Sintered iron is a solid metallic component created from iron powder through a manufacturing process called sintering. Instead of melting the metal, this process uses heat and pressure to compact and fuse the powder particles together, forming a strong, finished part that is often complex in shape. This method is a cornerstone of powder metallurgy.

Sintering is a manufacturing process that transforms metal powders, including iron, into solid components without reaching their melting point. This approach is uniquely suited for producing intricate, net-shape parts at a lower cost and with less material waste than traditional casting or machining.

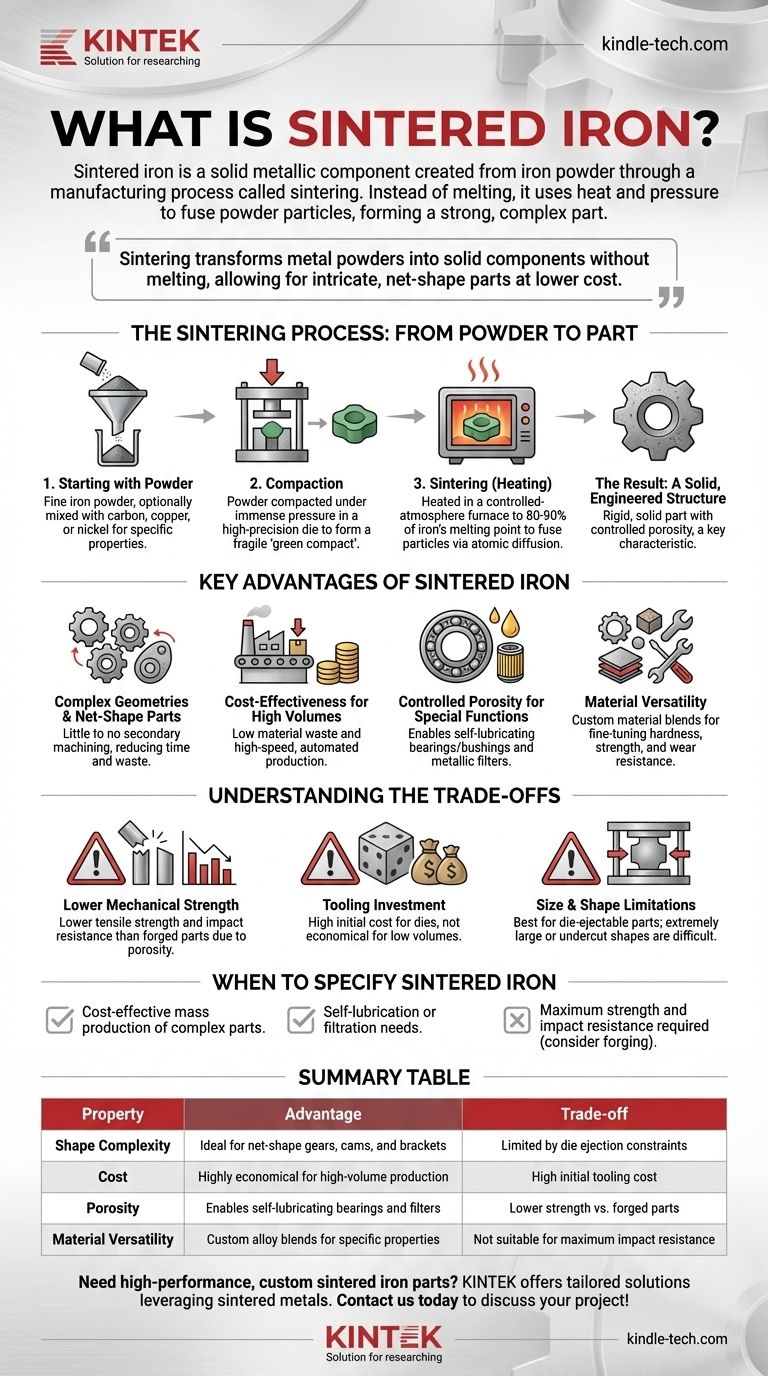

The Sintering Process: From Powder to Part

Understanding sintered iron requires understanding the process that creates it. It's a multi-step technique that turns a loose powder into a precise, solid component.

Step 1: Starting with Powder

The raw material is a fine metallic powder, which in this case is primarily iron. Other elements like carbon, copper, or nickel can be blended into the iron powder to create specific alloys with desired properties.

Step 2: Compaction

The powder mix is poured into a high-precision die cavity and compacted under immense pressure. This action forces the powder particles into close contact, forming a fragile, pre-shaped component known as a "green compact."

Step 3: Sintering (Heating)

The green compact is then moved into a controlled-atmosphere furnace and heated to a high temperature, typically around 80-90% of iron's melting point. This heat provides the energy for the individual powder particles to bond and fuse together through atomic diffusion, creating a solid, metallic structure.

The Result: A Solid, Engineered Structure

The final product is a rigid, solid part with the desired shape. A key characteristic of sintered components is their inherent, controlled porosity. This network of tiny voids is a natural result of the process and can be engineered as a beneficial feature.

Key Advantages of Sintered Iron

Engineers and designers specify sintered iron to leverage its unique combination of properties and manufacturing benefits.

Complex Geometries and Net-Shape Parts

Sintering excels at producing complex shapes, such as gears, cams, and structural brackets, directly from the die. These are called net-shape or near-net-shape parts because they require little to no secondary machining, drastically reducing production time and material waste.

Cost-Effectiveness for High Volumes

While the initial tooling (the die) can be expensive, the low material waste and high-speed, automated nature of the process make sintering extremely cost-effective for medium-to-high volume production runs.

Controlled Porosity for Special Functions

The porosity of sintered iron can be precisely controlled. This allows parts to be impregnated with lubricants, leading to the creation of self-lubricating bearings and bushings. This same porosity can also be used to produce metallic filters for various fluid and gas applications.

Material Versatility

The powder-based approach allows for the creation of custom material blends that would be difficult or impossible to produce through melting and casting. This allows for fine-tuning properties like hardness, strength, and wear resistance.

Understanding the Trade-offs

No process is perfect. Sintered iron has specific limitations that make it unsuitable for certain applications.

Lower Mechanical Strength

Due to its inherent porosity, a sintered iron part will generally have lower tensile strength and impact resistance compared to a fully dense component made by forging or machining from solid bar stock.

Tooling Investment

The high cost of the compaction dies means that sintering is not economical for prototypes or very low-volume production runs. The cost must be justified by the quantity of parts being produced.

Size and Shape Limitations

While excellent for complexity, the process is best suited for parts that can be ejected from a die. Extremely large components or shapes with certain undercuts can be difficult or impossible to produce with traditional press-and-sinter methods.

When to Specify Sintered Iron

Use this as a guide to determine if sintered iron is the right choice for your project's goals.

- If your primary focus is cost-effective mass production: Sintered iron is ideal for creating thousands of identical, complex parts with minimal material waste or machining.

- If your primary focus is self-lubrication or filtration: The controlled porosity of sintered iron makes it a superior choice for applications like bearings, bushings, and filters.

- If your primary focus is maximum strength and impact resistance: You should consider alternative methods like forging or machining from bar stock, as sintered parts are typically less robust.

Ultimately, choosing sintered iron is a strategic decision to leverage its unique manufacturing advantages for applications where net-shape complexity and specialized properties outweigh the need for maximum mechanical strength.

Summary Table:

| Property | Advantage | Trade-off |

|---|---|---|

| Shape Complexity | Ideal for net-shape gears, cams, and brackets | Limited by die ejection constraints |

| Cost | Highly economical for high-volume production | High initial tooling cost |

| Porosity | Enables self-lubricating bearings and filters | Lower strength vs. forged parts |

| Material Versatility | Custom alloy blends for specific properties | Not suitable for maximum impact resistance |

Need high-performance, custom sintered iron parts for your laboratory or production line?

KINTEK specializes in precision lab equipment and consumables, offering tailored solutions that leverage the unique benefits of sintered metals. Whether you require complex net-shape components, self-lubricating bearings, or specialized filters, our expertise ensures you get durable, cost-effective parts designed for your specific application.

Contact us today to discuss how sintered iron can optimize your project!

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for Hydrothermal Synthesis Reactor Polytetrafluoroethylene Carbon Paper and Carbon Cloth Nano-growth

- Custom PTFE Teflon Parts Manufacturer for Non-Standard Insulator Customization

- Custom PTFE Teflon Parts Manufacturer for PTFE Ball Valve Seat

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- What is sputter coating in SEM? Essential Guide to Preventing Charging and Enhancing Image Quality

- Is heat treatment used to alter properties of metal alloy? Master Microstructure for Superior Performance

- What is sputter coated glass? Discover High-Performance Solar Control Technology

- Can biomass replace coal? The Complex Reality of a Green Energy Alternative

- What are the 5 heat treatment processes? Master Annealing, Hardening, Tempering & More

- Is XRF analyzer radiation safe? Learn How Modern XRF Technology Ensures Operator Safety

- What are the advantages and applications of sintering process? Achieve Strong, Complex Parts Efficiently

- What is the material of filter press? Why Reinforced Polypropylene is the Industry Standard