In material science and manufacturing, film uniformity is a measure of how consistent the thickness of a deposited thin film is across a given surface. This means that for a highly uniform film, the thickness measured at any point on a substrate, such as a semiconductor wafer or an optical lens, is nearly identical to the thickness measured at any other point. It is a fundamental indicator of process control and quality.

Achieving high film uniformity is the foundation of device reliability and performance. While seemingly a simple metric, minor variations in thickness can lead to significant failures in the final product, from unpredictable semiconductor behavior to flawed optical coatings.

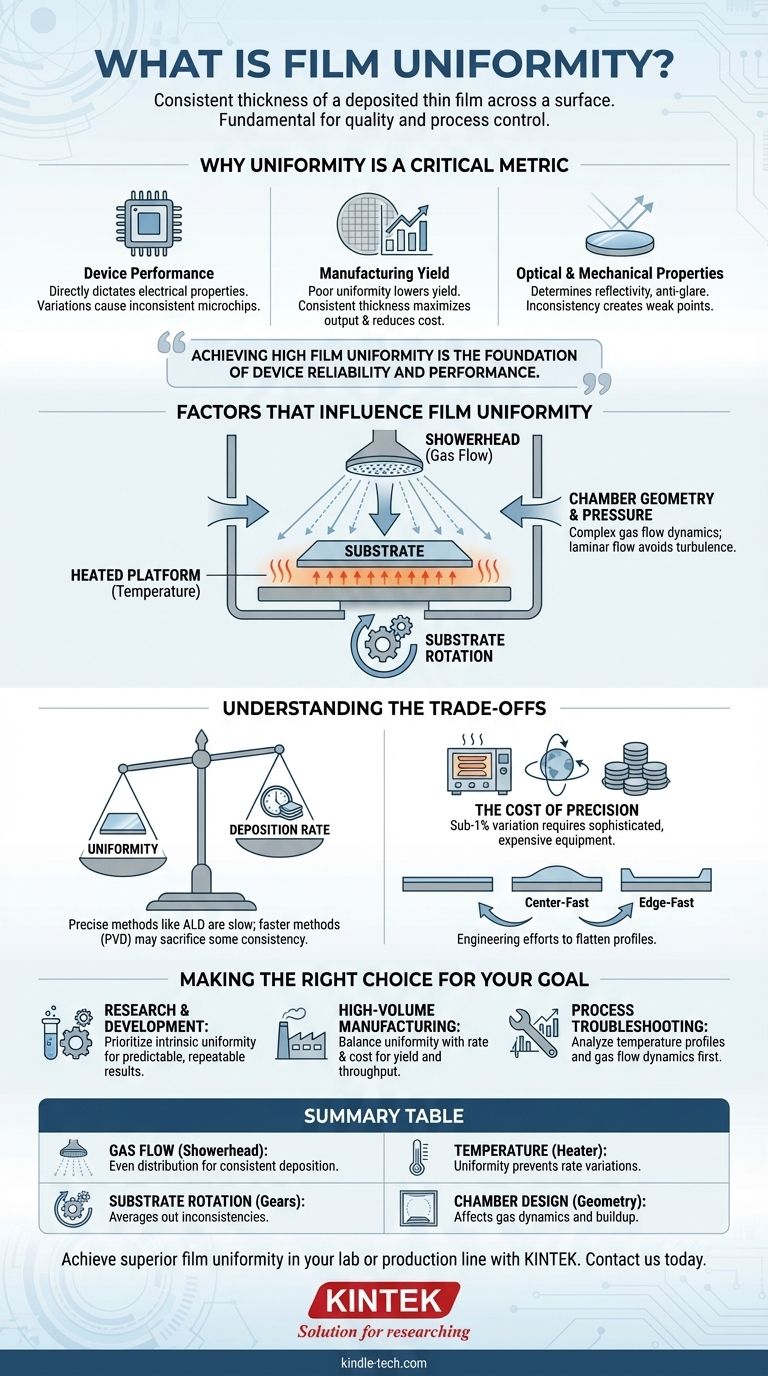

Why Uniformity is a Critical Metric

The demand for uniformity is not academic; it has direct, tangible consequences on the final product's functionality and economic viability.

Impact on Device Performance

In semiconductor manufacturing, the thickness of a deposited layer dictates its electrical properties, such as capacitance and resistance. If a film's thickness varies across a wafer, the resulting microchips will have inconsistent performance, rendering many of them unusable.

Ensuring Manufacturing Yield

Poor uniformity directly translates to lower yield—the percentage of usable devices from a single wafer or production batch. By ensuring every device on the substrate is built with layers of the correct thickness, manufacturers maximize output and reduce the cost per unit.

Optical and Mechanical Properties

The principle extends beyond electronics. For optical coatings on lenses, thickness determines properties like reflectivity and anti-glare performance. For protective hard coatings on tools, inconsistent thickness can create weak points that lead to premature failure.

Factors That Influence Film Uniformity

Achieving a uniform film is an engineering challenge that involves controlling multiple variables within the deposition chamber.

Process Gas and Material Flow

In chemical vapor deposition (CVD) processes, uniformity is heavily dependent on the even distribution of precursor gases. This is often managed with a "showerhead," a precisely engineered component that releases gases evenly across the substrate, much like a high-end sprinkler ensuring even coverage on a lawn.

Substrate Temperature

The rate at which chemical reactions occur or materials condense is highly sensitive to temperature. Maintaining a perfectly consistent temperature across the entire surface of the substrate is crucial for ensuring a uniform deposition rate.

Substrate Rotation

Many deposition systems rotate the substrates during the process. This simple mechanical action helps average out any inconsistencies in the flow of material from the source, significantly improving the final film's uniformity.

Chamber Geometry and Pressure

The physical shape of the deposition chamber and the system's operating pressure create complex gas flow dynamics. Engineers carefully design chambers and tune pressure levels to promote a stable, laminar flow of material toward the substrate, avoiding turbulence that can cause uneven buildup.

Understanding the Trade-offs

Pursuing perfect uniformity often involves balancing competing priorities. There is no single "best" solution, only the right solution for a specific application.

Uniformity vs. Deposition Rate

Some of the most precise deposition techniques, like Atomic Layer Deposition (ALD), offer exceptional uniformity but are inherently slow. Faster methods, such as certain types of Physical Vapor Deposition (PVD), may increase throughput at the cost of some film consistency.

The Cost of Precision

Achieving sub-1% thickness variation requires highly sophisticated and expensive equipment. Advanced showerheads, multi-zone heating systems, and planetary substrate rotation mechanisms add significant capital and operational costs to the manufacturing process.

Center-Fast vs. Edge-Fast Profiles

A common challenge is managing deposition profiles that are naturally thicker in the middle ("center-fast") or at the edges ("edge-fast"). A great deal of process engineering is dedicated to tuning gas flows, temperatures, and chamber geometry to flatten this profile and achieve uniformity.

Making the Right Choice for Your Goal

Your approach to film uniformity should be dictated by your specific objective, whether in a research lab or on a factory floor.

- If your primary focus is research and development: Prioritize deposition methods that offer the highest intrinsic uniformity, even if they are slower, to achieve predictable and repeatable results.

- If your primary focus is high-volume manufacturing: Balance the need for acceptable uniformity with deposition rate and equipment cost to optimize manufacturing yield and throughput.

- If your primary focus is process troubleshooting: Begin by analyzing temperature profiles and gas flow dynamics, as these variables are the most common sources of uniformity degradation.

Mastering film uniformity is not just about controlling thickness; it is about controlling the fundamental performance and reliability of your final product.

Summary Table:

| Aspect | Impact on Uniformity |

|---|---|

| Gas Flow | Even distribution via showerheads ensures consistent deposition. |

| Temperature | Uniform substrate temperature prevents rate variations. |

| Substrate Rotation | Averages out inconsistencies for improved thickness control. |

| Chamber Design | Geometry and pressure affect gas dynamics and material buildup. |

Achieve superior film uniformity in your lab or production line with KINTEK.

Whether you are developing next-generation semiconductors or precision optical coatings, consistent film thickness is non-negotiable for device performance and yield. KINTEK specializes in high-quality lab equipment and consumables designed to deliver precise, repeatable deposition results.

We provide solutions tailored to your needs:

- Research & Development: Access deposition systems with exceptional uniformity for predictable, reliable outcomes.

- High-Volume Manufacturing: Balance uniformity with throughput using cost-effective, high-yield equipment.

Let us help you optimize your process control and maximize your output. Contact KINTEK today to discuss how our expertise in lab equipment can enhance your film deposition quality and efficiency.

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- What is the powder sintering process? A Guide to Net-Shape Manufacturing

- What is the process used in semiconductor device fabrication? A Step-by-Step Guide to Microchip Manufacturing

- What is the alternative to filter press? Compare Continuous Dewatering Technologies

- What apparatus is used for drying specimens? Select the Right Tool to Preserve Your Sample Integrity

- What are the components of sintering? Master the 4-Step Process for Stronger Materials

- What are the 3 factors that affect the rate of heat transfer by conduction? Master Thermal Control for Your Lab Equipment

- What are the components of a pyrolysis reactor? A Guide to Core Parts & Designs

- How does a benchtop orbital shaker facilitate the production of reducing sugars? Boost Cellulose Hydrolysis Yields