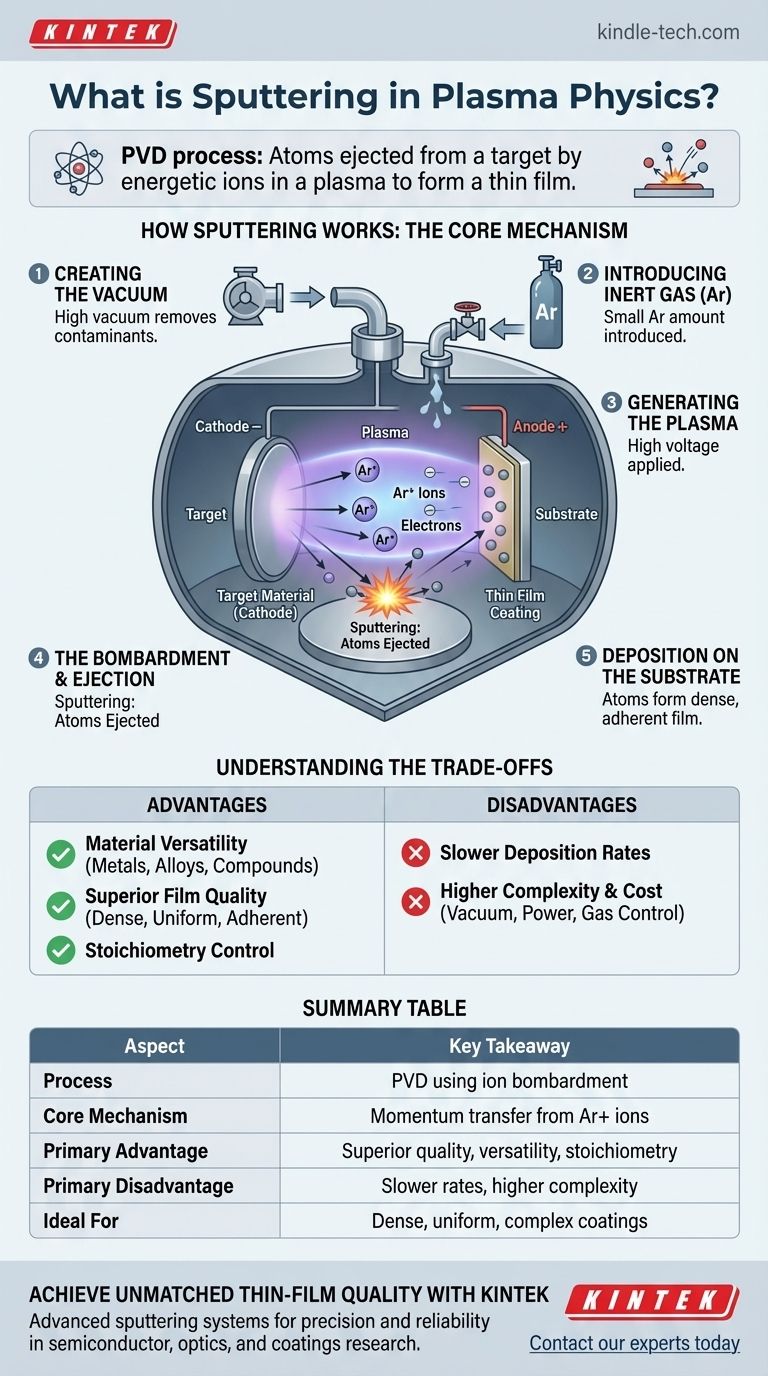

In the field of plasma physics, sputtering is a physical vapor deposition (PVD) process where atoms are ejected from a solid target material by bombarding it with energetic ions. These ions are generated within a low-pressure gas environment known as a plasma. The ejected atoms then travel through the vacuum chamber and deposit onto a substrate, forming a thin, highly uniform film.

Sputtering is best understood as a form of atomic-scale sandblasting. It uses high-energy ions from a plasma to physically knock atoms loose from a source material, which then re-deposit as a high-quality coating onto a separate surface.

How Sputtering Works: The Core Mechanism

Sputtering is not a chemical reaction but a physical process driven by momentum transfer. The entire operation takes place inside a high-vacuum chamber to ensure the purity and controlled travel of the ejected atoms.

Step 1: Creating the Vacuum

The process begins by pumping a chamber down to a high vacuum. This removes ambient gases like oxygen and nitrogen, which would otherwise contaminate the target and the resulting film.

A clean environment is critical for ensuring the sputtered atoms can travel from the target to the substrate without colliding with unwanted particles.

Step 2: Introducing an Inert Gas

A small, precisely controlled amount of an inert process gas, most commonly Argon (Ar), is introduced into the chamber. This gas is too sparse to significantly impede the sputtered atoms, but it provides the raw material needed to create the plasma.

Argon is chosen because it is chemically inert and has a sufficient atomic mass to effectively dislodge atoms from the target without reacting with them.

Step 3: Generating the Plasma

A high voltage is applied between two electrodes inside the chamber. The target material (the source of the coating) is made into the cathode (negative electrode).

This strong electric field strips electrons from some of the Argon atoms, creating a mixture of free electrons and positively charged Argon ions (Ar+). This energized, ionized gas is the plasma, which often appears as a characteristic glow.

Step 4: The Bombardment and Ejection

The positively charged Argon ions are forcefully accelerated by the electric field and slam into the negatively charged target.

Upon impact, each ion transfers its kinetic energy to the atoms in the target material. If the energy transfer is sufficient, it will knock one or more target atoms completely out of the solid surface, a process called sputtering.

Step 5: Deposition on the Substrate

The ejected atoms from the target travel through the vacuum chamber and land on a substrate (the object to be coated), which is strategically placed nearby.

As these atoms accumulate on the substrate's surface, they build up layer by layer, forming a thin, dense, and highly adherent film.

Understanding the Trade-offs of Sputtering

Like any precision engineering process, sputtering has distinct advantages and disadvantages that make it suitable for specific applications.

Advantage: Material Versatility

Sputtering can be used to deposit films from an incredibly wide range of materials, including pure metals, alloys, and even insulating compounds (using a technique called RF sputtering). Because it's a physical process, it can deposit materials with very high melting points that are impossible to handle with thermal evaporation.

Crucially, when sputtering from an alloy target, the resulting film typically retains the same chemical composition, or stoichiometry, as the source material.

Advantage: Superior Film Quality

The sputtered atoms are ejected with significantly higher kinetic energy than those in thermal evaporation processes. This energy helps them form a denser, more uniform, and more strongly adhered film on the substrate.

Disadvantage: Slower Deposition Rates

Sputtering is generally a much slower process than other PVD methods like thermal evaporation. The rate of atom ejection is fundamentally less efficient, making it less suitable for applications requiring very thick coatings or high-speed production.

Disadvantage: Complexity and Cost

Sputtering systems require high-vacuum equipment, sophisticated power supplies (DC or RF), and precise gas flow control. This makes the initial equipment investment and operational complexity higher than simpler coating methods.

Making the Right Choice for Your Application

Choosing a deposition method depends entirely on the desired properties of the final film.

- If your primary focus is coating with complex alloys or compounds: Sputtering is the superior choice due to its ability to preserve the material's original stoichiometry.

- If your primary focus is achieving the highest film adhesion and density: The high energy of sputtered particles makes it the ideal method for creating durable, high-quality films.

- If your primary focus is rapid, low-cost deposition of a simple metal: A technique like thermal evaporation may be a more efficient and economical alternative to consider.

By understanding the principles of sputtering, you gain precise control over the creation of materials at the atomic level.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Process | Physical vapor deposition (PVD) using ion bombardment. |

| Core Mechanism | Momentum transfer from energetic ions (e.g., Ar+) to a target material. |

| Primary Advantage | Superior film quality, high material versatility, and excellent stoichiometry control. |

| Primary Disadvantage | Slower deposition rates and higher system complexity/cost. |

| Ideal For | Applications requiring dense, uniform, and highly adherent coatings from complex materials. |

Achieve Unmatched Thin-Film Quality with KINTEK

Understanding the nuances of sputtering is the first step. Implementing it successfully in your lab is the next. KINTEK specializes in high-performance lab equipment, including advanced sputtering systems designed for precision and reliability.

Whether you are developing new semiconductor components, advanced optics, or wear-resistant coatings, our expertise ensures you get the dense, uniform films your research demands.

Let's discuss how a KINTEK sputtering system can enhance your capabilities. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Evaporation Boat for Organic Matter

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the components of PECVD? A Guide to Low-Temperature Thin Film Deposition Systems

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells