At its core, an electrode holder is a simple device with three fundamental parts. It consists of a clip head to secure the material being tested, an insulating rod that serves as a handle, and a binding post to connect the entire assembly to an external electrochemical workstation. This structure ensures a stable mechanical grip and a reliable electrical connection for your sample.

The electrode holder is more than a simple clamp; it is a critical interface designed to introduce a specific material (the working electrode) into an electrochemical cell while isolating it electrically and chemically from everything but the intended reaction.

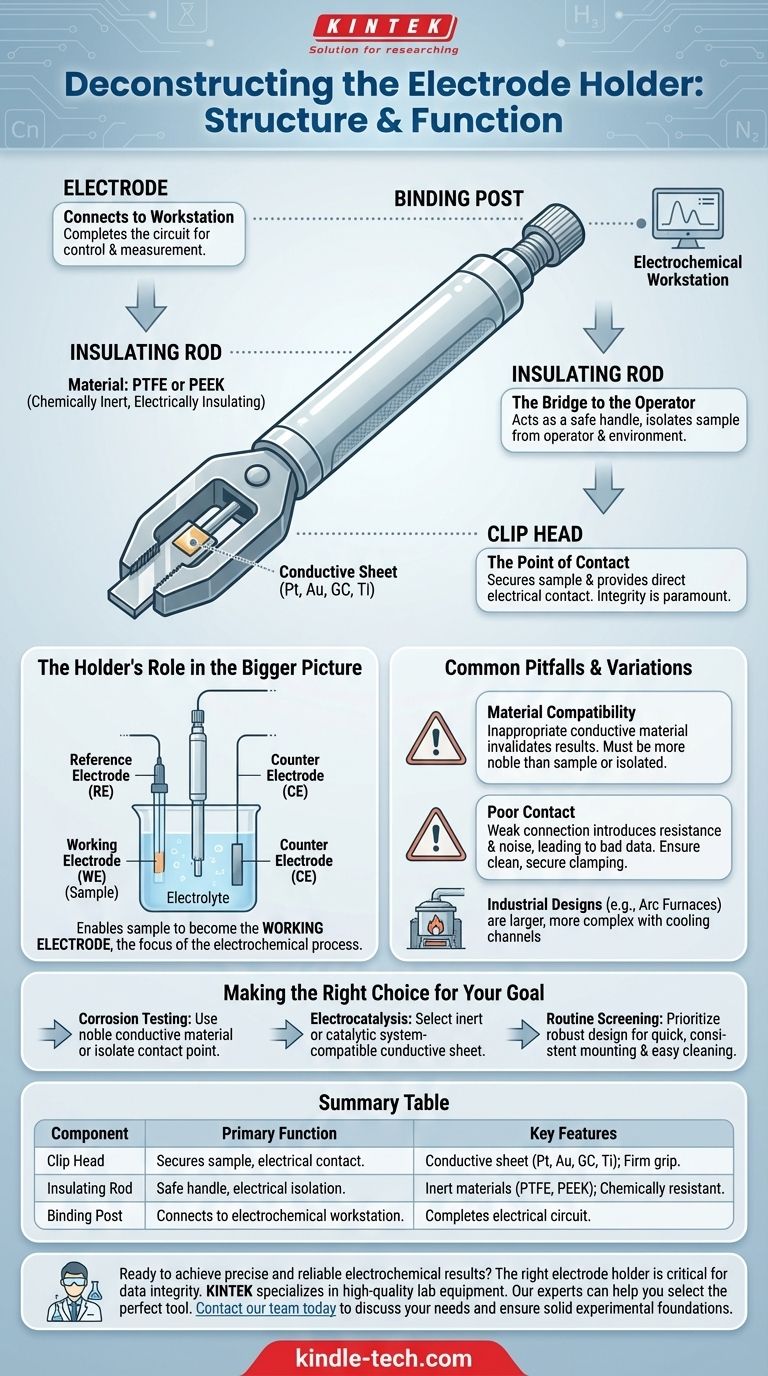

Deconstructing the Electrode Holder: Form Follows Function

Each component of an electrode holder is purpose-built to fulfill a specific role. Understanding these roles is key to performing accurate and repeatable experiments.

The Clip Head: The Point of Contact

The clip head is the business end of the holder. Its primary mechanical job is to firmly clamp the sample, which could be a piece of metal, a coated substrate, or a thin film.

Inside the clip, a conductive sheet makes direct electrical contact with the sample. The integrity of this connection is paramount for a successful measurement.

This conductive element is typically made from materials like platinum, gold, glassy carbon, or titanium. The choice is not arbitrary; it depends on the chemical environment and the reactions being studied to ensure the sheet itself does not corrode or interfere with the results.

The Insulating Rod: The Bridge to the Operator

The rod serves as the handle, allowing the operator to position the sample within the electrochemical cell without touching any active parts.

It is almost always constructed from a chemically inert and electrically insulating material, such as PTFE (Teflon) or PEEK. This material science is critical for two reasons: it protects the operator from any electrical potential and prevents the holder from becoming an unwanted participant in the electrochemical reaction.

The Binding Post: The Connection to the System

Located at the top of the rod, the binding post is the connection point. This is where you attach the cable leading to your electrochemical workstation or potentiostat.

This post completes the circuit, allowing the workstation to control the voltage or current applied to your sample and measure its response.

The Holder's Role in the Bigger Picture

The electrode holder does not function in a vacuum. It is the tool that enables your sample to become the central focus of the experiment.

Why It's the "Working Electrode"

In a typical three-electrode setup, the sample secured by the holder becomes the Working Electrode (WE).

The WE is the electrode where the electrochemical process of interest—be it corrosion, deposition, or catalysis—actually occurs. The holder's job is to ensure that the only thing the system "sees" is the sample you intend to study.

Common Pitfalls and Variations

While the design seems straightforward, improper use or misunderstanding its nuances can lead to failed experiments.

Material Compatibility is Non-Negotiable

Using a holder with an inappropriate conductive material can invalidate your results. If the conductive sheet is less chemically resistant than your sample, it may corrode preferentially and give you misleading data.

Poor Contact Leads to Bad Data

A common source of error is a weak or inconsistent connection between the sample and the internal conductive sheet. This introduces unwanted resistance, noise, and instability into your measurements, making the results unreliable. Always ensure your sample is clean and clamped securely.

Different Scales, Different Designs

The holder described here is typical for laboratory research. For industrial applications like electric arc furnaces, electrode holders are far more complex, incorporating features like active water-cooling channels and heavy-duty hanging mechanisms to manage immense electrical currents and heat.

Making the Right Choice for Your Goal

Select and use your holder based on the specific objective of your experiment.

- If your primary focus is accurate corrosion testing: Ensure the holder's conductive material is significantly more noble (less reactive) than your sample, or that the contact point is fully isolated from the testing solution.

- If your primary focus is electrocatalysis: Select a conductive sheet material (e.g., platinum, glassy carbon) that is either completely inert or is intentionally part of the catalytic system you are investigating.

- If your primary focus is routine screening: Prioritize a robust holder design that allows for quick, consistent sample mounting and is easy to clean to ensure high throughput and repeatability.

A clear understanding of this fundamental tool is the first step toward achieving reliable and insightful electrochemical results.

Summary Table:

| Component | Primary Function | Key Features |

|---|---|---|

| Clip Head | Secures the sample and provides electrical contact. | Conductive sheet (Pt, Au, GC, Ti); Firm mechanical grip. |

| Insulating Rod | Acts as a safe handle and electrically isolates the sample. | Made of inert materials (PTFE, PEEK); Chemically resistant. |

| Binding Post | Connects the holder to the electrochemical workstation. | Completes the electrical circuit for measurement and control. |

Ready to achieve precise and reliable electrochemical results? The right electrode holder is critical for the integrity of your data. KINTEK specializes in high-quality lab equipment and consumables, including a range of electrode holders designed for corrosion testing, electrocatalysis, and routine screening. Our experts can help you select the perfect tool for your specific application. Contact our team today to discuss your laboratory needs and ensure your experiments are built on a solid foundation.

Visual Guide

Related Products

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Customizable PTFE Wafer Carriers for Semiconductor and Lab Applications

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

- Button Battery Case for Battery Lab Applications

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

People Also Ask

- How should the PTFE electrode stand and its components be cleaned after use? A Step-by-Step Guide to Prevent Contamination

- How can corrosion of the sample holder be prevented when using corrosive chemicals? Protect Your Lab's Integrity

- What are the recommended and prohibited cleaning methods for the PTFE electrode stand? Protect Your Lab Equipment

- How should a PTFE cleaning basket be stored when not in use? Maximize Lifespan & Prevent Contamination

- Why is high-purity PTFE selected as the sample holder for zirconium alloy corrosion tests? Gain Unmatched Data Accuracy