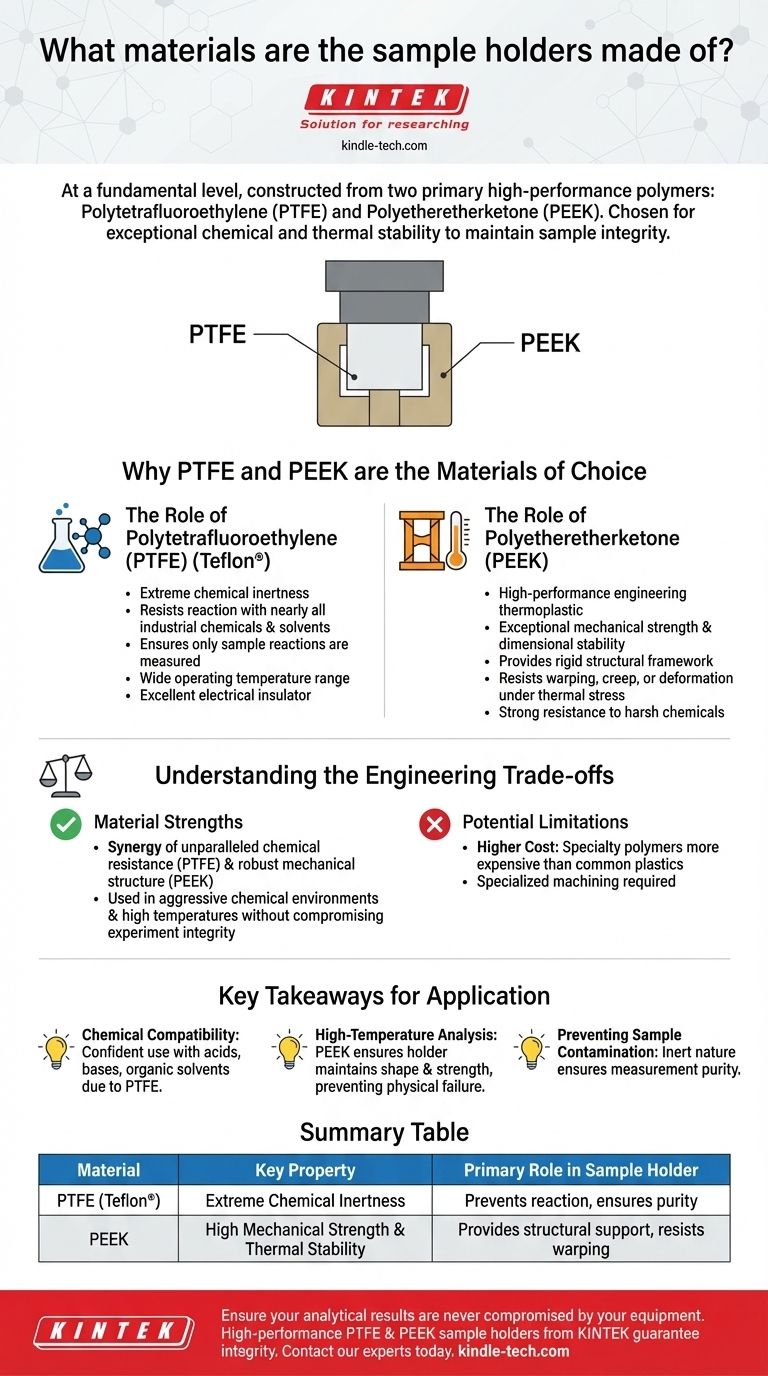

At a fundamental level, the sample holder is constructed from two primary high-performance polymers: Polytetrafluoroethylene (PTFE) and Polyetheretherketone (PEEK). These materials are specifically chosen for their exceptional chemical and thermal stability, which are critical for maintaining sample integrity during analysis.

The choice of PTFE and PEEK is not arbitrary; it's a deliberate engineering decision to ensure the holder remains inert and structurally sound across a wide range of demanding chemical and thermal environments, preventing contamination of the sample.

Why PTFE and PEEK are the Materials of Choice

The function of a sample holder is to secure a specimen for analysis without interfering with the measurement. This requires materials that do not react with the sample, degrade under heat, or introduce impurities. Both PTFE and PEEK excel in these areas.

The Role of Polytetrafluoroethylene (PTFE)

PTFE, commonly known by its trade name Teflon®, is renowned for its extreme chemical inertness. It resists reaction with nearly all industrial chemicals and solvents.

This non-reactivity is the primary reason for its use. It ensures that the only chemical reactions being measured are those from the sample itself, not from the holder.

Additionally, PTFE has a very wide operating temperature range and is an excellent electrical insulator, preventing any unwanted electrical interference during analysis.

The Role of Polyetheretherketone (PEEK)

PEEK is a high-performance engineering thermoplastic valued for its exceptional mechanical strength and dimensional stability, especially at high temperatures.

Where PTFE provides chemical resistance, PEEK provides the rigid structural framework for the sample holder. It does not easily warp, creep, or deform, even under significant thermal stress.

PEEK also exhibits strong resistance to harsh chemicals, though it is slightly less inert than PTFE. The combination of the two materials leverages the best properties of each.

Understanding the Engineering Trade-offs

While PTFE and PEEK are ideal for this application, no material is perfect. Understanding their limitations provides a complete picture of the sample holder's design.

Material Strengths

The core advantage is the synergy between the two polymers. PTFE offers unparalleled chemical resistance, while PEEK provides the robust mechanical structure needed to hold the sample securely.

This combination allows the holder to be used in aggressive chemical environments and at high temperatures without compromising the integrity of the experiment.

Potential Limitations

The primary trade-off is cost. Both PTFE and PEEK are specialty polymers and are significantly more expensive than common plastics like polyethylene or polypropylene.

Machining these materials also requires specialized knowledge and tooling, further contributing to the overall cost of the sample holder. However, for high-stakes scientific or industrial analysis, this cost is justified by the need for reliable and uncontaminated results.

Key Takeaways for Application

The material composition directly impacts how and where you can use the sample holder.

- If your primary focus is chemical compatibility: You can be confident using the holder with a vast range of acids, bases, and organic solvents due to the presence of PTFE.

- If your primary focus is high-temperature analysis: The PEEK component ensures the holder will maintain its shape and strength, preventing physical failure during the experiment.

- If your primary focus is preventing sample contamination: The inert nature of both materials is precisely why they were selected, ensuring measurement purity.

Ultimately, the use of PTFE and PEEK empowers you to trust that your results are a true reflection of your sample, not an artifact of your equipment.

Summary Table:

| Material | Key Property | Primary Role in Sample Holder |

|---|---|---|

| PTFE (Teflon®) | Extreme Chemical Inertness | Prevents reaction with samples, ensures measurement purity |

| PEEK | High Mechanical Strength & Thermal Stability | Provides rigid structural support, resists warping/deformation |

Ensure your analytical results are never compromised by your equipment. The high-performance PTFE and PEEK sample holders from KINTEK are engineered for scientists and lab professionals who demand absolute accuracy. Whether you're working with aggressive chemicals, high temperatures, or sensitive samples, our holders guarantee integrity.

Contact our experts today to find the perfect sample holder for your specific application and experience the KINTEK difference in laboratory reliability.

Visual Guide

Related Products

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Customizable PTFE Wafer Carriers for Semiconductor and Lab Applications

- Customizable XRD Sample Holders for Diverse Research Applications

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Vacuum Cold Mounting Machine for Sample Preparation

People Also Ask

- What are the recommended and prohibited cleaning methods for the PTFE electrode stand? Protect Your Lab Equipment

- Why is it necessary to utilize PTFE sample holders in electroless nickel plating? Ensure Process Integrity

- How should a PTFE cleaning basket be stored when not in use? Maximize Lifespan & Prevent Contamination

- How should the PTFE electrode stand and its components be cleaned after use? A Step-by-Step Guide to Prevent Contamination

- How does a custom PTFE electrode holder contribute to the accuracy of immersion tests? Ensure Precise Steel Analysis