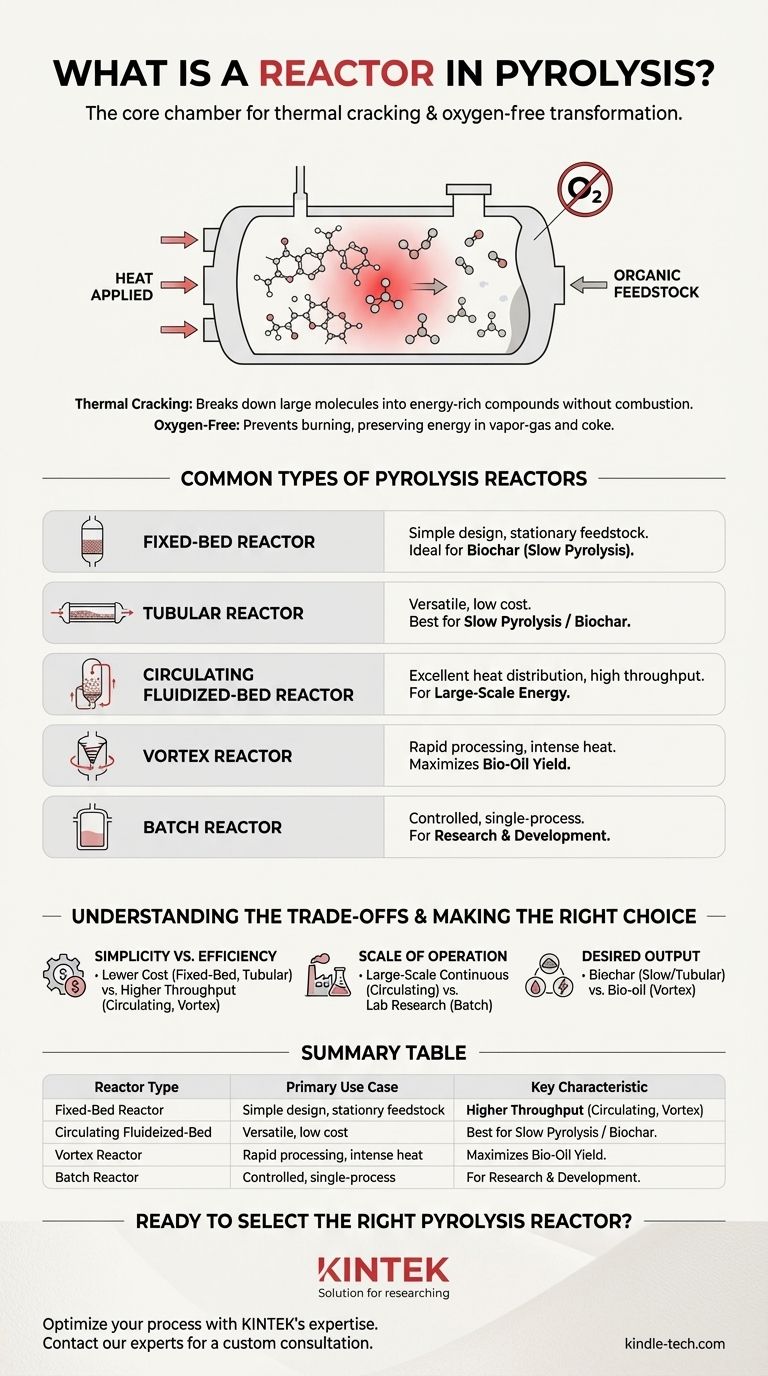

In a pyrolysis system, the reactor is the core chamber where the fundamental transformation occurs. It is a highly controlled, oxygen-free vessel where heat is applied to organic feedstock. This process, known as thermal cracking, breaks down large, complex molecules into smaller, energy-rich compounds without allowing them to burn.

A pyrolysis reactor is not merely a container; it is a precisely engineered environment designed to deconstruct materials using heat. The specific design of the reactor is the most critical factor determining the speed, efficiency, and final products of the entire pyrolysis process.

The Core Function of a Pyrolysis Reactor

At its heart, a pyrolysis reactor manages a chemical reaction under specific conditions. Its design is entirely focused on optimizing this transformation for a desired outcome.

The Principle of Thermal Cracking

The primary job of the reactor is to facilitate thermal cracking. Heat energy is transferred to the feedstock, causing the long-chain organic molecules to vibrate and break apart into smaller, more valuable molecules.

This happens without combustion because the reactor is sealed to exclude oxygen.

The Critical Role of an Oxygen-Free Environment

Preventing oxygen from entering the reactor is essential. In the presence of oxygen, the feedstock would simply burn (combust), releasing most of its energy as heat and CO₂.

By excluding oxygen, the reactor forces the material to decompose, preserving the chemical energy in new products like a vapor-gas mixture and solid coke (biochar).

Common Types of Pyrolysis Reactors

Reactor designs vary significantly based on how they handle feedstock and transfer heat. The choice of reactor directly impacts the process efficiency and the type of products generated.

Fixed-Bed Reactor

This reactor has a simple design where feedstock is placed on a stationary "bed." Heat is applied externally and diffuses through the vessel walls into the material.

It is straightforward and doesn't require complex fluid dynamics, making it a reliable choice for certain applications.

Tubular Reactor

A tubular reactor is valued for its simple design and relatively low operational costs. It is highly versatile and can perform slow, fast, or flash pyrolysis.

However, it is best suited for slow pyrolysis, a process that maximizes the production of biochar. It can operate using either fixed-bed or fluidized-bed principles.

Circulating Fluidized-Bed Reactor

This advanced design uses a fluidizing gas (like steam or nitrogen) to make the solid feedstock behave like a fluid.

Heated material is continuously circulated throughout the reactor, providing excellent heat distribution. This technology is used extensively for large-scale renewable energy production.

Vortex Reactor

Also known as a Gas/Solid Vortex Reactor (GSVR), this design uses a rotating bed, often driven by a centrifuge system, within an inert gas environment.

The rapid motion creates excellent mixing and heat transfer, making it highly effective for converting biomass into bio-oil and biochar.

Batch Reactor

A batch reactor processes a single, fixed amount of feedstock at a time. It is not designed for continuous industrial production.

Instead, its primary use is in laboratory settings for research, particularly for investigating the energy stability and characteristics of pyrolytic reactions.

Understanding the Trade-offs

No single reactor design is universally superior. The optimal choice depends on a balance between cost, efficiency, feedstock, and desired output.

Simplicity vs. Efficiency

Simpler designs like fixed-bed and tubular reactors have lower construction and operational costs. However, they often have less efficient heat transfer compared to more complex systems.

Conversely, circulating and vortex reactors offer superior heat distribution and higher throughput but come with increased mechanical complexity and cost.

Scale of Operation

The intended scale is a critical factor. A batch reactor is perfect for research and development but impractical for industrial output.

Circulating fluidized-bed reactors, on the other hand, are engineered specifically for large-scale, continuous processing needed for commercial electricity generation.

Desired Output

The reactor's design directly influences the final products. A slow process in a tubular reactor is ideal if the goal is to maximize solid biochar.

If the primary goal is liquid bio-oil, the rapid heat transfer and short residence times of a vortex reactor are often preferred.

Making the Right Choice for Your Application

Selecting the correct reactor requires a clear understanding of your primary objective.

- If your primary focus is low-cost processing for biochar production: A tubular or fixed-bed reactor provides a simple, cost-effective solution well-suited for slow pyrolysis.

- If your primary focus is large-scale, efficient energy generation: A circulating fluidized-bed reactor delivers the high throughput and excellent heat transfer necessary for commercial applications.

- If your primary focus is maximizing bio-oil from biomass: A vortex reactor offers the rapid processing and intense heat transfer needed to favor the production of liquid fuels.

- If your primary focus is research and process analysis: A batch reactor provides the controlled, small-scale environment essential for detailed scientific investigation.

Ultimately, understanding the reactor's design is the key to controlling the pyrolysis process and achieving your specific material or energy goals.

Summary Table:

| Reactor Type | Primary Use Case | Key Characteristic |

|---|---|---|

| Fixed-Bed | Slow Pyrolysis / Biochar | Simple, low-cost design |

| Tubular | Slow Pyrolysis / Biochar | Versatile, reliable operation |

| Circulating Fluidized-Bed | Large-Scale Energy Production | Excellent heat distribution, high throughput |

| Vortex | Maximizing Bio-Oil Yield | Rapid processing, intense heat transfer |

| Batch | Research & Development | Controlled, small-scale environment |

Ready to select the right pyrolysis reactor for your specific goals?

The choice of reactor is the most critical decision in designing an efficient pyrolysis system. Whether your focus is biochar production, bio-oil yield, or large-scale energy generation, KINTEK's expertise in lab and industrial equipment can help you optimize your process.

We provide the technology and consumables to support your pyrolysis R&D and scale-up. Contact our experts today to discuss your application and discover the right solution for your laboratory or production needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- Why glass lined reactors are used? Achieve Unmatched Purity & Corrosion Resistance

- What is the primary function of a high-pressure reactor in methane oxidation? Unlock Liquid-Phase Efficiency

- What are some important factors to monitor in a bioreactor? Essential Parameters for Optimal Bioprocess Control

- What role does a stainless steel pressure vessel play in SHS of Ti3SiC2? Ensuring Purity and Real-Time Monitoring

- Why is a high-pressure hydrothermal reactor essential for synthesizing silica nanocomposites? Achieve Precision Design

- Why is a high-temperature reactor filled with titanium sponge utilized? Ensure Single-Phase Purity in Fe-Ti Alloys

- What conditions does a reactor provide for nitrobenzene reduction? Optimize H2 Solubility for Aniline Purity

- What role does a high-pressure laboratory reactor play in the hydrothermal synthesis of zeolites? Essential Guide