Deposition of diamond films is a process for growing a thin layer of synthetic diamond on the surface of another material, known as a substrate. It primarily uses a technique called Chemical Vapor Deposition (CVD), which involves introducing a carbon-containing gas (like methane) and hydrogen into a chamber. An energy source is then used to break these gases down into reactive atoms that settle on the substrate and arrange themselves into the crystal structure of diamond.

The central challenge in growing diamond isn't creating carbon, but creating a specific chemical environment where the diamond (sp³) atomic structure is far more likely to form and remain stable than the graphite (sp²) structure. This is achieved by using an energy source to generate atomic hydrogen, which acts as a selective "gardener" for the growing film.

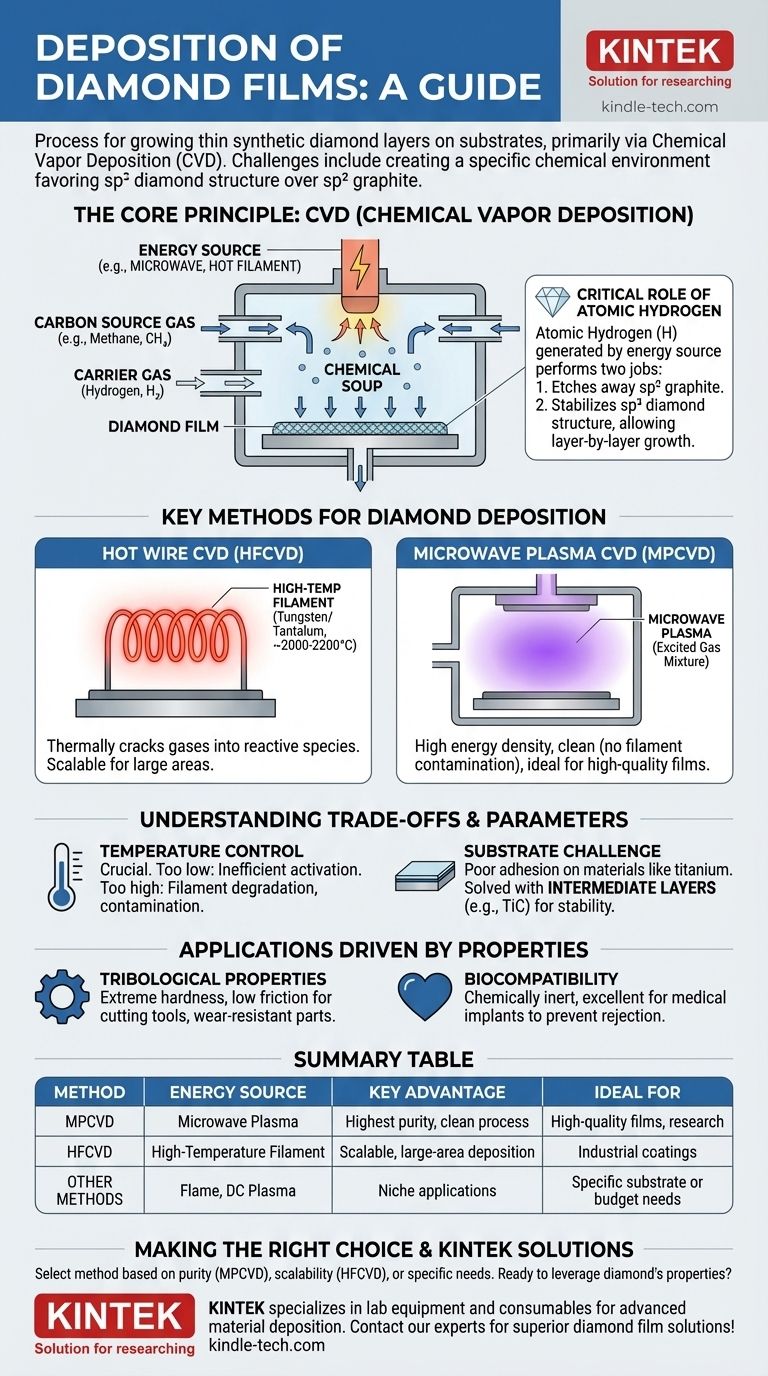

The Core Principle: Chemical Vapor Deposition (CVD)

CVD is the foundation of modern diamond film deposition. It allows for the creation of high-purity diamond at pressures far below one atmosphere, unlike the extreme high-pressure, high-temperature methods used to create bulk industrial diamonds.

How CVD Works for Diamond

The process requires a few key ingredients: a substrate to grow on, a carbon source gas (typically methane, CH₄), a carrier gas (hydrogen, H₂), and a powerful energy source. The energy activates the gases, creating the necessary chemical soup for diamond to form.

The Critical Role of Atomic Hydrogen

Carbon atoms can bond in two primary ways: the sp² configuration (forming flat sheets of graphite) or the sp³ configuration (forming the strong, tetrahedral lattice of diamond). Under normal CVD conditions, graphite forms more easily.

The key to success is atomic hydrogen. The energy source splits stable hydrogen molecules (H₂) into highly reactive single hydrogen atoms (H). This atomic hydrogen performs two critical jobs:

- It preferentially etches away any sp²-bonded graphite that forms on the surface.

- It stabilizes the sp³-bonded diamond structure, allowing it to grow layer by layer.

Key Methods for Diamond Deposition

While the principle is the same, different methods use different energy sources to activate the gases.

Hot Wire CVD (HFCVD)

This method, developed in the early 1980s, uses a high-temperature filament made of tungsten or tantalum. The filament is heated to around 2000-2200°C.

Gases passing over this extremely hot wire are thermally cracked, or "cleaved," into the reactive carbon species and atomic hydrogen needed for diamond growth.

Microwave Plasma CVD (MPCVD)

This is now a widely preferred method. It uses microwaves to excite the gas mixture into a plasma, which is an energized state of matter containing ions and electrons.

This plasma provides a very high energy density and is exceptionally clean, as there is no hot filament that could potentially contaminate the diamond film. This makes it ideal for producing high-quality films.

Other Established Methods

While HFCVD and MPCVD are common, other techniques exist, including Flame Combustion CVD and DC Plasma-Assisted CVD. Each uses a different mechanism to generate the necessary energy and reactive species.

Understanding the Trade-offs and Critical Parameters

Depositing high-quality diamond film is a precise science where small changes in process variables can have significant effects.

The Importance of Temperature

Temperature is arguably the most crucial parameter. In Hot Wire CVD, the filament temperature must be meticulously controlled.

If the temperature is too low, the gases won't activate efficiently, hindering or preventing diamond formation. If it's too high, the filament can degrade and contaminate the substrate and the growing film.

The Substrate Challenge

Diamond does not easily grow on every material. For certain substrates, like titanium, a direct deposition can fail due to poor adhesion or unwanted chemical reactions.

To solve this, researchers use intermediate layers. For example, a thin layer of titanium carbide (TiC) can be deposited first, creating a more stable and receptive surface for the diamond film to adhere to.

Applications Driven by Properties

The reason for this complex process is diamond's exceptional properties. The films provide extreme hardness and low friction (tribological properties) for cutting tools and wear-resistant parts.

Furthermore, diamond is highly biocompatible and chemically inert, making it an excellent coating for medical implants to prevent rejection by the body.

Making the Right Choice for Your Goal

Selecting a deposition method depends entirely on the desired outcome, balancing film quality, cost, and the specific application.

- If your primary focus is the highest purity and film quality: MPCVD is often the ideal choice due to its clean, filament-free, and high-energy plasma environment.

- If your primary focus is scalable, large-area deposition: HFCVD is a robust and well-understood method, but requires precise control over temperature to avoid contamination.

- If your primary focus is coating a chemically reactive material: You must investigate and implement a suitable intermediate buffer layer to ensure proper film adhesion and stability.

Ultimately, successful diamond film deposition hinges on precisely controlling the chemical environment to favor the growth of diamond's unique atomic structure.

Summary Table:

| Method | Energy Source | Key Advantage | Ideal For |

|---|---|---|---|

| Microwave Plasma CVD (MPCVD) | Microwave Plasma | Highest purity, clean process | High-quality films, research |

| Hot Wire CVD (HFCVD) | High-Temperature Filament | Scalable, large-area deposition | Industrial coatings |

| Other Methods | Flame, DC Plasma | Niche applications | Specific substrate or budget needs |

Ready to leverage diamond's extreme hardness and biocompatibility in your lab? KINTEK specializes in lab equipment and consumables for advanced material deposition. Our expertise can help you select the right CVD method and parameters to achieve superior diamond films for your specific application—whether it's for cutting tools, medical devices, or research. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance