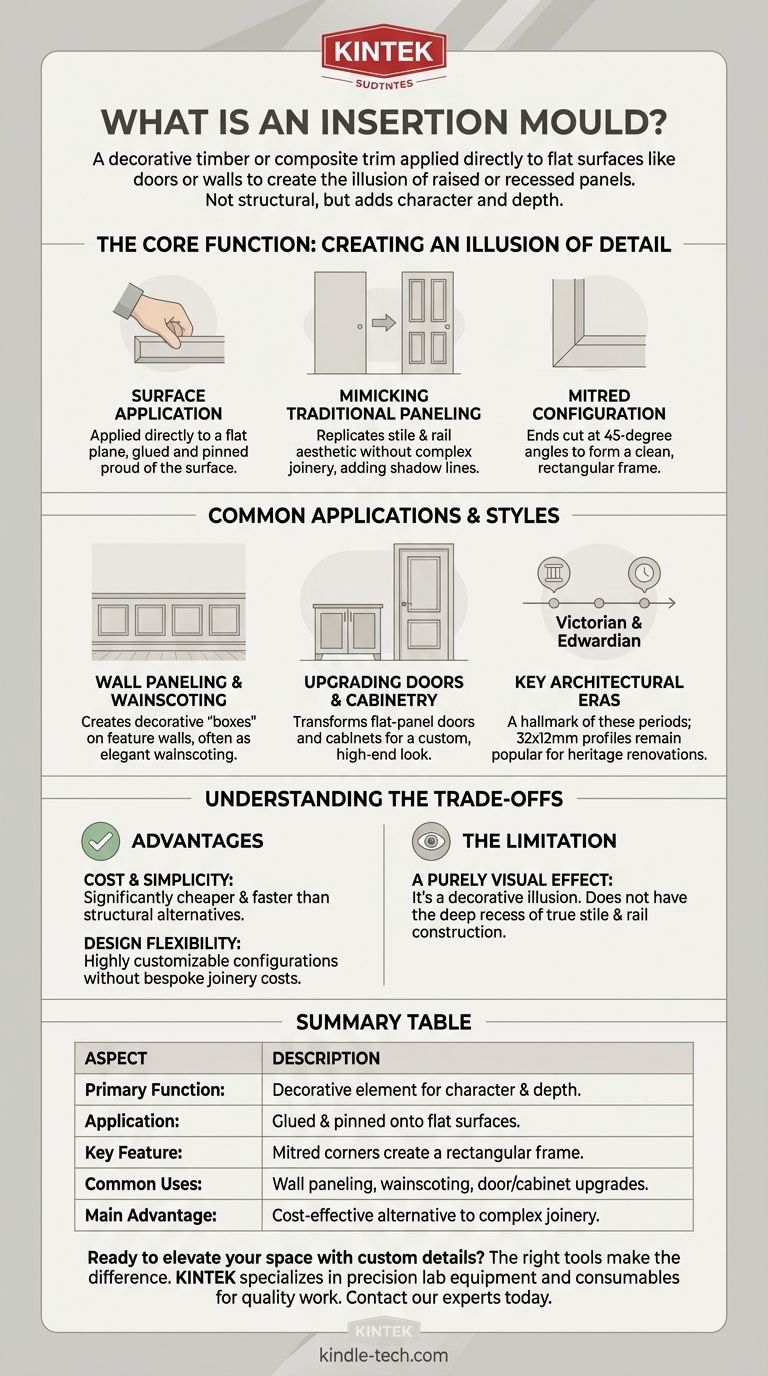

In short, an insertion mould is a type of decorative timber or composite trim applied directly onto a flat surface, such as a door or wall. It is cut and joined with mitred corners to form a rectangular or square frame, creating the visual illusion of a traditional raised or recessed panel.

An insertion mould is not a structural component but a decorative element. Its primary purpose is to add architectural character, depth, and detail to plain surfaces in a simple and cost-effective way, mimicking the look of more complex and expensive panel construction.

The Core Function: Creating an Illusion of Detail

An insertion mould is a design tool used to elevate simple surfaces. Its effectiveness comes from its simplicity.

How It Works: Surface Application

Unlike mouldings that cap or transition between surfaces (like skirting boards or cornices), an insertion mould is applied directly to the middle of a flat plane. It is glued and pinned in place, sitting proud of the main surface.

The term "insertion" refers to how it creates the look of an inserted panel within a larger frame, even though the panel is simply the original flat surface itself.

The Goal: Mimicking Traditional Paneling

Historically, doors and wall panels were constructed using a "stile and rail" method, where vertical (stiles) and horizontal (rails) pieces of wood framed a central panel. This created genuine depth and shadow lines.

Insertion moulding replicates this aesthetic without the complex joinery. It adds the shadow lines and perceived depth of traditional paneling to a modern, flat-surface door or wall.

The "Mitred Configuration"

To create the effect of a frame, the ends of the moulding pieces are cut at 45-degree angles. When four pieces are joined, they form a clean, professional-looking rectangle. This is known as a mitred configuration and is essential for achieving the panelled look.

Common Applications and Styles

While originating in classic design, this technique is versatile and used across several architectural styles to add a layer of sophistication.

Wall Paneling and Wainscoting

One of the most common uses is creating decorative "boxes" on a feature wall. This adds texture and a sense of formality to a room. When applied to the lower third of a wall, it forms a style of wainscoting that is elegant and visually anchoring.

Upgrading Doors and Cabinetry

A plain, flat-panel interior door or cabinet front can be instantly transformed with the addition of insertion moulds. This is a popular and budget-friendly way to achieve a custom, high-end look, often associated with Hamptons, French Provincial, or classic traditional styles.

Key Architectural Eras

As noted, these mouldings were a hallmark of the Victorian and Edwardian periods, where layering detail was a sign of quality. The typical 32x12mm profile from that era remains a popular choice for heritage-style renovations.

Understanding the Trade-offs

While highly effective, it's important to understand what an insertion mould is—and what it isn't.

Advantage: Cost and Simplicity

The primary benefit is cost. Applying moulding is significantly cheaper and faster than replacing an entire set of doors or constructing true, structural wainscoting. It is an accessible project for both professionals and skilled DIY enthusiasts.

Advantage: Design Flexibility

You can create nearly any configuration of squares and rectangles to suit your specific wall dimensions or design vision. This allows for a high degree of customization without the cost of bespoke joinery.

The Limitation: A Purely Visual Effect

It is crucial to remember this is a decorative illusion. The "panel" does not have the same deep recess as a true stile and rail door. From a distance, the effect is perfect; up close, it is clear that the moulding is an applied layer.

Making the Right Choice for Your Project

Your decision should be guided by your project's goals, budget, and desired level of authenticity.

- If your primary focus is historical accuracy and a premium finish: Consider investing in true stile and rail doors and custom-built structural wainscoting.

- If your primary focus is adding character and visual interest cost-effectively: Insertion moulding is the ideal solution for transforming flat, uninspired surfaces.

- If you are upgrading a standard new-build home: Using insertion moulds is one of the most impactful ways to add a sense of custom architecture and timeless appeal.

By understanding its function as a decorative layer, you can use insertion moulding to dramatically elevate the character of any space.

Summary Table:

| Aspect | Description |

|---|---|

| Primary Function | Decorative element to add architectural character and depth to plain surfaces. |

| Application | Glued and pinned directly onto flat surfaces like doors and walls. |

| Key Feature | Mitred corners create a rectangular frame, mimicking traditional paneling. |

| Common Uses | Wall paneling, wainscoting, and upgrading doors/cabinets. |

| Main Advantage | Cost-effective alternative to complex, structural joinery. |

Ready to elevate your space with custom architectural details? The right tools make all the difference. KINTEK specializes in precision lab equipment and consumables for professionals who value accuracy and quality in their work. Contact our experts today to find the perfect solutions for your project needs.

Visual Guide

Related Products

- Square Bidirectional Pressure Mold for Lab Use

- Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- High Purity Zinc Foil for Battery Lab Applications

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- What role do metal molds play during the cold pressing stage of VC/Cu composite fabrication? High-Precision Shaping

- What is the core function of a Graphite Mold in Ti-6Al-4V hot-pressing? Enhance Your Material Densification

- What are the stages of the molding process? A Guide to Plastic, Metal, and Ceramic Molding

- What is the price of a mold press machine? Understand the True Cost & Investment for Your Production

- What is positive compression molding? Achieve High-Precision, Zero-Waste Manufacturing

- What are the advantages of TZM alloy molds for solid-state batteries? Achieve high density and prevent lithium loss.

- What roles do high-purity graphite molds play during VHP of SiC/Al? Enhance Your Composite Material Quality

- How do high-precision molds contribute to Li6PS5Cl electrolyte membrane formation? Achieve Perfect Density and Thickness