At its core, pyrolysis oil is a renewable liquid primarily used as a direct substitute for conventional fuel oil in stationary industrial applications like boilers and furnaces. Beyond this, its true potential lies in being upgraded into higher-value transportation fuels or serving as a feedstock for producing sustainable chemicals.

While pyrolysis oil offers a versatile pathway for converting waste into energy, its direct industrial use is limited by significant technical challenges. Overcoming these issues through upgrading is the key to unlocking its wider application as a replacement for fossil-derived products.

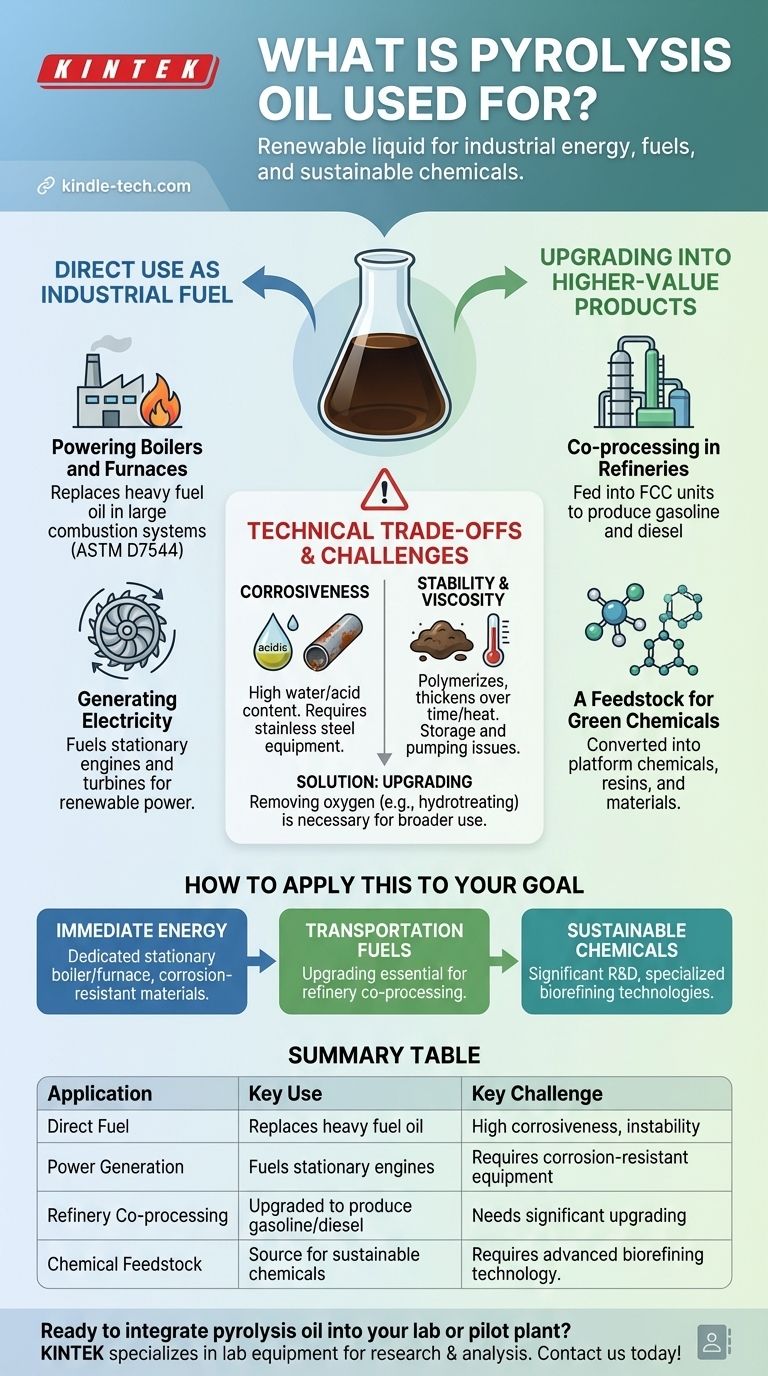

Direct Use as an Industrial Fuel

The most straightforward application for pyrolysis oil is as a heating fuel, replacing heavy fuel oil in large-scale, stationary combustion systems.

Powering Boilers and Furnaces

Pyrolysis oil can be burned in industrial boilers and furnaces found in facilities like steel mills, ceramic factories, and chemical plants. Its use in these applications is regulated by standards such as ASTM D7544, which defines the required specifications for "Pyrolysis Liquid Biofuel."

