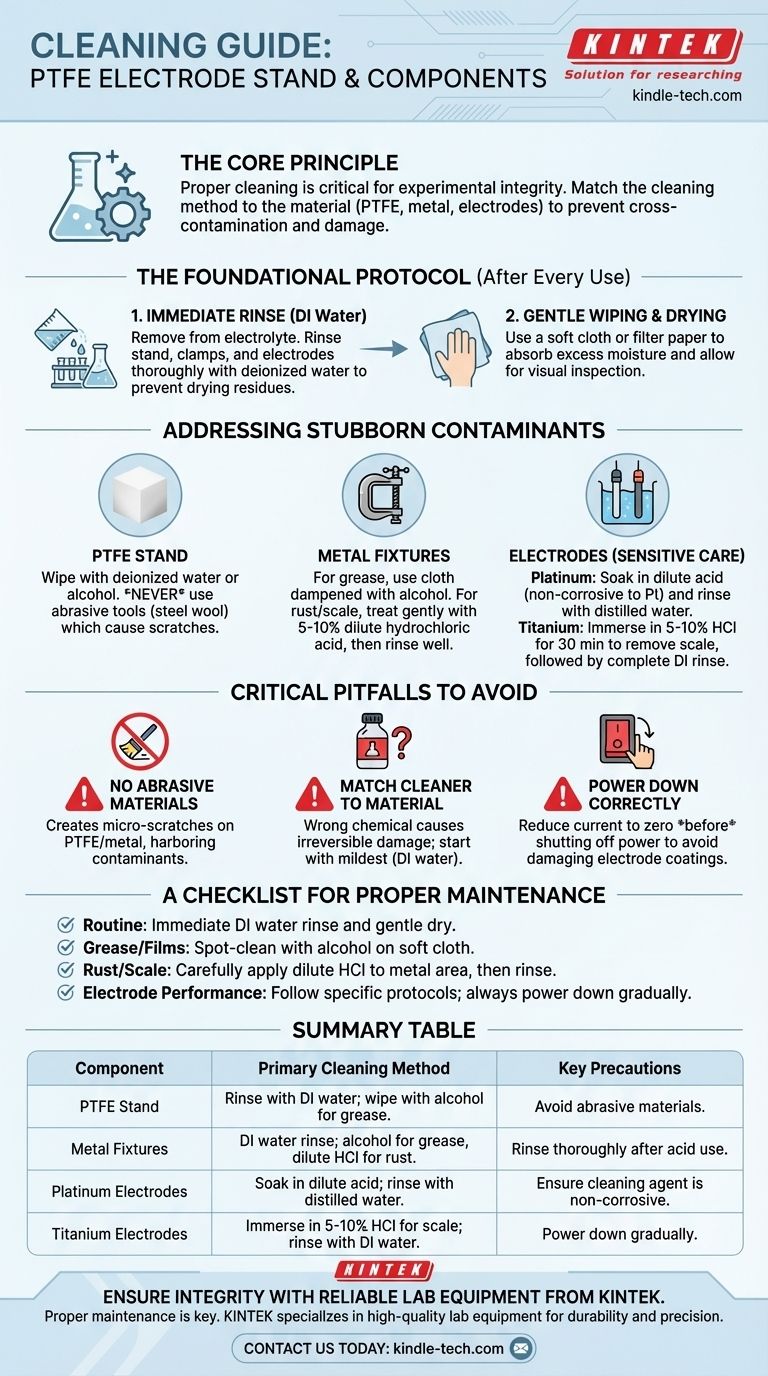

The standard procedure for cleaning a PTFE electrode stand and its components begins with an immediate and thorough rinse using deionized water to remove any residual electrolyte. For more stubborn contaminants, specific treatments are required, such as using a soft cloth dampened with alcohol for grease or dilute hydrochloric acid for metal rust on clamps and fixtures.

Proper cleaning is not merely about aesthetics; it is a critical step in maintaining experimental integrity. The core principle is to match the cleaning method to the specific material—the PTFE body, the metal fixtures, and the electrode itself—to prevent cross-contamination and avoid damaging sensitive components.

The Foundational Cleaning Protocol

This initial procedure should be performed immediately after every use to prevent the crystallization of salts and the corrosion of metal parts.

Step 1: Immediate Rinse with Deionized Water

After an experiment, promptly remove the electrodes and fixtures from the electrolyte. Rinse all components—the PTFE stand, clamps, and electrodes—thoroughly with deionized (DI) or distilled water. This is the single most important step to prevent residues from drying and becoming difficult to remove.

Step 2: Gentle Wiping and Drying

Use a soft cloth or filter paper to gently wipe down the surfaces and absorb excess moisture. This prevents water spots and allows for a clear visual inspection of the equipment.

Addressing Stubborn Contaminants

If a simple water rinse is insufficient, targeted cleaning methods are necessary. Always apply these methods carefully and only to the affected areas.

Cleaning the PTFE Stand

The PTFE body is chemically resistant but physically soft. Clean its surface by wiping with deionized water or a suitable solvent like alcohol. Never use sharp or abrasive tools like steel wool, as they will permanently scratch and damage the surface.

Treating Metal Clamps and Fixtures

For visible grease or oily residues on metal parts, use a soft cloth dampened with alcohol. If you notice rust or stubborn inorganic scale on stainless steel or other metallic fixtures, gently treat the area with a cloth dampened in a 5-10% dilute hydrochloric acid solution, then rinse thoroughly with deionized water.

Special Care for Electrodes

Electrodes are sensitive and expensive components that require specific care.

- Platinum Electrodes: If a platinum electrode has stubborn stains, ensure any cleaning agent used is not corrosive to platinum. Before use, it's often standard practice to clean it by soaking it in a dilute acid solution and rinsing with distilled water.

- Titanium Electrodes: To remove surface scale, you can periodically immerse a titanium electrode in 5-10% dilute hydrochloric acid for about 30 minutes, followed by a complete DI water rinse.

Critical Pitfalls to Avoid

Mistakes during cleaning can be more damaging than the experiment itself. Avoiding these common errors is essential for the longevity of your equipment.

Never Use Abrasive Materials

Abrasive pads, brushes, or powders will create micro-scratches on PTFE and metal surfaces. These scratches can harbor contaminants in future experiments and compromise the integrity of your setup.

Match the Cleaner to the Material

Using the wrong chemical can cause irreversible damage. A strong acid might be fine for removing scale on a titanium electrode but could corrode a different type of metal clamp or fixture. When in doubt, start with the mildest cleaning agent (deionized water).

Power Down Correctly

For active electrodes like coated titanium, always reduce the current to zero before shutting off the power supply. A sudden power cut can cause a reverse potential, which can strip or damage the electrode's catalytic coating.

A Checklist for Proper Maintenance

Follow this guide to ensure your equipment remains in optimal condition, providing reliable and reproducible results.

- For routine, daily use: Immediately rinse all components with deionized water after the experiment, then gently dry and store them properly.

- If you see grease or organic films: Use alcohol on a soft cloth to spot-clean the affected metal or PTFE parts.

- If you find rust or inorganic scale: Carefully apply dilute hydrochloric acid to the specific metal area, then neutralize and rinse thoroughly with deionized water.

- To ensure long-term electrode performance: Follow the specific cleaning and maintenance protocol for your electrode material and always power down gradually.

Properly maintaining your equipment is the foundation of accurate and repeatable scientific work.

Summary Table:

| Component | Primary Cleaning Method | Key Precautions |

|---|---|---|

| PTFE Stand | Rinse with DI water; wipe with alcohol for grease. | Avoid abrasive materials to prevent scratches. |

| Metal Fixtures | DI water rinse; use alcohol for grease or dilute HCl for rust. | Rinse thoroughly with DI water after acid use. |

| Platinum Electrodes | Soak in dilute acid; rinse with distilled water. | Ensure cleaning agent is non-corrosive to platinum. |

| Titanium Electrodes | Immerse in 5-10% HCl for scale; rinse with DI water. | Power down gradually to avoid coating damage. |

Ensure the integrity of your experiments with reliable lab equipment from KINTEK.

Proper maintenance is key to accurate results. KINTEK specializes in high-quality lab equipment and consumables, including electrochemical setups, designed for durability and precision. Our experts can help you select the right tools and provide guidance on best practices for care and maintenance.

Contact us today to discuss your laboratory needs and discover how our solutions can enhance your workflow and data reliability.

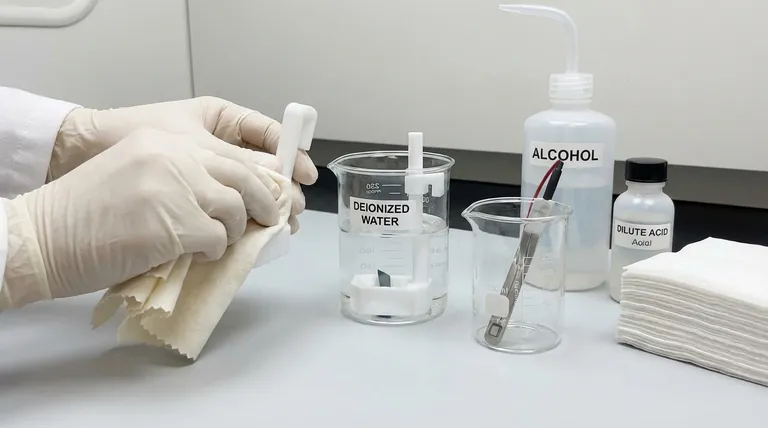

Visual Guide

Related Products

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Custom PTFE Teflon Parts Manufacturer for PTFE Measuring Cylinder 10/50/100ml

- Platinum Auxiliary Electrode for Laboratory Use

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Rotating Platinum Disk Electrode for Electrochemical Applications

People Also Ask

- Why is high-purity PTFE selected as the sample holder for zirconium alloy corrosion tests? Gain Unmatched Data Accuracy

- How does a custom PTFE electrode holder contribute to the accuracy of immersion tests? Ensure Precise Steel Analysis

- How can corrosion of the sample holder be prevented when using corrosive chemicals? Protect Your Lab's Integrity

- How should a PTFE cleaning basket be stored when not in use? Maximize Lifespan & Prevent Contamination

- What materials are the sample holders made of? Engineered with PTFE and PEEK for Purity