In essence, a sieving shaker is a laboratory instrument designed to automate the process of particle size analysis. It uses a consistent, repeatable mechanical motion to agitate a stack of test sieves, efficiently separating a granular material into different size fractions. This process is fundamental for quality control and research in countless industries.

The core purpose of a sieving shaker is to replace inconsistent manual shaking with a controlled, reliable method. This ensures that particle size data is accurate and reproducible, which is critical for meeting industry standards and understanding material properties.

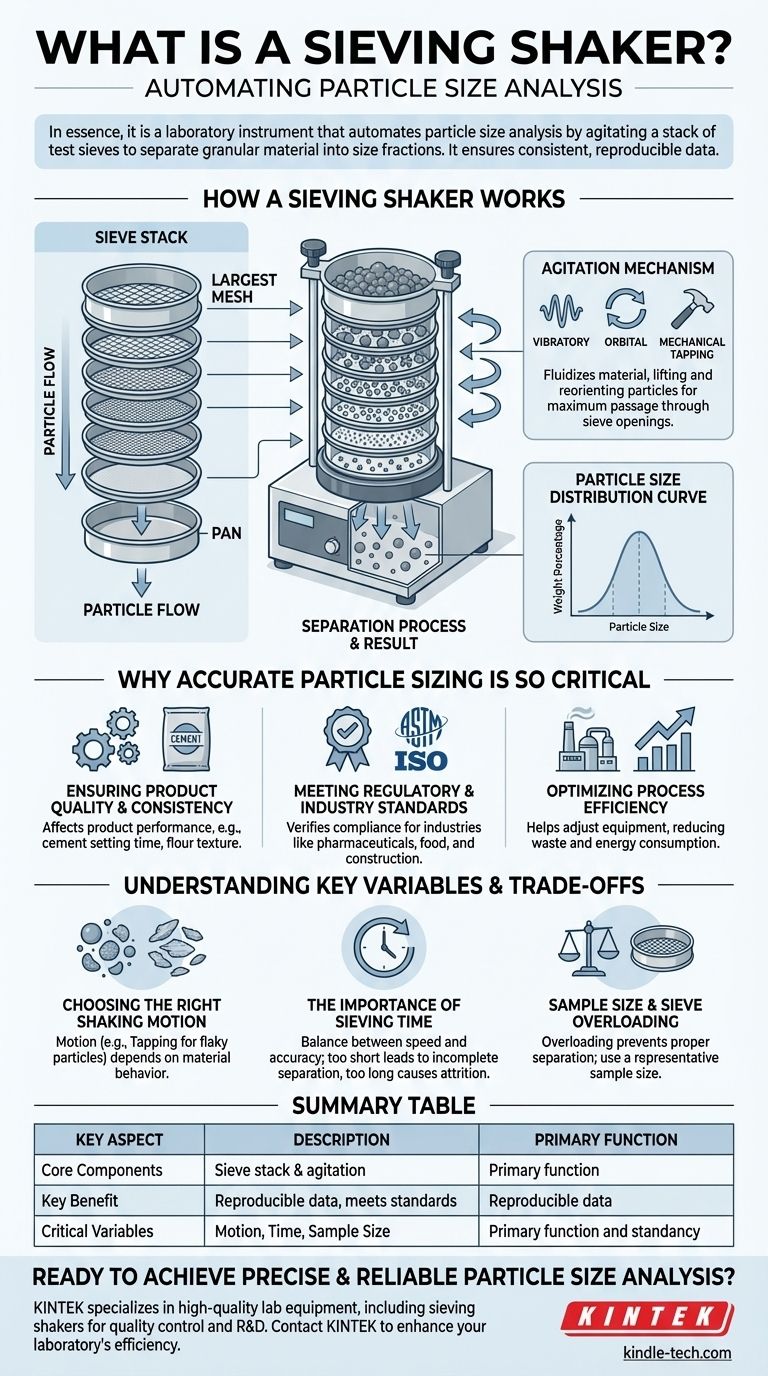

How a Sieving Shaker Works: The Core Principles

A sieving shaker operates on a straightforward mechanical principle, but its precision is key to its value. The system is comprised of a few critical components working in concert.

The Sieve Stack

The foundation of any analysis is the sieve stack. This is a column of nested test sieves, each with a precisely manufactured wire mesh or perforated plate bottom.

The sieve with the largest mesh opening is placed at the top of the stack, with each subsequent sieve below it having progressively smaller openings. A solid collection pan is placed at the very bottom.

The Agitation Mechanism

The user places a pre-weighed sample of material onto the top sieve, secures the stack in the machine, and sets a timer. The shaker then imparts a specific motion to the entire stack.

The goal of this motion is to fluidize the material, lifting and reorienting the particles to give each one the maximum opportunity to pass through a sieve opening if it is small enough. Common motions include vibratory, orbital, and mechanical tapping.

The Separation Process

As the machine runs, particles travel down the stack until they reach a sieve with openings too small for them to pass through.

At this point, they are retained on that sieve's mesh. The process continues until the smallest particles are collected in the bottom pan.

The Result: A Particle Size Distribution

After the cycle is complete, the material retained on each individual sieve is carefully collected and weighed. This data allows an analyst to determine the weight percentage of particles within each size range.

This information is then used to generate a particle size distribution curve, a critical metric that characterizes the material.

Why Accurate Particle Sizing is So Critical

Understanding and controlling particle size is not an academic exercise; it has a direct impact on product performance, safety, and manufacturing efficiency.

Ensuring Product Quality and Consistency

The properties of many products are directly tied to the size of their constituent particles. For example, the particle size of cement determines its setting time and strength, while the grind of flour affects the texture of baked goods. A sieving shaker provides the data needed to ensure this consistency.

Meeting Regulatory and Industry Standards

Many industries, from pharmaceuticals and food to construction and mining, operate under strict standards (such as ASTM or ISO) that specify acceptable particle size distributions. Sieve analysis is the benchmark method for verifying compliance with these regulations.

Optimizing Process Efficiency

Particle size data helps optimize industrial processes like grinding, milling, and spraying. By monitoring the output, manufacturers can adjust their equipment to avoid wasting energy on over-grinding or producing a product that is out of specification.

Understanding the Trade-offs and Key Variables

While the concept is simple, achieving accurate results requires an understanding of several key factors.

Choosing the Right Shaking Motion

Different materials behave differently. A simple vibratory motion is often sufficient for spherical, free-flowing materials. However, for flaky or elongated particles that can block sieve openings, a shaker with a mechanical tapping motion is often necessary to dislodge them and ensure proper separation.

The Importance of Sieving Time

There is a trade-off between speed and accuracy. An insufficient run time will result in an incomplete separation, skewing the results toward larger particle sizes. Conversely, excessive sieving time is inefficient and can cause attrition—the breakdown of particles from the agitation itself—which inaccurately skews results toward smaller sizes.

Sample Size and Sieve Overloading

One of the most common errors is overloading the sieves. If too much material is placed on a sieve, the layer is too thick for all particles to have a chance to reach the mesh surface. This prevents proper separation and leads to inaccurate results. It's often better to use a smaller, representative sample.

Making the Right Choice for Your Goal

To apply this knowledge effectively, consider the primary objective of your analysis.

- If your primary focus is routine quality control: Prioritize a robust shaker with digital controls for time and amplitude to guarantee consistent and repeatable testing conditions day after day.

- If your primary focus is research and development: You need flexibility. A model that offers multiple agitation modes (e.g., both vibration and tapping) will allow you to characterize a wider variety of known and unknown materials.

- If your primary focus is handling very fine or cohesive powders: A standard mechanical shaker may struggle. You should investigate specialized systems like sonic sifters or air jet sieves designed to overcome the forces that make fine powders clump together.

Ultimately, a sieving shaker transforms the simple act of sifting into a powerful source of analytical data for process control and innovation.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Function | Automates particle separation by size using controlled mechanical agitation. |

| Core Components | Sieve stack (with progressively smaller mesh sizes) and an agitation mechanism. |

| Key Benefit | Replaces manual shaking for consistent, reproducible data that meets industry standards (ASTM/ISO). |

| Critical Variables | Agitation motion (vibratory, orbital, tapping), sieving time, and sample size. |

Ready to achieve precise and reliable particle size analysis in your lab?

KINTEK specializes in high-quality lab equipment and consumables, including a range of sieving shakers designed for accuracy and durability. Whether your focus is routine quality control or advanced R&D, our experts can help you select the perfect instrument for your specific materials and standards.

Contact our team today to discuss your application and discover how KINTEK can enhance your laboratory's efficiency and data integrity.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What is the critical function of high-precision sieving for aluminum powders? Ensure Uniform Composite Integrity

- What is the importance of powder sieving and mixing systems in additive manufacturing for HEA? Unlock Advanced Alloys

- What key role does sieving equipment play for SiC/ZTA ceramic powder? Ensure Uniform Density & Defect-Free Sintering

- What is the function of a benchtop shaker in zirconium extraction? Achieve Rapid Chemical Equilibrium Efficiency

- What is the function of a laboratory shaker during batch adsorption experiments? Optimize Fly Ash Kinetic Research

- What is the aperture size of sieve shaker? Understanding the Key Components for Accurate Particle Analysis

- How do laboratory constant temperature shakers ensure material uniformity? Optimize Bimetallic Nanocatalyst Synthesis

- What is the use of sieve shaker in laboratory? Automate Particle Size Analysis for Accurate Results