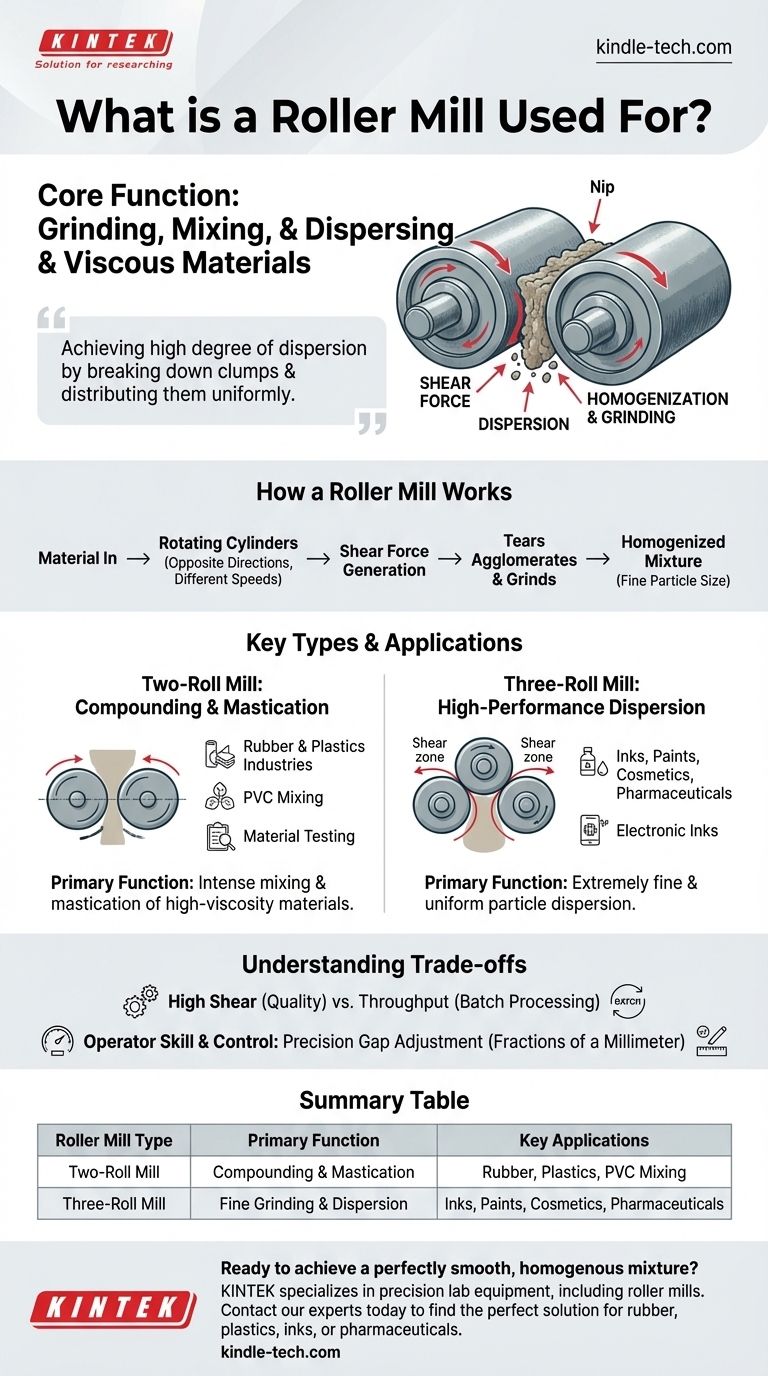

At its core, a roller mill is a machine used to grind, mix, or disperse viscous materials. It leverages the immense shear force generated between rotating cylinders to break down particles and create a smooth, homogenous mixture. Key applications range from compounding rubber and plastics to producing high-quality inks, paints, cosmetics, and pharmaceuticals.

The essential purpose of a roller mill is not just mixing, but achieving a high degree of dispersion. It excels at breaking down clumps of solid particles and distributing them uniformly within a liquid or semi-solid base, a task that simple mixers cannot accomplish.

The Core Function: Shear Force and Dispersion

How a Roller Mill Works

A roller mill operates on a simple but powerful principle. Material is fed into the gap, or "nip," between two or more large, heavy rollers.

These rollers rotate in opposite directions and at different speeds. This speed differential is what creates the intense shear force that processes the material.

The Goal: Homogenization and Grinding

As the material is pulled through the nip, the shear force tears apart agglomerates (clumps of particles) and grinds them down.

The result is a thoroughly homogenized mixture with a consistent, fine particle size. This process is critical for the quality, texture, and performance of the end product.

Key Types and Their Applications

The number of rollers is the primary differentiator, determining the machine's specific function and the materials it is best suited to handle.

The Two-Roll Mill: For Compounding and Mastication

The two-roll mill is a workhorse for the plastics and rubber industries. Its primary function is to mix and compound high-viscosity materials.

Common uses include PVC powder mixing, creating polymer and rubber compound samples, material testing, and quality control. It's less about fine grinding and more about physically working the material to blend additives and achieve desired properties.

The Three-Roll Mill: For High-Performance Dispersion

The three-roll mill is the standard for applications requiring extremely fine and uniform particle dispersion in a liquid or paste base. It creates two distinct shear zones, offering superior control and a finer grind.

It is indispensable for producing high-performance ceramics, electronic thick film inks, paints, printing inks, cosmetics, pharmaceuticals, adhesives, and even some foods.

Understanding the Trade-offs

High Shear vs. Throughput

Roller mills generate unparalleled shear force, which is essential for high-quality dispersion. However, they are typically batch processors, not continuous systems.

This makes them ideal for product development, quality control, and producing high-value materials where consistency is paramount, but potentially less efficient for mass-producing low-cost bulk goods.

Operator Skill and Control

Achieving the perfect dispersion requires skill. The operator must precisely control the gap between the rollers, which can be adjusted to fractions of a millimeter.

While this allows for exceptional fine-tuning, it also means that results depend on a properly set up and managed process. It is a tool of precision, not just brute force.

Making the Right Choice for Your Goal

- If your primary focus is compounding solids like rubber or plastics: A two-roll mill is the standard tool designed for the intense mixing and mastication these materials require.

- If your primary focus is creating a perfectly smooth paste or liquid (like inks, paints, or ointments): A three-roll mill provides the superior shear and control needed for fine particle dispersion.

- If your primary focus is material development and quality control: Both mill types are invaluable lab instruments for testing formulations and ensuring product consistency.

Ultimately, selecting the correct roller mill depends entirely on the physical properties of your material and the final texture you need to achieve.

Summary Table:

| Roller Mill Type | Primary Function | Key Applications |

|---|---|---|

| Two-Roll Mill | Compounding & Mastication | Rubber, Plastics, PVC Mixing |

| Three-Roll Mill | Fine Grinding & Dispersion | Inks, Paints, Cosmetics, Pharmaceuticals |

Ready to achieve a perfectly smooth, homogenous mixture?

KINTEK specializes in precision lab equipment, including roller mills for compounding and dispersion. Whether you're developing new materials in R&D or ensuring quality control in production, our expertise helps you achieve superior results.

Contact our experts today to find the perfect roller mill for your application in rubber, plastics, inks, or pharmaceuticals.

Visual Guide

Related Products

- Laboratory High Throughput Tissue Grinding Mill Grinder

- Laboratory Hybrid Tissue Grinding Mill

- Laboratory Disc Cup Vibratory Mill for Sample Grinding

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill with Screw Feeder

People Also Ask

- How much balls should be loaded in a ball mill for working? Optimize Grinding with the Correct Ball Charge

- What is the role of a laboratory-scale ball mill in the pretreatment of microalgae biomass? Boost Cell Wall Disruption

- How many balls are needed for a ball mill? Optimize grinding with the right charge volume.

- Which tool could be used to pulverize an object? Match the Tool to Your Material's Hardness and Brittleness

- How does ball milling assist in the modification of materials for biomass binders? Optimize Your Dry Electrode Performance