Mold maintenance is not simply a repair task; it is a proactive and systematic discipline for preserving the condition, performance, and lifespan of an injection mold. This comprehensive strategy involves scheduled cleaning, inspection, measurement, and component replacement to ensure consistent part quality, minimize production downtime, and protect the significant capital investment the tool represents.

Viewing mold maintenance as a mere cost center is a fundamental misunderstanding. It is a critical investment in manufacturing consistency, product quality, and long-term profitability that prevents catastrophic failures and protects your most valuable production assets.

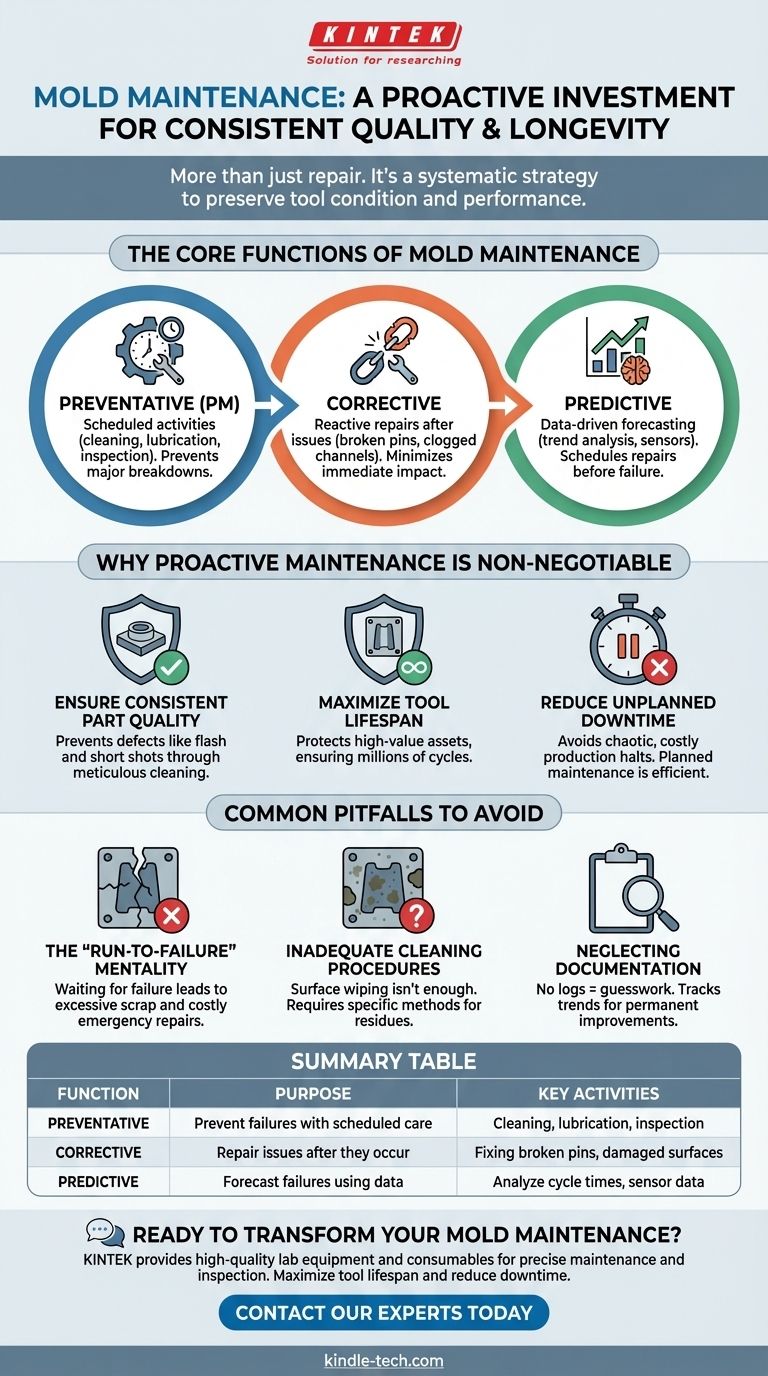

The Core Functions of Mold Maintenance

Effective maintenance programs are built on a tiered approach, moving from reactive fixes to proactive and even predictive actions. Understanding these functions is the first step toward building a reliable manufacturing process.

Preventative Maintenance (PM): The Foundation

Preventative Maintenance is the bedrock of any successful tooling strategy. It involves scheduled activities performed at predetermined intervals, such as cycle counts or hours of operation.

These tasks include thorough cleaning of cavities and vents, lubrication of moving components, and inspection for wear on critical surfaces. Think of this as the scheduled oil changes for your car—it is the essential care required to prevent major, unexpected breakdowns.

Corrective Maintenance: Responding to Issues

Corrective maintenance is the act of repairing a mold after a problem has been identified. This is a reactive process that addresses issues like a broken ejector pin, a damaged parting line, or a clogged water channel.

While necessary, an over-reliance on corrective maintenance is a sign of a weak preventative program. The goal is to minimize the need for these unscheduled, and often costly, interventions.

Predictive Maintenance: The Data-Driven Goal

This is the most advanced stage of maintenance. It uses production data—such as cycle times, part quality measurements, and in-mold sensor readings—to predict when a component is likely to fail before it actually does.

By analyzing trends, a team can schedule a repair during planned downtime, completely avoiding the disruption and scrap caused by an in-process failure.

Why Proactive Maintenance is Non-Negotiable

Ignoring mold maintenance introduces significant and unnecessary risks to your entire operation. A proactive program is a direct investment in performance and stability.

Ensuring Consistent Part Quality

The mold is the single biggest factor in the final quality of a plastic part. Contamination, residue buildup, blocked gas vents, or worn surfaces directly lead to defects like flash, short shots, burns, and dimensional inaccuracies.

Consistent, meticulous cleaning and inspection are the only ways to guarantee that the 100,000th part is identical to the first.

Maximizing Tool Lifespan

Injection molds are high-value capital assets, often costing tens or even hundreds of thousands of dollars. Proper maintenance is the key to maximizing the return on this investment.

Allowing wear and damage to accumulate can lead to irreparable harm, drastically shortening a tool's productive life. Regular care protects the steel and precision components, ensuring the mold runs millions of cycles as intended.

Reducing Unplanned Downtime

There are two types of downtime: planned and unplanned. Planned downtime for preventative maintenance is controlled, scheduled, and efficient.

Unplanned downtime from a catastrophic mold failure is the opposite. It is chaotic, costly, and brings production to a grinding halt, wasting machine time, operator labor, and potentially causing collateral damage to the press itself.

Common Pitfalls to Avoid

Many organizations struggle with mold maintenance because they fall into common traps that treat tooling as a disposable item rather than a critical asset.

The "Run-to-Failure" Mentality

The most common and damaging mistake is to only service a mold when it stops producing acceptable parts. This "if it ain't broke, don't fix it" approach ignores the hidden costs of degraded performance.

It guarantees you will suffer from excessive scrap rates, reduced cycle times, and eventually face an emergency repair that is far more expensive than any scheduled PM.

Inadequate Cleaning Procedures

Simply wiping down a mold surface is not sufficient. Effective cleaning must address hard-to-remove residues from outgassing, mineral deposits in cooling channels, and microscopic debris in vents.

Using the wrong methods or solvents can damage delicate surface finishes. Proper maintenance requires specific techniques, such as ultrasonic cleaning, dry-ice blasting, or specialized chemical agents, matched to the tool's needs.

Neglecting Documentation

A maintenance program without documentation is based on guesswork. A detailed log for each mold is critical for tracking repairs, identifying recurring issues, and understanding the tool's total cost of ownership.

This data allows you to spot trends—like a specific pin that wears out prematurely—and make permanent design or process improvements rather than just repeating the same repair.

How to Apply This to Your Goal

Your approach to mold maintenance should directly align with your operational priorities and the complexity of your tooling.

- If your primary focus is maximizing production uptime: Prioritize a robust preventative maintenance (PM) schedule based on cycle counts to catch wear-and-tear issues before they can stop the press.

- If your primary focus is pristine part quality: Emphasize meticulous in-press and bench-level cleaning procedures, paying special attention to vents, parting lines, and cosmetic surfaces.

- If your primary focus is long-term asset management: Implement detailed documentation for every tool and plan for major overhauls to fully maximize the operational lifespan of your high-cost molds.

Ultimately, a disciplined maintenance program transforms your tooling from a potential liability into a predictable, high-performance asset.

Summary Table:

| Function | Purpose | Key Activities |

|---|---|---|

| Preventative Maintenance (PM) | Prevent failures with scheduled care | Cleaning, lubrication, inspection based on cycle counts |

| Corrective Maintenance | Repair issues after they occur | Fixing broken pins, damaged surfaces, clogged channels |

| Predictive Maintenance | Forecast failures using data | Analyze cycle times, part quality, sensor data to schedule repairs |

Ready to transform your mold maintenance from a cost center into a performance asset? At KINTEK, we specialize in providing high-quality lab equipment and consumables that support precise maintenance and inspection processes. Whether you need reliable tools for cleaning, measurement, or data analysis to implement a proactive maintenance strategy, our solutions are designed to help you maximize tool lifespan, ensure consistent part quality, and reduce costly downtime. Contact our experts today to learn how we can support your laboratory and manufacturing needs!

Visual Guide

Related Products

- CVD Diamond Dressing Tools for Precision Applications

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Custom PTFE Teflon Parts Manufacturer for PTFE Containers

- Lab Sterile Slapping Type Homogenizer for Tissue Mashing and Dispersing

- Desktop Fast High Pressure Laboratory Autoclave Sterilizer 16L 24L for Lab Use

People Also Ask

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- What are some ethical issues with diamond mining? Uncover the Hidden Costs of Your Gemstone

- What is the application of diamond coating? Solve Complex Wear, Heat, and Corrosion Problems

- What are diamond coated tools used for? Conquer Abrasive Materials with Superior Tool Life

- What are the advantages of the CVD diamond growing process compared to the HPHT process? Master Precision & Efficiency