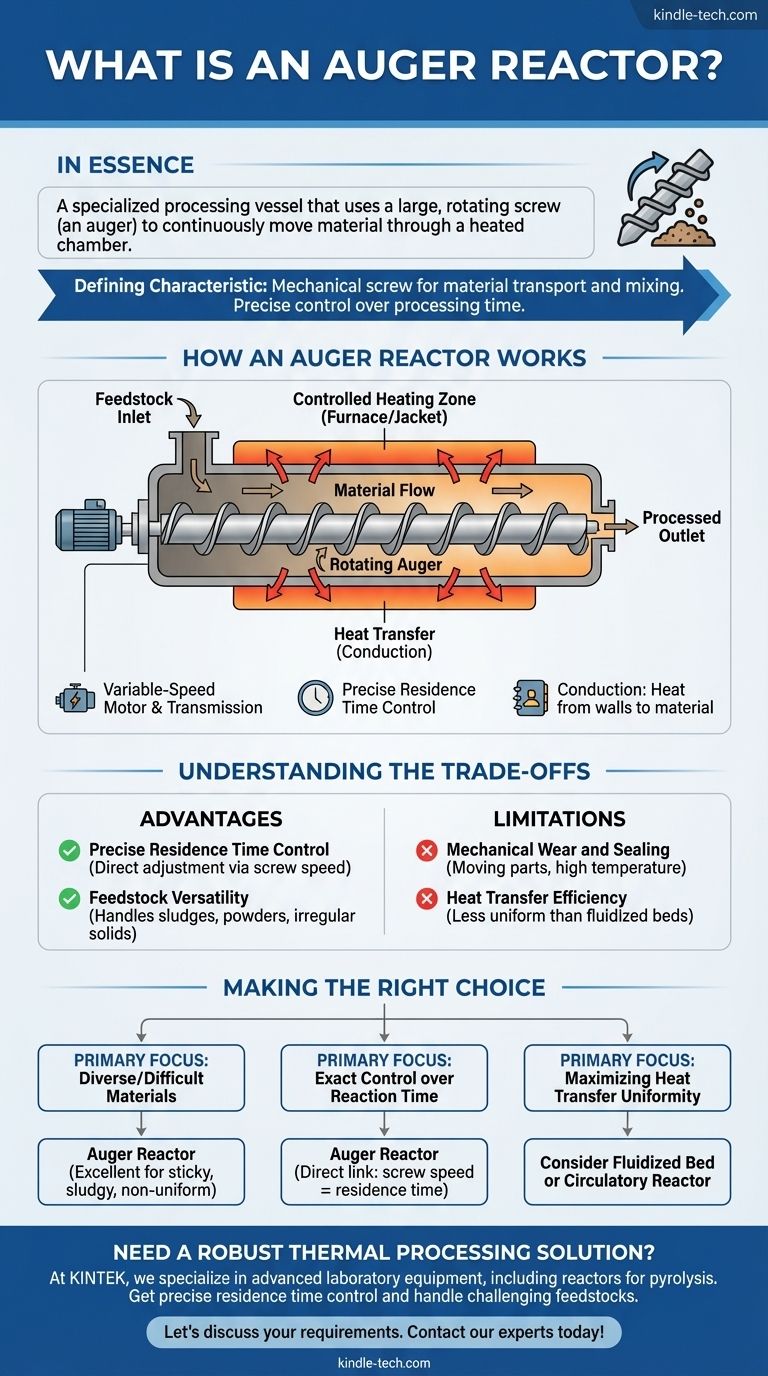

In essence, an auger reactor is a specialized processing vessel that uses a large, rotating screw (an auger) to continuously move material through a heated chamber. This design gives operators precise control over how long the material is processed, as the speed of the screw directly dictates the rate of movement. Its function relies on mechanical conveyance, setting it apart from other reactor types.

The defining characteristic of an auger reactor is its use of a mechanical screw for material transport and mixing. This provides excellent control over processing time and allows it to handle a wide variety of materials, but introduces mechanical complexity compared to fluid-based systems.

How an Auger Reactor Works

An auger reactor's operation is straightforward and centers on its core mechanical components. The design is particularly common in processes like pyrolysis, where a solid feedstock needs to be heated in a controlled atmosphere.

The Central Screw Mechanism

The heart of the reactor is the auger, a helical screw that fits snugly inside a cylindrical or U-shaped trough. This screw is connected to a transmission and a variable-speed motor.

As the motor turns the auger, it pushes the feedstock from the inlet at one end of the reactor towards the outlet at the other, much like an Archimedes' screw moves water.

The Controlled Heating Zone

The entire vessel through which the auger transports the material is the hot zone. This is typically enclosed in an external heating system, such as a furnace or an electric heating jacket.

The material is heated as it is conveyed, causing the desired chemical or physical reaction to occur. The speed of the screw determines the residence time—the exact duration the material spends in this hot zone.

The Heat Transfer Method

Unlike fluidized bed reactors that use hot gas to suspend and heat particles, an auger reactor primarily relies on conduction.

Heat transfers from the hot reactor walls directly to the material particles as they are tumbled and pushed along by the screw. This reliance on mechanical force and pressure for movement and heat transfer is a key differentiator.

Understanding the Trade-offs

No single reactor design is perfect for every application. The mechanical nature of the auger reactor presents a distinct set of advantages and limitations.

Advantage: Precise Residence Time Control

The most significant benefit is the direct control over processing time. By simply adjusting the motor's speed, an operator can precisely increase or decrease how long the material is exposed to heat.

Advantage: Feedstock Versatility

The positive, mechanical force of the screw allows auger reactors to process a wide range of materials. They are effective with sludges, powders, and irregularly shaped feedstocks that might clog or fail to fluidize in other reactor types.

Limitation: Mechanical Wear and Sealing

The primary drawback is mechanical complexity. The rotating screw, bearings, and seals are subject to wear and tear, especially under high temperatures and abrasive conditions.

Maintaining an airtight seal around the rotating shaft is also a critical engineering challenge, particularly in processes that require an oxygen-free environment.

Limitation: Heat Transfer Efficiency

Heat transfer can be less uniform compared to a well-mixed fluidized bed reactor, where every particle is surrounded by hot gas. In an auger, particles closer to the heated wall may reach higher temperatures than those in the center of the screw's path.

Making the Right Choice for Your Goal

Selecting an auger reactor depends entirely on the specific requirements of your process, particularly the nature of your feedstock and the level of control you need.

- If your primary focus is processing diverse or difficult materials: An auger reactor is an excellent choice for feedstocks that are sticky, sludgy, or have non-uniform particle sizes.

- If your primary focus is exact control over reaction time: The direct link between screw speed and residence time makes the auger reactor superior for processes sensitive to duration.

- If your primary focus is maximizing heat transfer uniformity: You may want to consider a fluidized bed or circulatory reactor, which often provides more homogenous heating.

Ultimately, the auger reactor is a robust and highly controllable tool designed for specific material handling challenges.

Summary Table:

| Feature | Description |

|---|---|

| Core Mechanism | Rotating helical screw (auger) conveys material through a heated chamber. |

| Key Advantage | Precise control over material residence time via screw speed adjustment. |

| Ideal For | Processing diverse, difficult materials like sludges, powders, and irregular solids. |

| Heat Transfer | Primarily conduction from heated reactor walls to the material. |

| Main Consideration | Mechanical wear on the screw and seals; less uniform heating than fluidized beds. |

Need a robust thermal processing solution for your specific materials?

At KINTEK, we specialize in designing and supplying advanced laboratory equipment, including reactors tailored for complex processes like pyrolysis. Our expertise ensures you get the right system for precise residence time control and handling challenging feedstocks.

Let's discuss your application requirements and find the optimal solution for your lab. Contact our experts today!

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

People Also Ask

- What is the contribution of a hydrothermal reactor to graded pore construction? Precision Templates for TAS

- How does a high-pressure reactor demonstrate its value in accelerated aging? Predict Catalyst Durability Fast

- What is the role of high-pressure reactors in the study of alloy oxidation? Essential Tools for Supercritical Research

- Why are high-pressure autoclaves essential for preparing bio-based polyamide curing agents from dimeric acid?

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation