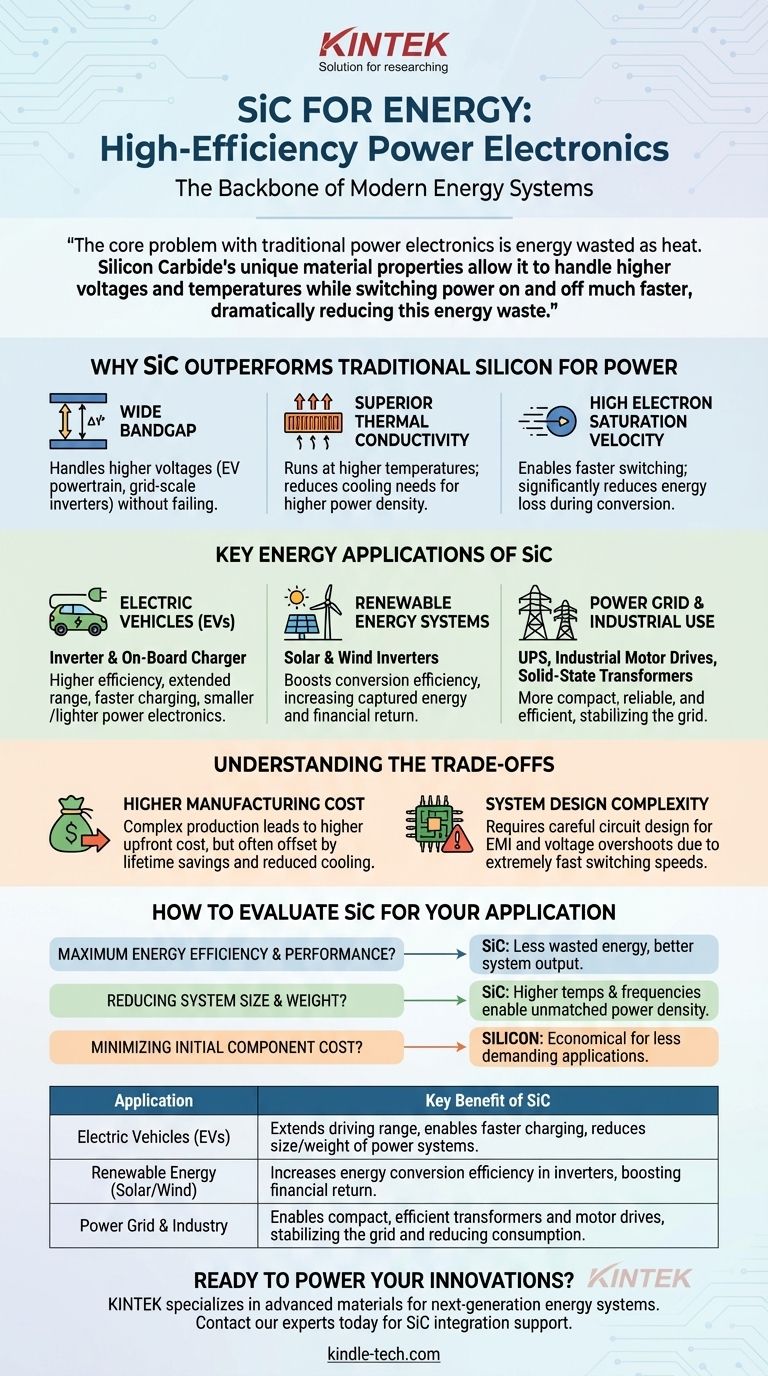

In the energy sector, Silicon Carbide (SiC) is primarily used to build highly efficient power electronics. These advanced semiconductor devices are responsible for converting and controlling electricity with significantly less energy loss than traditional silicon components. They are becoming the backbone of modern energy systems, from electric vehicles and solar power inverters to the stability of the entire power grid.

The core problem with traditional power electronics is energy wasted as heat. Silicon Carbide's unique material properties allow it to handle higher voltages and temperatures while switching power on and off much faster, dramatically reducing this energy waste and enabling smaller, more powerful, and more efficient energy systems.

Why SiC Outperforms Traditional Silicon for Power

The advantages of SiC are not incremental; they represent a fundamental shift in what is possible for power electronics. This stems from its intrinsic physical properties, which are far more suitable for high-power applications than those of conventional silicon.

