At its core, a test sieve is a calibrated screening instrument used to separate particles of a material based on their size. It consists of a high-precision mesh screen with uniform openings held under tension in a rigid, circular frame. When used correctly, a sieve allows you to determine the particle size distribution of a sample, a critical quality metric in industries from pharmaceuticals and food to mining and agriculture.

A test sieve is more than a simple filter; it is a component in a larger analytical system. Its true purpose is to work in a stacked series, agitated by a shaker, to generate a reliable particle size distribution curve—the foundational data for ensuring material consistency and quality.

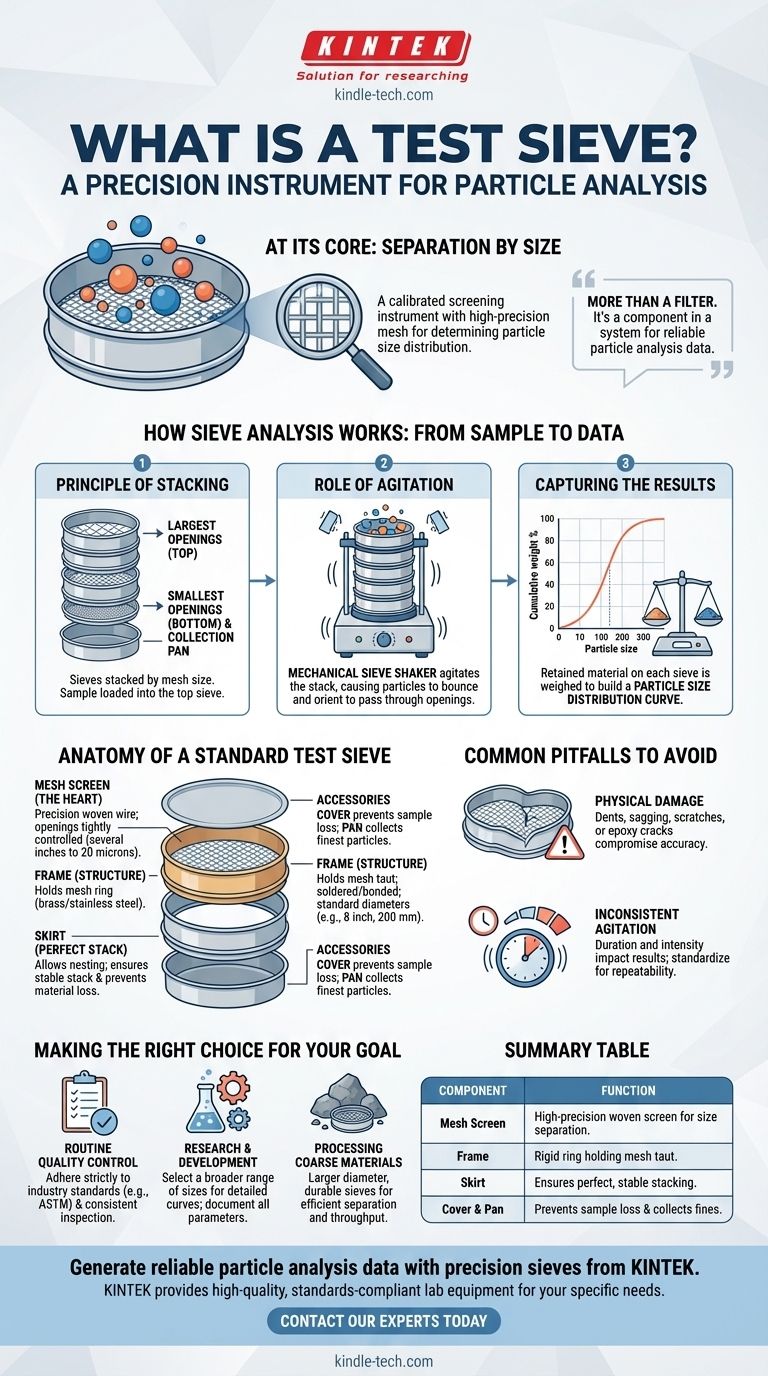

How Sieve Analysis Works: From Sample to Data

A single test sieve can only tell you if particles are larger or smaller than one specific size. Its real power is unlocked when multiple sieves are used together in a process called sieve analysis.

The Principle of Sieve Stacking

Sieves are stacked in order of mesh size, with the sieve having the largest openings on top and the one with the smallest openings near the bottom. A solid collection pan is placed at the very bottom of the stack.

The material sample to be analyzed is placed in the top sieve.

The Role of Agitation

The entire stack of sieves is placed in a mechanical sieve shaker. This device agitates the stack, usually with a combination of vibration and tapping motions.

This agitation causes the particles to bounce and reorient, giving each one an opportunity to pass through the mesh openings until it reaches a sieve it is too large to pass through.

Capturing the Results

After a set period of agitation, the particles are distributed throughout the stack. The material retained on each sieve is weighed.

By calculating the weight percentage of material on each sieve, you can build a particle size distribution curve. This curve provides a detailed fingerprint of the material's physical character.

Anatomy of a Standard Test Sieve

While it appears simple, a test sieve is a precision instrument where each component plays a critical role in ensuring accurate and repeatable results.

The Mesh Screen: The Heart of the Sieve

The screen is the most technical component, typically made of woven stainless steel wire. The size of its openings is tightly controlled according to industry standards like ASTM or ISO.

Opening sizes can range from several inches (or 100+ mm) for coarse materials down to just 20 microns (equivalent to 635 mesh) for very fine powders.

The Frame: Providing Structure

The frame is a rigid circular ring, most often made of brass or stainless steel, that holds the mesh taut. The mesh is typically soldered or bonded with a high-strength epoxy to the frame.

Frames come in standard diameters to ensure interoperability. Common sizes in the U.S. are 3, 8, and 12 inches, while international standards are typically 100, 200, and 300 mm.

The Skirt: Ensuring a Perfect Stack

Below the frame is a skirt, which is a slightly narrower ring that allows one sieve to nest perfectly on top of the one below it. This ensures the stack is stable and prevents material from escaping between sieves during agitation.

Accessories: Covers and Pans

A sieve cover is placed on the top sieve to prevent any loss of sample material during shaking. A collection pan, which has no mesh, sits at the bottom of the stack to collect the finest particles that pass through all the screens.

Common Pitfalls to Avoid

The accuracy of your particle size analysis depends entirely on the condition of your sieves and the consistency of your method.

Physical Damage Compromises Accuracy

You must regularly inspect sieves for any damage. Dents, sagging, or scratches in the mesh can distort the opening sizes, directly leading to incorrect results.

Cracks in the epoxy that bonds the mesh to the frame can create a pathway for particles to bypass the screen, which will skew the final particle count on lower sieves.

Inconsistent Agitation

The duration and intensity of shaking significantly impact results. Insufficient shaking will not give all particles enough opportunity to pass through the mesh, while excessive shaking can cause particle degradation (attrition).

For repeatable results, the parameters on the sieve shaker (time and amplitude) must be standardized and used consistently for every test.

Making the Right Choice for Your Goal

Using a test sieve effectively requires matching the tool and procedure to your specific analytical objective.

- If your primary focus is routine quality control: Adhere strictly to the sieve sizes and testing procedures specified by your industry standards (e.g., ASTM) and implement a consistent inspection schedule.

- If your primary focus is research and development: Select a broader range of sieve sizes to build a highly detailed distribution curve and meticulously document all testing parameters to ensure your results are reproducible.

- If your primary focus is processing coarse materials (e.g., agriculture, mining): You will require larger diameter, more durable sieves, where the main goal is efficient separation and throughput, not necessarily micron-level precision.

Understanding the test sieve as a precision instrument is the first step toward generating reliable and actionable particle analysis data.

Summary Table:

| Component | Function |

|---|---|

| Mesh Screen | High-precision woven screen with uniform openings to separate particles by size. |

| Frame | Rigid ring (brass/stainless steel) that holds the mesh taut for structural integrity. |

| Skirt | Ensures a perfect, stable stack when multiple sieves are nested together. |

| Cover & Pan | Prevents sample loss (cover) and collects fine particles that pass all screens (pan). |

Generate reliable particle analysis data with precision sieves from KINTEK.

Whether your focus is routine quality control, R&D, or processing coarse materials, the right test sieve is critical for accurate results. KINTEK specializes in high-quality lab equipment and consumables, providing the durable, standards-compliant sieves and shakers your laboratory needs to ensure material consistency and quality.

Contact our experts today to discuss your specific particle analysis requirements and find the perfect sieve solution for your application.

Visual Guide

Related Products

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Small Lab Rubber Calendering Machine

- Automatic Laboratory Heat Press Machine

People Also Ask

- What equipment do you need for sieving? Build a Precise Particle Analysis System

- Why would you use a sieve on your soil sample? To Determine Grain Size Distribution for Engineering

- What is the sieve method for particle size determination? A Guide to Simple, Cost-Effective Analysis

- What is the sample size recommended for the sieve analysis? Avoid Overloading for Accurate Results

- What is the basis of selecting the size of the sieves for the sieve analysis of the given aggregates? Follow the Standard for Accurate Gradation

- What is sieve screening? A Guide to Particle Size Distribution Analysis

- Can sieving be used to separate mixtures having components of different sizes? A Guide to Efficient Particle Separation

- What is a sieve used for sieving? A Guide to Precision Particle Size Analysis