In the simplest terms, bio-oil is a dark, liquid fuel produced from the thermal decomposition of biomass, such as wood or agricultural waste. This conversion is achieved through a high-temperature process called pyrolysis, which heats the organic material in an environment without oxygen, causing it to break down into gases that are then cooled and condensed into the final liquid product.

While often called an "oil," it's crucial to understand that bio-oil is not a direct substitute for crude petroleum. It is a raw, complex intermediate product that turns solid biomass into a dense, transportable liquid, but it requires significant processing before it can be used as a conventional fuel.

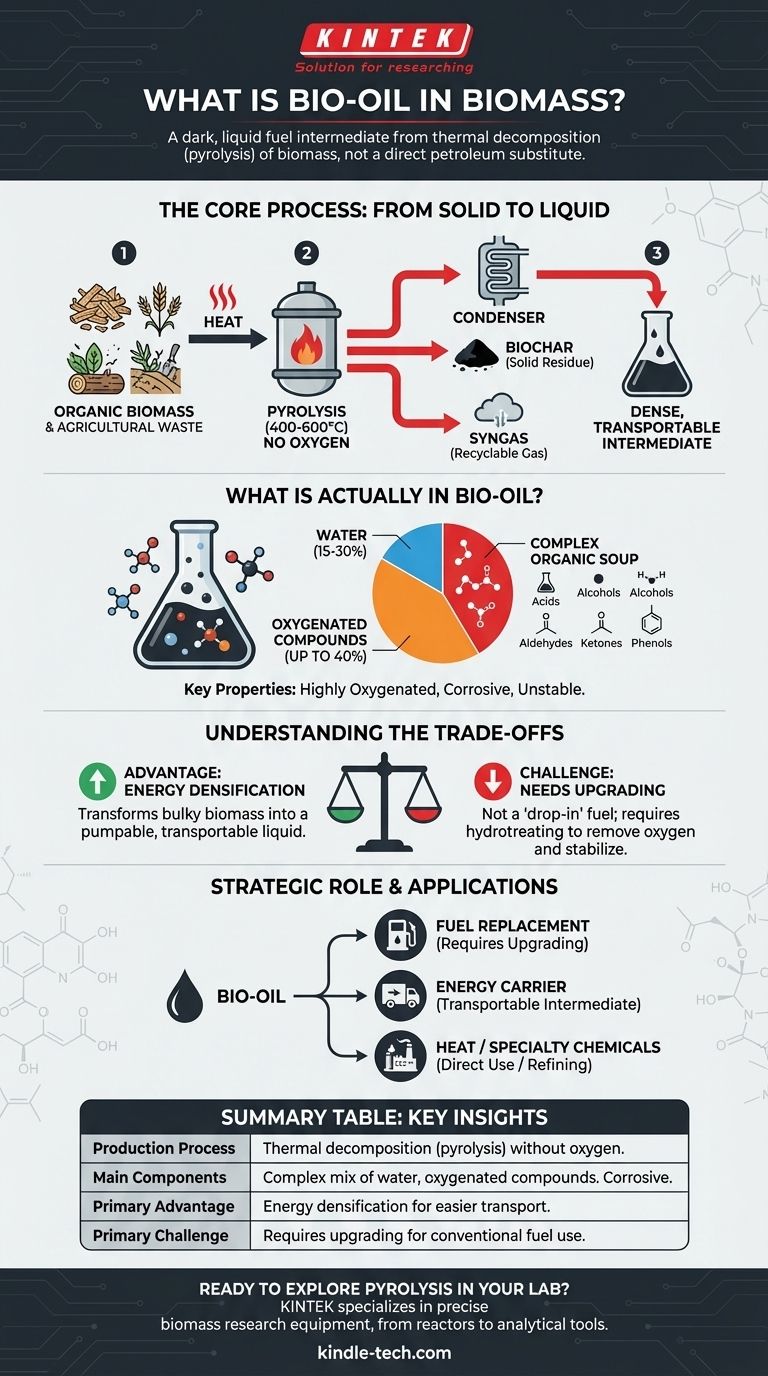

The Core Process: From Solid Biomass to Liquid Fuel

To understand what bio-oil is, you must first understand how it is made. The entire process hinges on heating organic matter in a very specific way to break it down without allowing it to burn.

What is Pyrolysis?

Pyrolysis is the process of thermal decomposition in the absence of oxygen. Think of it as "pressure cooking" biomass at very high temperatures (typically 400-600°C). Because there is no oxygen, the material cannot combust; instead, its complex organic structures break apart into smaller volatile molecules, which form a hot gas.

From Gas to Liquid

Once the biomass has been vaporized, these hot gases are rapidly cooled, or "quenched." This rapid cooling causes most of the gases to condense into a liquid—this liquid is bio-oil.

The Three Products of Pyrolysis

The pyrolysis process doesn't just create bio-oil. It efficiently separates the solid biomass into three distinct products:

- Bio-oil: The condensed liquid fraction, which captures the bulk of the initial energy.

- Biochar: A solid, charcoal-like residue that remains after the volatile gases have been driven off.

- Syngas: A mixture of non-condensable gases (like carbon monoxide and hydrogen) that can be recycled to provide heat for the pyrolysis process itself.

What is Actually in Bio-Oil?

The term "oil" can be misleading. Unlike petroleum crude oil, which is composed almost entirely of hydrocarbons (hydrogen and carbon), bio-oil has a much more complex and challenging chemical profile.

A Complex Chemical Mixture

Bio-oil is an intricate soup of hundreds of different organic compounds. Critically, these compounds are highly oxygenated, meaning they contain a significant amount of oxygen atoms within their molecular structures. This includes acids, alcohols, aldehydes, ketones, and phenols.

Key Properties: Water and Oxygen

Two defining features of raw bio-oil are its high water content (15-30%) and high oxygen content (up to 40%). The water comes directly from the moisture in the original biomass, while the oxygen is a remnant of the cellulose and lignin structures.

Instability and Corrosiveness

The presence of organic acids, particularly acetic acid, makes bio-oil highly corrosive to common metals like carbon steel. Furthermore, the reactive nature of its chemical components means it is unstable and can thicken, polymerize, and age over time, making long-term storage a challenge.

Understanding the Trade-offs

Bio-oil presents a classic engineering trade-off. It solves one major problem but introduces another that must be managed.

The Advantage: Energy Densification

The primary benefit of converting biomass to bio-oil is densification. It transforms bulky, low-density, and difficult-to-handle solid biomass (like wood chips or corn stalks) into a pumpable liquid. This makes the energy far easier to transport and store, decoupling the energy production from its final point of use.

The Challenge: The Need for Upgrading

The main disadvantage is that bio-oil is not a "drop-in" fuel. Its high oxygen content, water content, corrosiveness, and instability prevent it from being used directly in conventional engines or refined in traditional petroleum refineries. It must first go through a secondary process called upgrading (e.g., hydrotreating) to remove oxygen and improve its properties.

Making the Right Choice for Your Goal

Understanding bio-oil's true nature allows you to see its strategic role in the bio-energy landscape. Its value depends entirely on the intended application.

- If your primary focus is creating a direct replacement for gasoline or diesel: View bio-oil as a crucial starting point, not the final product; significant and often costly upgrading is non-negotiable.

- If your primary focus is converting waste biomass into a transportable energy carrier: Bio-oil is an excellent intermediate, efficiently packaging the energy from dispersed, low-value biomass so it can be moved to a central processing facility.

- If your primary focus is producing heat or specialty chemicals: Raw bio-oil can be burned in specially designed industrial furnaces and boilers, or it can be refined to extract valuable bio-based platform chemicals.

Ultimately, bio-oil serves as a vital bridge, converting the potential of raw, solid biomass into a more versatile liquid energy carrier.

Summary Table:

| Property | Description | Key Insight |

|---|---|---|

| Production Process | Thermal decomposition of biomass without oxygen (pyrolysis). | Converts solid biomass into a transportable liquid. |

| Main Components | Complex mixture of water (15-30%) and oxygenated organic compounds. | Highly corrosive and unstable; not a direct petroleum substitute. |

| Primary Advantage | Energy densification for easier transport and storage. | Solves the logistical challenge of bulky biomass. |

| Primary Challenge | Requires upgrading (e.g., hydrotreating) for use as conventional fuel. | Raw bio-oil is an intermediate product, not a final fuel. |

Ready to explore pyrolysis and biomass conversion in your lab?

At KINTEK, we specialize in the precise lab equipment and consumables needed for advanced biomass research, from pyrolysis reactors to analytical tools. Our solutions help you efficiently produce and analyze bio-oil, biochar, and syngas, accelerating your development of sustainable fuels and chemicals.

Contact us today to discuss how our expertise can support your specific laboratory needs and help you achieve your research goals. Get in touch via our contact form.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electrolytic Electrochemical Cell Gas Diffusion Liquid Flow Reaction Cell

People Also Ask

- What are the contaminants in plastic pyrolysis oil? Manage Impurities for Commercial Success

- Why is a high-frequency ultrasonic cleaner necessary for steel substrate preparation? Achieve 100% Coating Adhesion

- What is surface sputtering? A Guide to Precision Thin Film Deposition & Etching

- What is the process of thin film in semiconductor? Build the Layers of Modern Electronics

- Why are high-energy homogenizers required for high-performance microbial biopolymers? Achieving Superior Dispersion

- How heat is transferred differently for each type? Understand Conduction, Convection & Radiation

- What is a rotary vacuum evaporator? A Guide to Gentle & Efficient Solvent Removal

- What are the 3 factors that affect the rate of heat transfer by conduction? Master Thermal Control for Your Lab Equipment