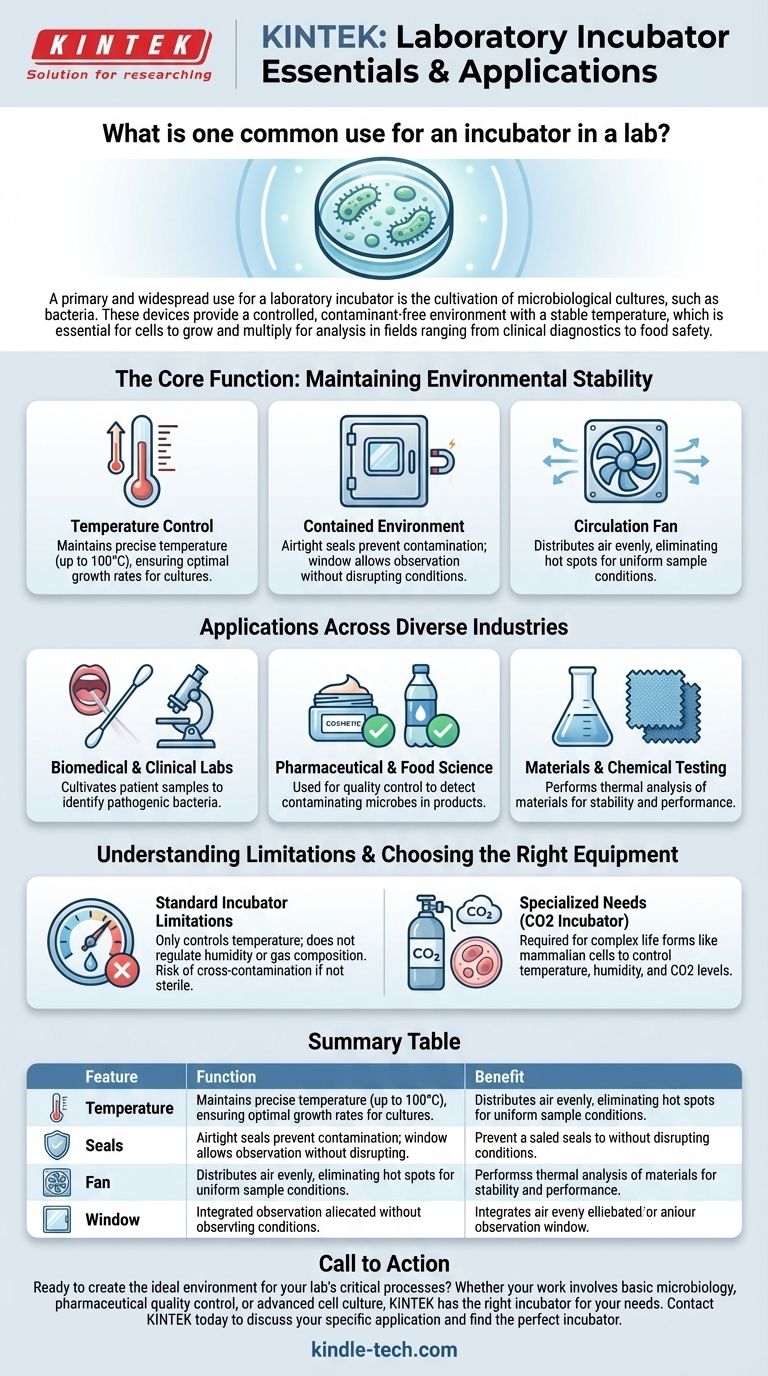

A primary and widespread use for a laboratory incubator is the cultivation of microbiological cultures, such as bacteria. These devices provide a controlled, contaminant-free environment with a stable temperature, which is essential for cells to grow and multiply for analysis in fields ranging from clinical diagnostics to food safety.

At its core, a laboratory incubator is an environmental control chamber. Its fundamental purpose is to remove external variables like fluctuating temperatures, allowing sensitive biological or chemical processes to occur under consistent, repeatable conditions.

The Core Function: Maintaining Environmental Stability

An incubator's value comes from its ability to create and hold a specific environment that is separate from the ambient conditions of the laboratory. This is achieved through several key design features.

The Importance of Temperature Control

Nearly all biological processes are temperature-dependent. The growth of bacteria, for example, is a series of enzymatic chemical reactions that operate most efficiently within a narrow temperature range.

An incubator uses a heating element and a thermostat to maintain a precise temperature, often up to 100°C (212°F), ensuring that cellular growth or a chemical reaction proceeds at a predictable and optimal rate.

Creating a Contained, Uniform Environment

To maintain stability, the internal chamber must be isolated. Magnetic door seals create an airtight environment, preventing temperature fluctuations and keeping airborne contaminants out.

An integrated window allows for the observation of samples without opening the door, which would disrupt the internal temperature and atmosphere.

Furthermore, a circulation fan is critical for ensuring temperature uniformity throughout the chamber, preventing "hot spots" and ensuring all samples are exposed to the exact same conditions.

Applications Across Diverse Industries

While growing bacterial cultures is a foundational use, the principle of environmental control makes incubators indispensable in a vast array of technical fields.

In Biomedical and Clinical Labs

In a clinical setting, a sample from a patient (e.g., a throat swab) is placed on a nutrient medium and put into an incubator. If pathogenic bacteria are present, they will multiply into a visible colony, allowing for identification and diagnosis.

In Pharmaceutical and Food Science

Manufacturers use incubators for quality control. A sample of a product, from cosmetics to beverages, can be incubated to see if any contaminating microbes grow, ensuring the product is safe for consumers.

In Materials and Chemical Testing

The function extends beyond biology. Incubators are used for thermal analysis of materials like polymers, textiles, and construction components to test their stability and performance under specific heat conditions. This is a crucial part of research and development for new materials.

Understanding the Limitations

While powerful, a standard laboratory incubator is not a one-size-fits-all solution. Understanding its limitations is key to proper experimental design.

Temperature is Only One Factor

A standard incubator exclusively controls temperature. It does not regulate other critical environmental factors like humidity or atmospheric gas composition.

Specialized Needs Require Specialized Equipment

The growth of more complex life forms, such as mammalian cell cultures, requires precise control of carbon dioxide (CO2) levels and high humidity to mimic internal body conditions. For these applications, a more advanced CO2 incubator is necessary.

The Risk of Cross-Contamination

Because an incubator provides ideal growing conditions, any accidental spill or airborne contamination can flourish. Without proper sterile technique, the incubator itself can become a source for contaminating other experiments.

Making the Right Choice for Your Goal

Selecting the right equipment depends entirely on the process you need to control.

- If your primary focus is basic microbiology (e.g., bacteria, yeast): A standard laboratory incubator with precise temperature control is the essential and correct tool for the job.

- If your primary focus is materials testing or shelf-life studies: You need an incubator with a verifiable, uniform temperature range that aligns with your specific industry testing standards.

- If your primary focus is growing mammalian or animal cells: You must use a specialized CO2 incubator that can control temperature, humidity, and atmospheric gas levels simultaneously.

Ultimately, mastering the use of an incubator is about understanding how to create the ideal, stable environment your specific scientific process demands.

Summary Table:

| Feature | Function | Benefit |

|---|---|---|

| Temperature Control | Maintains precise, stable heat (up to 100°C) | Ensures optimal, predictable growth rates for cultures |

| Airtight Seals | Uses magnetic door seals to isolate the chamber | Prevents contamination and temperature fluctuations |

| Circulation Fan | Distributes air evenly throughout the chamber | Eliminates hot spots, ensuring uniform conditions for all samples |

| Observation Window | Allows visual inspection without opening the door | Maintains environmental stability during monitoring |

Ready to create the ideal environment for your lab's critical processes?

Whether your work involves basic microbiology, pharmaceutical quality control, or advanced cell culture, KINTEK has the right incubator for your needs. Our range of standard and specialized equipment ensures the precise temperature control and contaminant-free environment your experiments demand.

Contact KINTEK today to discuss your specific application and find the perfect incubator to enhance the accuracy and efficiency of your work.

Visual Guide

Related Products

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

- Laboratory Hybrid Tissue Grinding Mill

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What is a laboratory mixer? A Guide to Achieving Perfect Sample Homogeneity

- Is sintered metal stronger? The Trade-Off Between Strength and Manufacturing Efficiency

- What are diamonds used for in manufacturing? Precision Cutting, Grinding & Drilling

- What is the main purpose of pyrolysis? Unlock Energy & Value from Waste

- What are the applications of DC sputtering? Achieve High-Quality Conductive Coatings for Your Industry

- What is the process of making bio-oil? Convert Biomass to Liquid Fuel via Pyrolysis

- What does FTIR read? Unlocking Molecular Fingerprints with Infrared Spectroscopy

- Will THC distillate dissolve in water? Unlocking the Science of Water-Soluble Cannabis