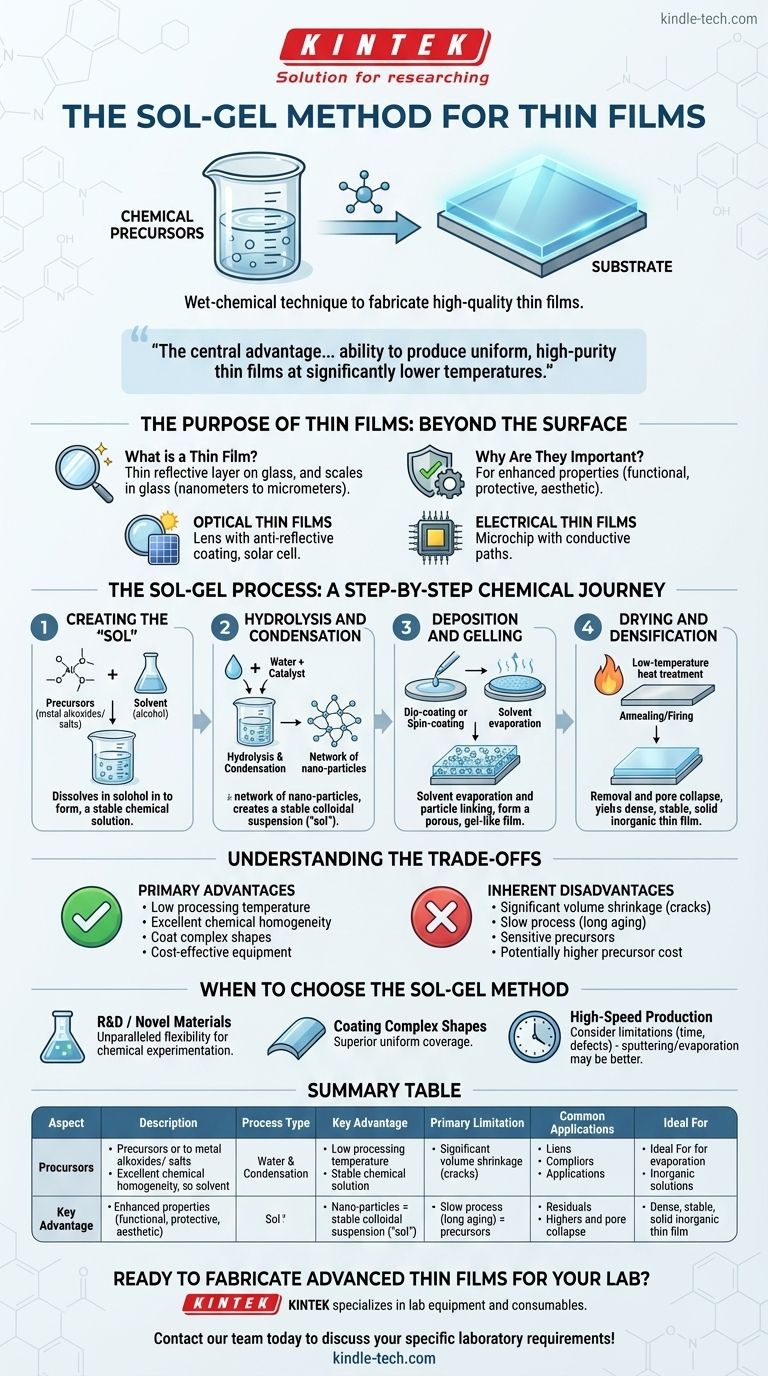

At its core, the sol-gel method is a versatile "wet-chemical" technique used to fabricate high-quality thin films from chemical precursors. Unlike physical methods that deposit material atom-by-atom in a vacuum, sol-gel builds films by transitioning a chemical solution (a "sol") into a solid gel-like network directly onto a substrate's surface. This process allows for excellent control over the material's composition and purity.

The central advantage of the sol-gel method is its ability to produce uniform, high-purity thin films at significantly lower temperatures than traditional melting or sintering techniques. It offers a powerful, low-cost chemical route to create advanced materials with precisely engineered properties.

The Purpose of Thin Films: Beyond the Surface

To understand the value of the sol-gel method, we must first appreciate the role of thin films. These are not simply coatings; they are engineered layers that fundamentally alter the properties of a base material.

What is a Thin Film?

A thin film is a layer of material ranging from a few nanometers to several micrometers in thickness. At this scale, the material's properties can be dramatically different from its bulk form due to the high surface-area-to-volume ratio.

A common household mirror is a perfect example. It's a thin, reflective metal coating applied to the back of a glass sheet, creating a new optical interface where one did not exist before.

Why Are They So Important?

Thin films are used to impart new characteristics onto a substrate. These enhancements can be functional, protective, or aesthetic.

Common benefits include improved corrosion and wear resistance, increased durability, and unique optical or electrical properties. This makes them critical components in countless industries.

The Two Primary Categories

Thin films generally fall into two categories based on their primary function:

- Optical Thin Films: Used for anti-reflective coatings on lenses, reflective coatings on mirrors, and in the fabrication of solar cells and monitors.

- Electrical Thin Films: Used to create insulators, conductors, and semiconductors, forming the basis for integrated circuits and other electronic devices.

The Sol-Gel Process: A Step-by-Step Chemical Journey

The sol-gel method is a precise chemical pathway that transforms liquid precursors into a solid inorganic film. The process typically involves four key stages.

Step 1: Creating the "Sol"

The process begins with chemical precursors, often metal alkoxides or metal salts, which are dissolved in a solvent (typically an alcohol). This initial mixture is a stable chemical solution.

Step 2: Hydrolysis and Condensation

Water and a catalyst (acid or base) are added to the solution. This initiates two critical chemical reactions:

- Hydrolysis: The precursor molecules react with water.

- Condensation: The hydrolyzed molecules link together, forming a network of nano-sized particles suspended in the liquid. This stable colloidal suspension is the "sol."

Step 3: Deposition and Gelling

The sol is applied to a substrate using techniques like dip-coating or spin-coating. As the solvent evaporates, the suspended particles are drawn closer together and continue to link up.

This process forms a continuous solid network that immobilizes the remaining liquid, creating a porous, gel-like film.

Step 4: Drying and Densification

The final stage is a low-temperature heat treatment, often called annealing or firing. This crucial step removes residual organic compounds and water from the gel's pores.

The porous gel structure collapses, resulting in a dense, stable, and solid inorganic thin film with the desired final properties.

Understanding the Trade-offs

No single method is perfect for every application. The sol-gel technique has clear advantages but also comes with limitations that must be considered.

The Primary Advantages

The main strengths of the sol-gel method are its low processing temperature, which allows for coating heat-sensitive materials, and its excellent chemical homogeneity, ensuring a uniform composition throughout the film.

Furthermore, it offers the ability to coat complex shapes and generally requires less expensive equipment than high-vacuum physical deposition systems.

The Inherent Disadvantages

The primary drawback is the significant volume shrinkage that occurs as the gel dries and densifies. This can create internal stress, leading to cracks in thicker films.

Additionally, the process can be slow due to long aging or drying times. The chemical precursors can also be sensitive to environmental moisture and may be more expensive than the raw materials used in other methods.

When to Choose the Sol-Gel Method

Selecting the right fabrication technique depends entirely on your project's goals, budget, and material requirements.

- If your primary focus is R&D or creating novel material compositions: Sol-gel offers unparalleled flexibility for experimenting with chemical stoichiometry and doping at a relatively low cost.

- If your primary focus is coating large or complex-shaped substrates: The "wet" application method is often superior to line-of-sight physical deposition techniques for achieving uniform coverage.

- If your primary focus is high-speed industrial production: Be mindful of the long processing times and potential for shrinkage-induced defects, which may make methods like sputtering or evaporation more suitable.

By understanding this chemical pathway, you can fabricate advanced thin films with a remarkable degree of precision and control.

Summary Table:

| Aspect | Description |

|---|---|

| Process Type | Wet-chemical (chemical solution deposition) |

| Key Advantage | Low-temperature processing & excellent chemical homogeneity |

| Primary Limitation | Significant shrinkage during drying, risk of cracking |

| Common Applications | Optical coatings, protective layers, electronic components |

| Ideal For | R&D, coating complex shapes, cost-effective prototyping |

Ready to Fabricate Advanced Thin Films for Your Lab?

The sol-gel method is a powerful tool for creating high-purity coatings. At KINTEK, we specialize in providing the high-quality lab equipment and consumables you need to perfect your thin film processes, from precise coating systems to reliable thermal treatment furnaces.

Let our experts help you select the right tools to achieve superior material properties and accelerate your research and development. Contact our team today to discuss your specific laboratory requirements!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What is the synthesis and mechanism involved in the preparation of carbon nanotubes using CVD process? Master Controlled Growth for Your Application

- What does the deposition rate depend on? Key Factors for Thin-Film Process Control

- What are the applications of thin-film in renewable energy? Beyond Solar Panels to Energy Storage & Hydrogen

- What are the limitations of sputtering? High Costs, Slow Speeds, and Material Damage

- What is the easiest way to make graphene? Match the Method to Your Goal

- What are the advantages of chemical bath deposition? A Low-Cost, Scalable Thin Film Solution

- What are the materials for thin film technologies? Choose the Right Material for Your Application

- What is the thermal conductivity of graphene with temperature? Unlock Its Dynamic Heat Management Potential