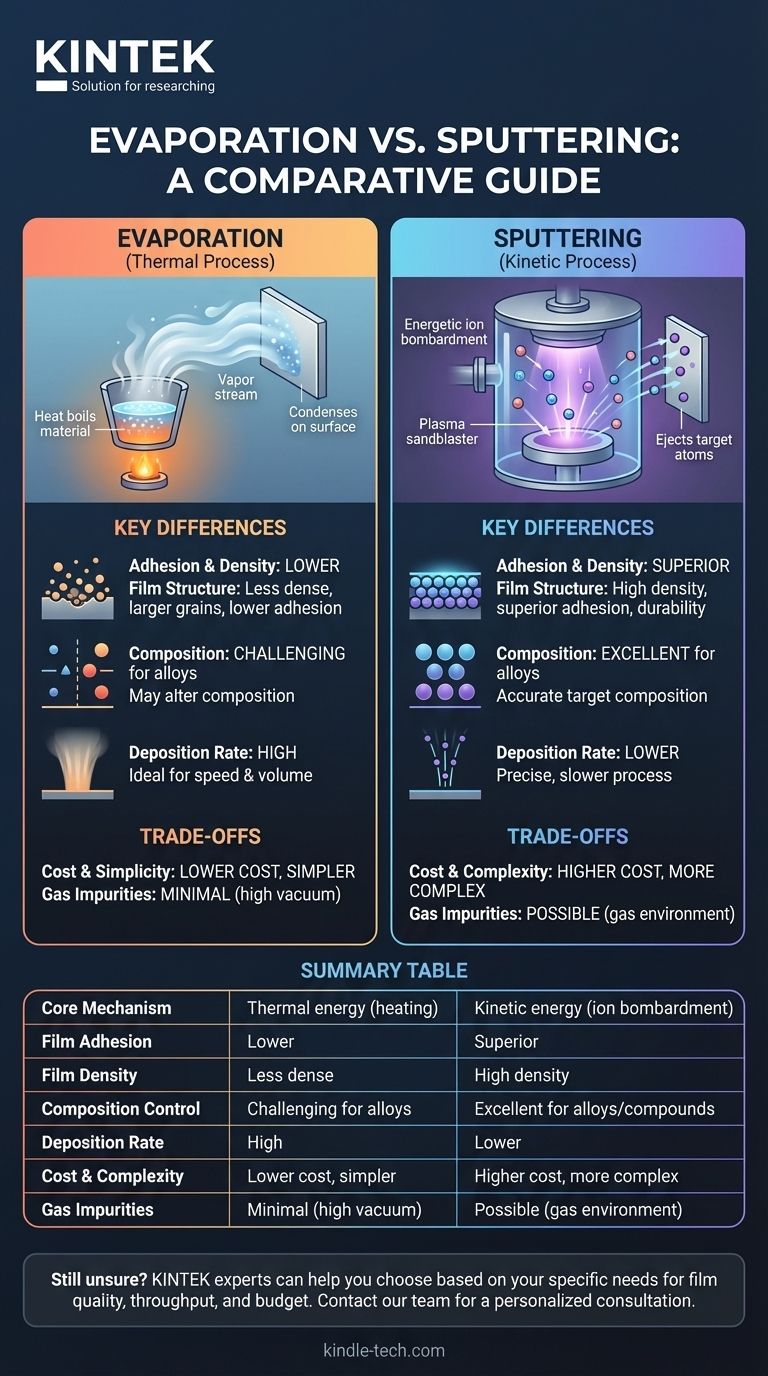

At a fundamental level, the difference between evaporation and sputtering lies in how atoms are liberated from a source material to create a thin film. Evaporation uses heat to boil a material into a vapor that condenses onto a surface, much like steam fogging a cold mirror. Sputtering, in contrast, uses energetic ion bombardment to physically knock atoms off a target material, like a microscopic sandblaster.

While both are physical vapor deposition (PVD) methods performed in a vacuum, the choice between them comes down to a critical trade-off: evaporation is typically faster and more cost-effective, while sputtering provides superior film quality, adhesion, and compositional control at the cost of speed and complexity.

The Core Mechanism: Heat vs. Impact

Understanding how each process generates a coating material is the key to grasping their respective strengths and weaknesses. They are fundamentally different approaches to achieving the same goal.

How Evaporation Works: The Boiling Analogy

Evaporation is a thermal process. A source material, or "charge," is placed in a high-vacuum chamber and heated until it reaches its vaporization temperature.

This creates a robust vapor stream that travels in a line-of-sight path and condenses on a cooler substrate, forming the thin film. The energy of the deposited particles is relatively low, determined purely by the thermal energy of the process.

How Sputtering Works: The Plasma Sandblaster

Sputtering is a kinetic process. It begins by introducing a low-pressure inert gas (typically Argon) into a vacuum chamber to create a plasma.

An electric field accelerates ions from this plasma, causing them to collide with the source material, known as the target. These high-energy impacts physically eject, or "sputter," individual atoms from the target. These ejected atoms have significantly higher kinetic energy and travel to coat the substrate.

Key Differences in Film Properties

The difference in energy—low thermal energy for evaporation versus high kinetic energy for sputtering—directly translates into major differences in the final film's characteristics.

Film Adhesion and Density

Sputtered atoms arrive at the substrate with high energy, embedding themselves slightly into the surface and creating a dense, tightly packed film. This results in superior adhesion and durability.

Evaporated atoms land more gently, leading to films that are typically less dense, have a larger grain structure, and exhibit lower adhesion to the substrate.

Film Homogeneity and Composition

Sputtering excels at depositing complex materials like alloys and compounds. Because the "sandblasting" process ejects atoms non-selectively, the composition of the deposited film remains very close to that of the target.

Evaporation can struggle with alloys where different elements have different vapor pressures (boiling points). The element with the higher vapor pressure will evaporate more readily, potentially altering the final film's composition from that of the original source.

Deposition Rate and Speed

Evaporation generally offers a much higher deposition rate. The ability to generate a dense vapor stream allows for thicker films to be deposited in shorter run times, making it suitable for high-volume production.

Sputtering is a slower, more deliberate process. Ejecting atoms one by one results in a lower deposition rate, making it less ideal for applications where speed is the primary concern.

Understanding the Trade-offs

Neither method is universally superior; they are tools designed for different tasks. Choosing the wrong one can lead to poor film quality or unnecessary costs.

The Cost and Simplicity Factor

Evaporation systems are often simpler in design and therefore more cost-effective to build and operate. This, combined with their high deposition rates, makes them an economical choice for many applications.

Sputtering systems, requiring high-voltage power supplies, gas handling, and often magnetrons to enhance the process, are generally more complex and expensive.

The Control and Precision Factor

Sputtering offers a much higher degree of process control. Parameters like gas pressure and power can be fine-tuned to manipulate film properties such as grain size, internal stress, and density.

This makes sputtering the preferred method for applications demanding high precision and repeatability, such as in the manufacturing of optical filters, semiconductors, and medical devices.

The Environmental and Gas Factor

Sputtering operates in a low-pressure gas environment, which means some of the process gas can become trapped in the growing film as an impurity. This is referred to as absorbed gas.

Evaporation occurs in a high vacuum, resulting in purer films with fewer gaseous inclusions, which can be critical for certain electronic or optical applications.

Making the Right Choice for Your Application

Your final decision must be guided by the specific requirements of your project.

- If your primary focus is speed and cost-efficiency for simple coatings: Choose thermal evaporation, especially for single-element metals.

- If your primary focus is superior film adhesion, density, and durability: Choose sputtering, as the high-energy deposition creates a stronger, more robust film.

- If you are depositing complex alloys or compounds: Choose sputtering to ensure the film's composition accurately reflects the source target.

- If you require the absolute highest film purity with minimal gas contamination: Evaporation in a high-vacuum environment is the better option.

Understanding this core distinction between thermal energy and kinetic energy empowers you to select the precise tool for your thin-film deposition needs.

Summary Table:

| Feature | Evaporation | Sputtering |

|---|---|---|

| Core Mechanism | Thermal energy (heating) | Kinetic energy (ion bombardment) |

| Film Adhesion | Lower | Superior |

| Film Density | Less dense | High density |

| Composition Control | Challenging for alloys | Excellent for alloys/compounds |

| Deposition Rate | High | Lower |

| Cost & Complexity | Lower cost, simpler | Higher cost, more complex |

| Gas Impurities | Minimal (high vacuum) | Possible (gas environment) |

Still unsure which PVD method is right for your application? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you choose between evaporation and sputtering systems based on your specific requirements for film quality, throughput, and budget.

Contact our team today for a personalized consultation and discover how our solutions can enhance your thin-film deposition processes.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- How plasma is created in magnetron sputtering? The Engine for High-Quality Thin-Film Deposition

- What are the risks of biomass boilers? Understanding the Environmental and Operational Trade-offs

- What are some ethical issues with diamond mining? Uncover the Hidden Costs of Your Gemstone

- What is high temperature sintering of ceramics? Transform Powder into Dense, High-Performance Components

- What are the advantages of RF magnetron sputtering? Achieve Superior Thin Film Deposition for Insulating Materials

- What is calcination? A Guide to High-Temperature Purification and Transformation

- What are some ways you can prevent injury when dealing with hot substances and objects? A Proactive Framework for Thermal Safety

- What roles do the heating unit and jacketed system play in solar collector simulation? Optimize Your Thermal Research