The Significance of a Wide Bandgap

A material's bandgap determines how much energy is needed to allow electrons to flow and conduct electricity. SiC has a bandgap roughly three times wider than silicon.

This wide bandgap means SiC devices can block much higher voltages before breaking down. This allows for the creation of components that can handle the high-power demands of an EV powertrain or a grid-scale inverter without failing.

Superior Thermal Conductivity

SiC is exceptionally good at conducting heat away from its core. This high thermal conductivity is a critical advantage.

Because SiC dissipates heat so effectively, devices can run at higher temperatures without damage. This reduces the need for large, heavy, and expensive cooling systems like fans and heatsinks, leading to a dramatic increase in power density (more power in a smaller space).

High Electron Saturation Velocity

This property allows electrons to move through SiC at very high speeds. In practical terms, this enables SiC devices to switch on and off much faster than silicon-based devices.

Faster switching directly reduces the amount of energy lost during the power conversion process (known as switching losses). This is the primary driver of SiC's superior energy efficiency.

Key Energy Applications of SiC

The theoretical benefits of SiC translate into tangible performance gains across several critical energy sectors.

Electric Vehicles (EVs)

SiC is a game-changer for EVs. It is used in the main inverter, which converts DC power from the battery to AC power for the motor, and in the on-board charger.

The result is higher efficiency, which extends the vehicle's driving range on a single charge. It also enables faster charging times and reduces the weight and size of the power electronics, further improving vehicle performance.

Renewable Energy Systems

In solar energy, inverters are required to convert the DC electricity generated by panels into grid-compatible AC electricity.

Using SiC in solar inverters boosts conversion efficiency, meaning more of the sun's energy is captured and delivered to the grid or for local use. This increases the financial return and overall energy output of a solar installation. The same benefits apply to power converters in wind turbines.

Power Grid and Industrial Use

SiC is being deployed in data centers for uninterruptible power supplies (UPS) and in factories for high-efficiency industrial motor drives, reducing electricity consumption.

On the grid itself, SiC enables the development of solid-state transformers, which are more compact, reliable, and efficient than traditional transformers, helping to modernize and stabilize the electrical grid.

Understanding the Trade-offs

While SiC offers clear advantages, it is essential to recognize its current limitations to make an informed decision.

Higher Manufacturing Cost

Producing high-purity, defect-free SiC wafers is a more complex and energy-intensive process than producing silicon wafers.

This results in a higher upfront cost for SiC components. However, this cost is often offset over the system's lifetime through significant energy savings and reduced cooling requirements. As manufacturing scales, prices are steadily declining.

System Design Complexity

You cannot simply replace a silicon component with a SiC one. The extremely fast switching speeds of SiC devices require more careful circuit design to manage electromagnetic interference (EMI) and voltage overshoots.

Engineers must possess specific expertise to properly integrate SiC components and unlock their full performance potential without introducing new issues into the system.

How to Evaluate SiC for Your Application

Choosing between SiC and traditional silicon depends entirely on your project's primary objective.

- If your primary focus is maximum energy efficiency and performance: SiC is the superior choice, as its low switching losses directly translate to less wasted energy and better system output.

- If your primary focus is reducing system size and weight: SiC's ability to operate at higher temperatures and frequencies allows for smaller passive components and cooling systems, enabling unmatched power density.

- If your primary focus is minimizing initial component cost: Traditional silicon remains a viable, economical option for lower-power or less demanding applications where peak efficiency is not the most critical factor.

By understanding these principles, you can confidently determine where SiC offers a decisive advantage for your energy goals.

Summary Table:

| Application | Key Benefit of SiC |

|---|---|

| Electric Vehicles (EVs) | Extends driving range, enables faster charging, reduces size/weight of power systems. |

| Renewable Energy (Solar/Wind) | Increases energy conversion efficiency in inverters, boosting financial return. |

| Power Grid & Industry | Enables compact, efficient transformers and motor drives, stabilizing the grid and reducing consumption. |

Ready to Power Your Innovations with High-Efficiency Solutions?

KINTEK specializes in providing advanced materials and components for next-generation energy systems. If you're developing power electronics for electric vehicles, renewable energy, or grid technology, our expertise can help you integrate high-performance materials like Silicon Carbide (SiC) to achieve superior efficiency, power density, and reliability.

Contact our experts today to discuss how we can support your laboratory and production needs with precision equipment and consumables tailored to the energy sector.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance