In short, reactive sputtering is used to create high-performance compound thin films for industries ranging from semiconductors to aerospace. Its primary applications include depositing dielectrics for microelectronics, creating thin-film resistors with precise electrical properties, and forming extremely hard, wear-resistant coatings on tools and components.

The crucial insight is that reactive sputtering is not just a coating technique; it is a film synthesis technique. It creates an entirely new material—such as an oxide or nitride—directly on a substrate by combining atoms from a pure target with a reactive gas, offering precise control over the final film's composition and properties.

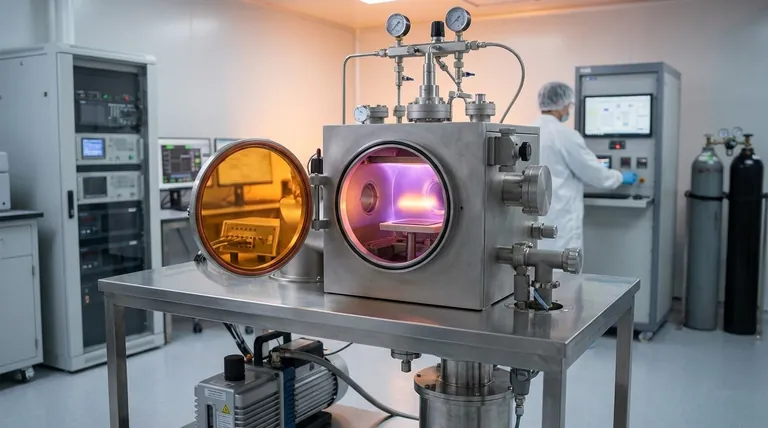

How Reactive Sputtering Works

The Core Principle: A Target and a Reactive Gas

Reactive sputtering is a high-vacuum process that begins like standard sputtering: ions are used to bombard a pure elemental target (e.g., titanium, silicon, tantalum), knocking atoms loose.

The key difference is the introduction of a reactive gas, such as oxygen or nitrogen, into the vacuum chamber along with the standard inert gas (like argon).

Creating New Compounds on Demand

As the sputtered atoms from the target travel toward the substrate, they chemically react with the gas molecules. This reaction forms a new compound.

For example, sputtering a titanium target in a nitrogen atmosphere doesn't deposit a titanium film. Instead, it creates an exceptionally hard titanium nitride (TiN) film on the substrate. Sputtering a silicon target in an oxygen atmosphere produces silicon dioxide (SiO₂).

Precision Control over Film Properties

This process allows for the creation of compound films with highly controlled stoichiometry—the precise ratio of elements.

By carefully managing the gas pressure and sputtering rate, engineers can fine-tune the film's electrical, optical, and mechanical properties to meet very specific requirements.

Key Industrial Applications in Detail

Semiconductors and Electronics

Reactive sputtering is fundamental to modern electronics for creating insulating layers and components with specific electrical resistance.

It is used to deposit high-purity dielectrics like aluminum oxide (Al₂O₃) or silicon dioxide (SiO₂), which are critical for manufacturing capacitors and transistors. It is also the preferred method for producing thin-film resistors, such as those made from tantalum nitride (TaN).

Protective and Hard Coatings

The technique excels at producing hard, chemically stable coatings that protect surfaces from wear, corrosion, and high temperatures.

Titanium nitride (TiN), known for its gold-like appearance and extreme hardness, is a common coating applied to cutting tools, drill bits, and industrial molds to dramatically extend their operational life.

Optical Devices

In the field of optics, reactive sputtering is used to deposit thin films with specific refractive indices for applications like anti-reflection coatings on lenses.

Materials like silicon nitride (Si₃N₄) and titanium dioxide (TiO₂) are deposited with precise thickness to control how light is transmitted or reflected, enhancing the performance of optical systems.

Understanding the Trade-offs

Process Control is Critical

The main challenge of reactive sputtering is maintaining the delicate balance between the sputtering rate and the flow of reactive gas.

Too little gas results in a film contaminated with the pure target material, while too much gas can lead to a phenomenon known as "target poisoning," where the target surface itself reacts, drastically slowing the process and altering film properties.

Potentially Slower Deposition Rates

Compared to non-reactive sputtering of a pure metal, the deposition rate can sometimes be lower due to the chemical reactions involved and the need to avoid target poisoning.

This trade-off of speed for compositional control is a key consideration in high-volume manufacturing environments.

When to Choose Reactive Sputtering

- If your primary focus is creating high-purity compound films: Reactive sputtering is the ideal choice for depositing oxides, nitrides, and carbides with precise elemental ratios.

- If your primary focus is achieving specific electrical properties: This technique provides the control needed to produce high-performance dielectrics, insulators, and resistors for electronic devices.

- If your primary focus is producing durable, wear-resistant surfaces: It is a leading method for applying hard coatings that significantly enhance the longevity and performance of tools and mechanical parts.

Ultimately, reactive sputtering is the go-to technique whenever the goal is to synthesize a high-quality compound film directly onto a surface with exceptional control.

Summary Table:

| Application Area | Key Materials | Primary Benefits |

|---|---|---|

| Semiconductors & Electronics | SiO₂, Al₂O₃, TaN | High-purity dielectrics, precise electrical properties |

| Protective & Hard Coatings | TiN, TiAlN | Extreme hardness, wear and corrosion resistance |

| Optical Devices | Si₃N₄, TiO₂ | Controlled refractive index, anti-reflection coatings |

Need to deposit high-performance compound films with precise control? KINTEK specializes in advanced lab equipment, including sputtering systems, to help you synthesize oxides, nitrides, and other custom coatings for your R&D or production needs. Our experts can guide you to the right solution for your specific application in semiconductors, protective coatings, or optics. Contact us today to discuss your project requirements!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What materials are used in electron beam evaporation? Master High-Purity Thin Film Deposition

- What is e-beam used for? A High-Speed, Non-Thermal Solution for Sterilization & Material Enhancement

- What is a reactive sputtering reaction? Synthesize Advanced Thin Films with Precision

- What is the use of torrefaction? Upgrade Biomass into High-Energy 'Bio-Coal'

- What are the effects of high temperature sintering? Unlock Dense, Strong Components or Risk Defects

- How does a mechanical stirring device contribute to the uniformity of doped oxide coatings? Boost PEO Catalyst Quality

- What are the disadvantages of a screw compressor? Key Trade-offs to Consider Before Buying

- What are the disadvantages of using metal? Understanding Corrosion, Weight, and Cost Challenges