To properly clean a PTFE electrode stand, you must use gentle methods appropriate for its different materials. The primary method is wiping the surfaces with deionized water or a suitable solvent like alcohol using a soft cloth. It is absolutely prohibited to use sharp or abrasive tools, such as steel wool or metal scrapers, as they will cause permanent scratches and compromise the integrity of the PTFE and glass surfaces.

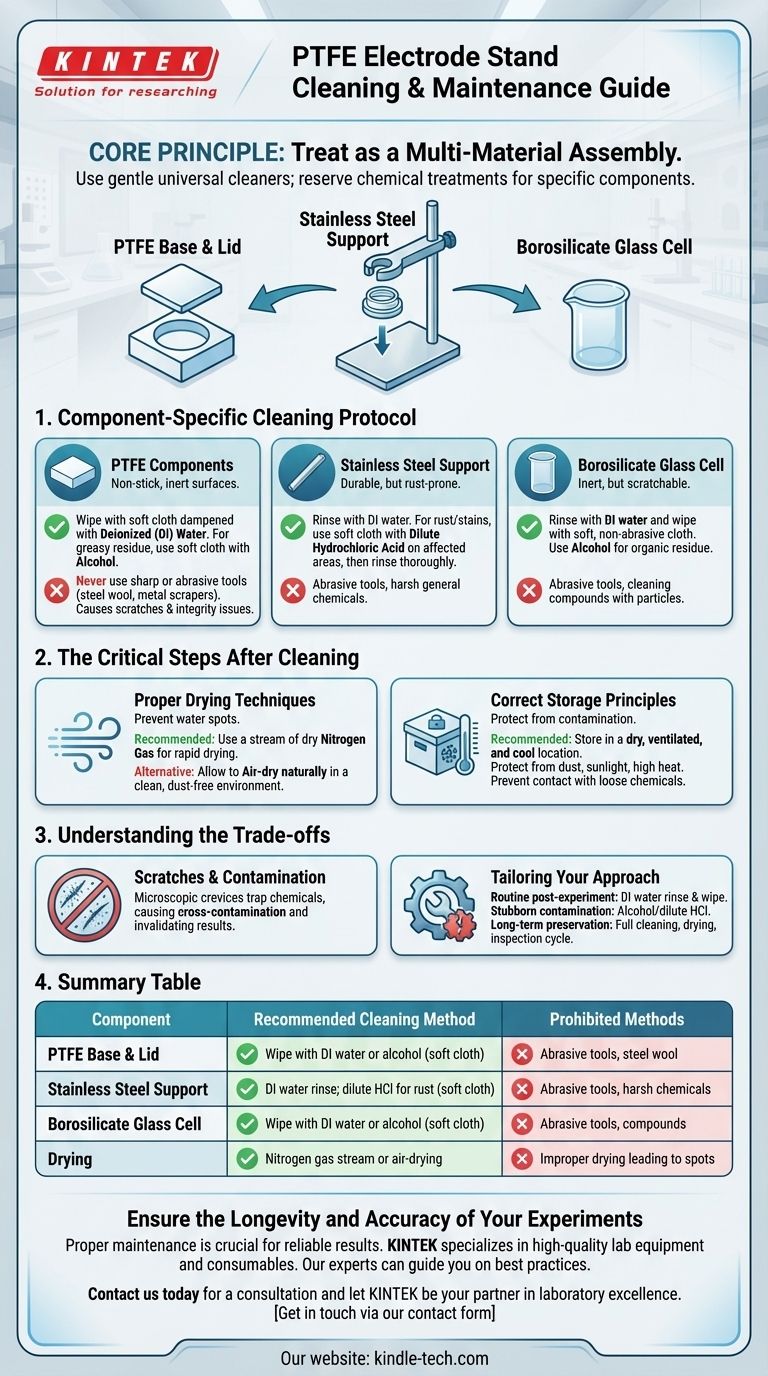

The core principle is to view the electrode stand not as a single object, but as a multi-material assembly. Proper maintenance requires using gentle universal cleaners like deionized water, and reserving specific chemical treatments only for the components that require them, such as the stainless steel support.

A Component-Specific Cleaning Protocol

An electrode stand is a precision assembly, typically composed of PTFE, stainless steel, and borosilicate glass. Each material requires a slightly different approach to ensure its longevity and prevent cross-contamination in your experiments.

Cleaning the PTFE Base and Lid

The non-stick, chemically inert nature of PTFE makes it easy to clean. For routine cleaning, simply rinse and wipe with a soft cloth dampened with deionized (DI) water.

If you encounter greasy residues, a soft cloth with alcohol is effective for removal. The goal is to remove contaminants without physically altering the surface.

Cleaning the Stainless Steel Support

The stainless steel support rod is durable but can be susceptible to certain types of corrosion or rust, especially with exposure to halide-containing electrolytes.

After rinsing with DI water, inspect the steel for any stubborn stains or rust spots. To treat these, use a soft cloth dampened with dilute hydrochloric acid specifically on the affected metal area, then rinse thoroughly with DI water.

Cleaning the Borosilicate Glass Cell

Like PTFE, borosilicate glass is highly inert but can be scratched. Use the same method as for PTFE: rinse with DI water and wipe with a soft, non-abrasive cloth.

For any organic residue, alcohol is a safe and effective solvent. Avoid any cleaning compound that contains abrasive particles.

The Critical Steps After Cleaning

Cleaning is only half the process. Proper drying and storage are essential for preventing future contamination and degradation of the apparatus.

Proper Drying Techniques

After a thorough rinse, components must be completely dried. You can use a stream of dry nitrogen gas for rapid, residue-free drying.

Alternatively, you can allow the components to air-dry naturally in a clean, dust-free environment. This prevents water spots, which can contain impurities.

Correct Storage Principles

Store the clean, dry stand in a dry, ventilated, and cool location. It must be protected from dust, direct sunlight, and high-temperature environments.

Crucially, prevent the stand from coming into physical contact with other loose chemicals during storage, as this could cause an unexpected reaction and damage the materials.

Understanding the Trade-offs: Maintenance vs. Neglect

Failing to adhere to a proper maintenance protocol introduces risks that go beyond simple cosmetic damage.

The Risk of Scratches and Contamination

Scratches on a PTFE or glass surface are not just visual defects. They create microscopic crevices that can trap residual chemicals from a previous experiment.

This trapped material can then leach out during a subsequent procedure, causing cross-contamination and invalidating your results. Using prohibited tools like steel wool creates these exact conditions.

When to Clean vs. When to Repair

During routine maintenance (monthly or more with heavy use), inspect for physical damage. Minor cracks in the PTFE can sometimes be fixed.

After cleaning and roughening the surface, a specialized PTFE repair agent can be used. Deeper cracks or significant deformation, however, may require component replacement.

Pre-Use Inspection is Non-Negotiable

Before every use, perform a quick inspection. Ensure the base is stable, the support mast slides smoothly, and all adjustment knobs are secure.

If a lifting mechanism is stuck, it is likely due to debris. Clean the mechanism and apply a very small amount of appropriate lubricant to ensure smooth operation.

Tailoring Your Approach

Your specific cleaning and maintenance routine should align with your usage patterns and experimental demands.

- If your primary focus is routine post-experiment cleanup: A thorough rinse and wipe with deionized water on all components is sufficient.

- If you are dealing with stubborn contamination: Use alcohol for grease on PTFE/glass and a soft cloth with dilute hydrochloric acid specifically for rust on the stainless steel support.

- If your goal is long-term preservation: Implement a full cycle of cleaning, drying, pre-use inspection, and proper storage to maximize the stand's lifespan and reliability.

By treating your electrode stand as the precision instrument it is, you ensure its reliability and the integrity of your results.

Summary Table:

| Component | Recommended Cleaning Method | Prohibited Methods |

|---|---|---|

| PTFE Base & Lid | Wipe with DI water or alcohol (soft cloth) | Abrasive tools, steel wool |

| Stainless Steel Support | DI water rinse; dilute HCl for rust (soft cloth) | Abrasive tools, harsh chemicals |

| Borosilicate Glass Cell | Wipe with DI water or alcohol (soft cloth) | Abrasive tools, compounds |

| Drying | Nitrogen gas stream or air-drying | Improper drying leading to spots |

Ensure the Longevity and Accuracy of Your Experiments

Proper maintenance of your PTFE electrode stand is crucial for reliable results and equipment longevity. KINTEK specializes in high-quality lab equipment and consumables, serving the precise needs of laboratories.

Our experts can help you select the right cleaning agents and provide guidance on best practices for all your lab equipment.

Contact us today for a consultation and let KINTEK be your partner in laboratory excellence. Get in touch via our contact form

Visual Guide

Related Products

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Customizable PTFE Wafer Carriers for Semiconductor and Lab Applications

- Custom PTFE Teflon Parts Manufacturer for PTFE Measuring Cylinder 10/50/100ml

- Platinum Auxiliary Electrode for Laboratory Use

- Custom PTFE Teflon Parts Manufacturer Adjustable Height Flower Basket

People Also Ask

- Why is it necessary to utilize PTFE sample holders in electroless nickel plating? Ensure Process Integrity

- How should a PTFE cleaning basket be stored when not in use? Maximize Lifespan & Prevent Contamination

- Why is high-purity PTFE selected as the sample holder for zirconium alloy corrosion tests? Gain Unmatched Data Accuracy

- What materials are the sample holders made of? Engineered with PTFE and PEEK for Purity

- What are the storage requirements for the PTFE electrode stand after cleaning? Preserve Purity and Equipment Longevity