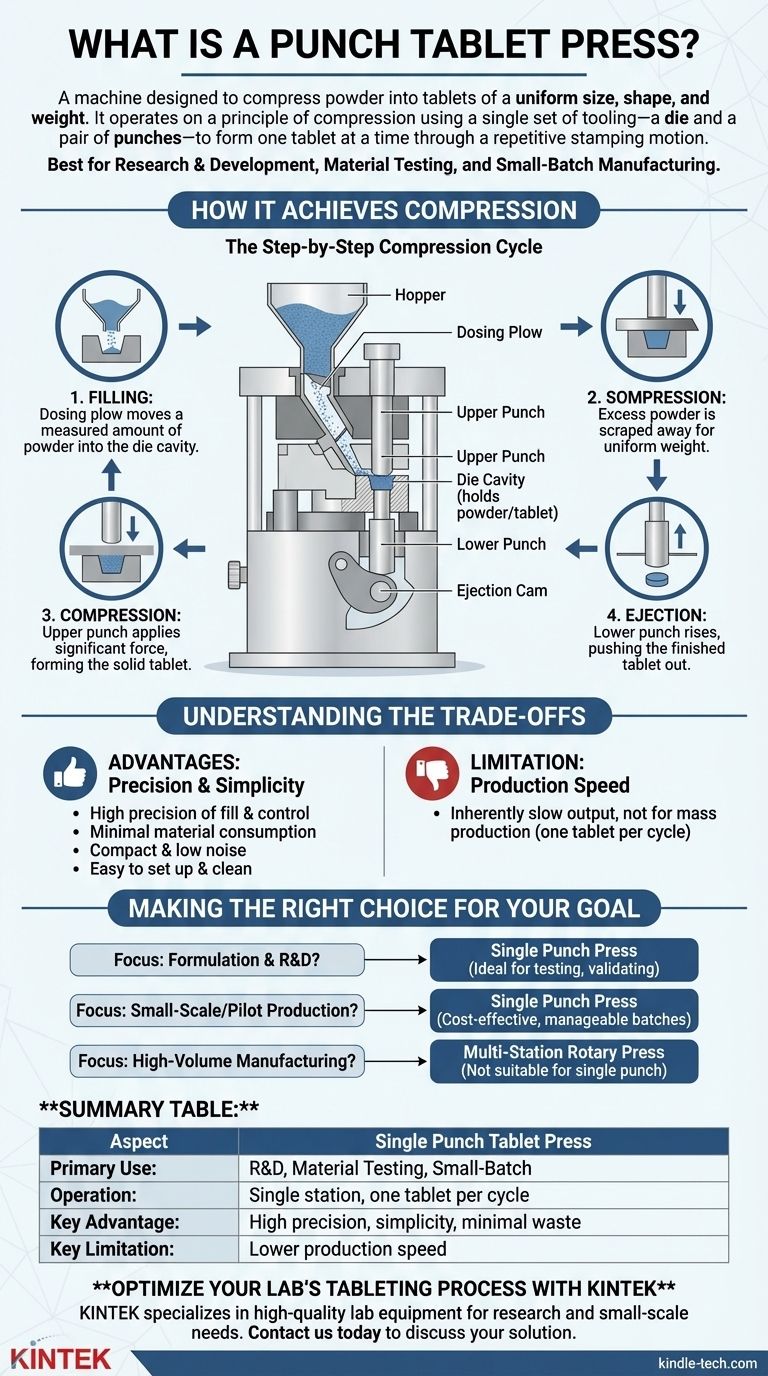

How a Tablet Press Achieves Compression

The fundamental function of any tablet press is to apply immense, controlled force to a granular or powdered material, forcing the particles to cohere into a solid form. This is accomplished through a precise, automated mechanical cycle.

The Core Components and Their Roles

A single punch press consists of several critical parts working in concert.

- Hopper: This funnel-shaped container holds the bulk powder or granular mixture that will be turned into tablets.

- Die Cavity: This is the mold that defines the final shape and diameter of the tablet. The powder is fed into this cavity for compression.

- Punches (Upper and Lower): These are the steel tools that directly compress the powder. The lower punch forms the bottom of the die cavity, while the upper punch descends to apply the compressive force.

- Dosing Plow: This component pushes a precise, repeatable volume of powder from the hopper's path into the die cavity, ensuring tablet weight consistency.

- Ejection Cam: This mechanism guides the lower punch upward after compression, pushing the finished tablet out of the die cavity for collection.

The Step-by-Step Compression Cycle

The machine operates through a continuous, cyclical process to produce each tablet.

- Filling: The lower punch is positioned low within the die, creating a cavity. The dosing plow then moves a measured amount of powder into this cavity.

- Scraping: Any excess powder is scraped away from the surface of the die to ensure a precise fill volume and uniform tablet weight.

- Compression: The upper punch descends with significant force into the die, compressing the powder between it and the stationary lower punch. This high-pressure action forms the solid tablet.

- Ejection: The upper punch retracts. The lower punch then rises, pushing the newly formed tablet up and out of the die cavity where it can be swept away. The cycle immediately repeats.

Understanding the Trade-offs

Choosing a single punch press involves a clear understanding of its distinct advantages and inherent limitations. It is a specialized tool, not a universal solution.

Advantage: Precision and Control

For laboratory and development work, the single punch press excels. Its simple design allows for high precision of fill, easy operation, and minimal material consumption. This makes it ideal for testing new formulations or confirming the compressibility of expensive or scarce materials.

Advantage: Simplicity and Small Footprint

These machines are typically compact, operate with low noise, and are straightforward to set up and clean. This makes them perfectly suited for research environments or small-scale production facilities where space and operational complexity are major concerns.

Limitation: Production Speed

The primary trade-off is output. Because it has only one station and produces one tablet per cycle, a single punch press is inherently slow. It is not a viable option for high-volume manufacturing, where multi-station rotary presses that produce thousands of tablets per minute are the standard.

Making the Right Choice for Your Goal

Selecting the correct equipment depends entirely on your project's objective. A single punch press is the right tool for specific, targeted applications.

- If your primary focus is formulation and R&D: The precision and low material waste of a single punch press make it the ideal instrument for testing and validating new products.

- If your primary focus is small-scale or pilot production: This machine provides a cost-effective and manageable solution for producing limited batches without the complexity of a large-scale setup.

- If your primary focus is high-volume manufacturing: A single punch press is unsuitable; your needs require a multi-station rotary tablet press designed for mass production.

Understanding the purpose of your tool is the first step toward achieving a successful outcome.

Summary Table:

| Aspect | Single Punch Tablet Press |

|---|---|

| Primary Use | Research & Development, Material Testing, Small-Batch Production |

| Operation | Single station, one tablet per cycle |

| Key Advantage | High precision, simplicity, minimal material waste |

| Key Limitation | Lower production speed (not for mass production) |

Optimize Your Lab's Tableting Process with KINTEK

Are you developing new formulations or producing small, precise batches? The precision and control of a single punch tablet press are essential for success. KINTEK specializes in supplying high-quality lab equipment, including reliable tablet presses, to meet your research and small-scale production needs.

Contact us today to discuss how the right tableting solution can save you time, reduce material waste, and accelerate your project from development to production.

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

People Also Ask

- How does a rotary tablet press work? A Guide to High-Speed Tablet Manufacturing

- How fast is the rotary tablet press? Unlock Peak Production Speeds for Your Tablets

- What are the benefits of pelletizing types of biomass? Unlock Efficient, Cost-Effective Biomass Handling

- What is the difference between pelleting and pelletizing? Understand the Core Agglomeration Methods

- What are the different parts of a single punch tablet machine? The Core Components Explained

- What is the use of a biomass pellet machine? Turn Waste into Fuel, Feed, and Bedding

- What are the different types of pellet mill die? Flat Die vs. Ring Die Explained

- How does a flat die pellet mill work? A Complete Guide to Small-Scale Pellet Production