At its core, a laboratory crusher is a device designed to forcefully reduce large, solid samples into smaller, more manageable pieces or a coarse powder. Often called a laboratory jaw crusher, its primary function is to serve as the initial step in sample preparation, breaking down materials like rocks, ores, or crystals for subsequent analysis or processing.

The true purpose of a laboratory crusher is not merely to break things, but to create a uniform, representative sample from a larger, heterogeneous source. This initial size reduction is a non-negotiable first step for achieving accurate and repeatable results in many analytical techniques.

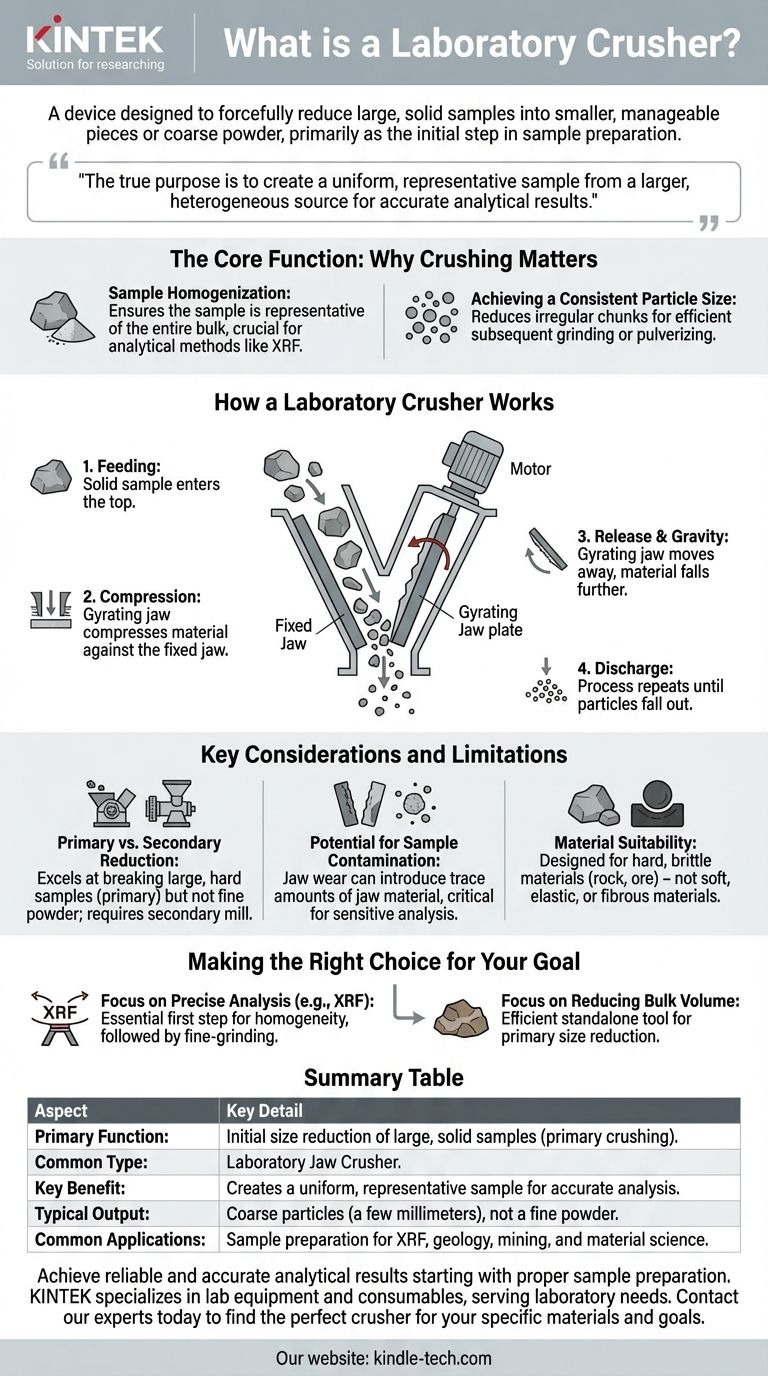

The Core Function: Why Crushing Matters

A laboratory crusher bridges the gap between a raw, bulk sample collected in the field and a refined material ready for scientific analysis.

The Goal: Sample Homogenization

For analytical methods like X-Ray Fluorescence (XRF), the sample presented to the instrument must be perfectly homogenous. A large rock, for example, has different mineral compositions in different areas.

By crushing the entire sample into smaller particles, you can mix them together to create a material that represents the average composition of the original source. This ensures the small amount being analyzed is truly representative of the whole.

Achieving a Consistent Particle Size

Accurate analysis requires a consistent particle size. A crusher reduces large, irregular chunks into a more uniform output, which is crucial for ensuring that subsequent grinding or pulverizing steps are efficient and effective.

How a Laboratory Crusher Works

The most common design is the jaw crusher, which operates on a simple but powerful mechanical principle.

The Jaw Crusher Mechanism

A lab crusher uses two heavy plates, known as jaws, arranged in a V-shape or funnel.

- One jaw is fixed and stationary.

- The other is a gyrating jaw that moves back and forth in a rocking motion, driven by a motor.

The space between the jaws is wider at the top, where the material is fed, and narrower at the bottom, where the crushed material is discharged.

The Crushing Process

The process is a continuous cycle of compression and gravity.

- Feeding: The solid sample is dropped into the wide opening at the top of the jaws.

- Compression: The gyrating jaw moves toward the fixed jaw, crushing the material caught between them.

- Release & Gravity: The gyrating jaw moves away, allowing the now smaller pieces to fall further down into the narrowing gap.

- Discharge: This process repeats until the particles are small enough to fall out of the narrow discharge opening at the bottom.

Key Considerations and Limitations

While essential, a laboratory crusher is not a universal solution for all sample preparation needs. Understanding its limitations is critical for proper use.

Primary vs. Secondary Reduction

A jaw crusher is a tool for primary reduction. It excels at breaking large, hard samples (e.g., several centimeters in diameter) down to a few millimeters.

It does not, however, typically produce the fine powder (measured in microns) required for direct analysis. For that, a secondary pulverizer or mill is almost always necessary to finish the job.

Potential for Sample Contamination

The crusher's jaws are made of extremely hard materials, such as manganese steel or tungsten carbide, to withstand immense force. Over time, these plates can wear.

This wear can introduce trace amounts of the jaw material into your sample. For highly sensitive elemental analysis, this contamination can be a significant source of error and must be accounted for.

Material Suitability

Jaw crushers are designed for hard, brittle materials like rock, ore, and minerals. They are not suitable for soft, elastic, or fibrous materials that may deform or jam the mechanism rather than shatter.

Making the Right Choice for Your Goal

The use of a laboratory crusher must align with your final objective.

- If your primary focus is preparing samples for precise chemical analysis (like XRF): A lab crusher is the essential first step to ensure homogeneity, but you must follow it with a fine-grinding pulverizer.

- If your primary focus is simply reducing the bulk volume of hard materials (like ore or rubble): A jaw crusher is an efficient and robust standalone tool for primary size reduction.

Ultimately, viewing the crusher as the foundational step in a multi-stage sample preparation workflow is the key to achieving reliable and accurate results.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Function | Initial size reduction of large, solid samples (primary crushing). |

| Common Type | Laboratory Jaw Crusher. |

| Key Benefit | Creates a uniform, representative sample for accurate analysis. |

| Typical Output | Coarse particles (a few millimeters), not a fine powder. |

| Common Applications | Sample preparation for XRF, geology, mining, and material science. |

Achieve reliable and accurate analytical results starting with proper sample preparation. KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our range of robust laboratory crushers is designed to deliver the consistent, homogeneous samples your analysis depends on. Contact our experts today to find the perfect crusher for your specific materials and goals.

Visual Guide

Related Products

- Laboratory Jaw Crusher

- Sealed Jaw Crusher High Efficiency Environmental Protection Safe and Reliable

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

- Powerful Plastic Crusher Machine

- Laboratory Single Horizontal Jar Mill

People Also Ask

- Why are specialized crushing and separation systems essential for the recovery of recycled antimony from batteries?

- What is the function of crushing and grinding equipment? Key for All-Waste Composite Prep

- What is the primary function of a crushing system? Optimize Rice Husk Fractionation with Precise Size Reduction

- What is the role of crushing and sieving systems in peanut shell pretreatment? Optimize Your Levulinic Acid Production

- Why are laboratory crushing and sieving systems critical for biomass research? Maximize Reaction Precision Today

- What is the primary purpose of using an industrial-grade grinder for flax straw? Optimize Biomass Pretreatment Now

- What is the purpose of using crushing and sieving systems? Optimize Ni/AlCeO3 Catalyst Pretreatment

- What is the role of mechanical crushing equipment in the pretreatment of Salix biomass? Enhance Your Biogas Yield