Generating Electricity

The oil can also fuel large, stationary diesel engines and turbines in power generation units. This allows for the production of renewable electricity from waste biomass or other materials like end-of-life tires.

Upgrading into Higher-Value Products

Due to its challenging properties, a more advanced use for pyrolysis oil is to process it further into more stable and valuable products that closely resemble conventional fuels and chemicals.

Co-processing in Refineries

One of the most promising pathways is to introduce upgraded pyrolysis oil into existing petroleum refineries. By feeding it into units like a fluid catalytic cracker (FCC), it can be co-processed alongside crude oil fractions to produce gasoline and diesel.

A Feedstock for Green Chemicals

Pyrolysis oil is a complex mixture of oxygenated organic compounds. Through advanced biorefining processes, these compounds can be extracted or converted into platform chemicals, resins, and other materials that are currently derived from fossil fuels.

Understanding the Technical Trade-offs

The widespread adoption of pyrolysis oil is not a simple plug-and-play substitution. Its unique chemical properties create significant technical hurdles that must be addressed.

The Problem of Corrosiveness

Pyrolysis oil typically contains a high amount of water and organic acids, making it highly corrosive to common metals like carbon steel. This requires specialized storage tanks, pumps, and fuel lines made from stainless steel, increasing infrastructure costs.

Issues with Stability and Viscosity

The oil is chemically unstable. Over time, or when heated, its reactive components can polymerize, causing the oil to thicken, form sludge, and increase in viscosity. This creates problems with long-term storage, pumping, and proper atomization in burners.

The Inherent Need for Upgrading

These challenges of corrosiveness and instability are why direct use is often limited to specific, adapted equipment. Upgrading the oil—typically by removing oxygen through processes like hydrotreating—is often a necessary step to create a more stable, less corrosive, and energy-dense intermediate product suitable for refining or broader use.

How to Apply This to Your Goal

Your strategy for using pyrolysis oil depends entirely on your end goal and your capacity to handle its technical challenges.

- If your primary focus is immediate energy generation: Your best path is using the oil in a dedicated stationary boiler or furnace, ensuring your equipment is built with corrosion-resistant materials.

- If your primary focus is producing transportation fuels: Direct use is not viable; the strategy must involve upgrading the oil so it can be co-processed in a conventional refinery.

- If your primary focus is creating sustainable chemicals: This requires significant R&D and investment in specialized biorefining technologies to isolate and convert the valuable compounds within the oil.

Understanding these distinct pathways and their associated technical demands is the key to effectively harnessing the potential of pyrolysis oil.

Summary Table:

| Application | Key Use | Key Challenge |

|---|---|---|

| Direct Fuel | Replaces heavy fuel oil in boilers & furnaces | High corrosiveness, instability |

| Power Generation | Fuels stationary engines for electricity | Requires corrosion-resistant equipment |

| Refinery Co-processing | Upgraded to produce gasoline/diesel | Needs significant upgrading (e.g., hydrotreating) |

| Chemical Feedstock | Source for sustainable chemicals & resins | Requires advanced biorefining technology |

Ready to integrate pyrolysis oil into your lab or pilot plant? KINTEK specializes in lab equipment and consumables for pyrolysis research and analysis. Whether you're testing oil stability, upgrading processes, or developing new chemical pathways, our reliable tools help you overcome technical challenges efficiently. Contact us today to explore how our solutions can accelerate your renewable energy projects!

Visual Guide

Related Products

- FS Electrochemical Hydrogen Fuel Cells for Diverse Applications

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Customizable CO2 Reduction Flow Cell for NRR ORR and CO2RR Research

- Customizable PEM Electrolysis Cells for Diverse Research Applications

People Also Ask

- What are the factors that affect sample size? Optimize Your Study's Power and Precision

- How much more efficient are electric arc furnaces? Achieve 90% Energy Savings in Steel Production

- What are some common drying methods used in laboratories and their drawbacks? Choose the Right Method to Protect Your Samples

- What are the latest technologies in additive manufacturing? From Prototyping to Mass Production

- What are diamonds used for in manufacturing? Precision Cutting, Grinding & Drilling

- Why is argon used as a plasma gas? The Ideal Balance for Efficient Sputtering

- Why is deposition technology an amazing scientific advancement? Unlock Atomic-Level Material Engineering

- What are the advantages of pyrolysis in converting biomass to energy? Unlock Multiple Value Streams from Waste