Unlike a simple container, a ball mill's capacity is not a single, fixed volume. It is a dynamic measure of performance defined by the rate at which it can process material to a desired particle size. This capacity is influenced by the mill's physical dimensions, the properties of the material being ground, and several critical operating parameters.

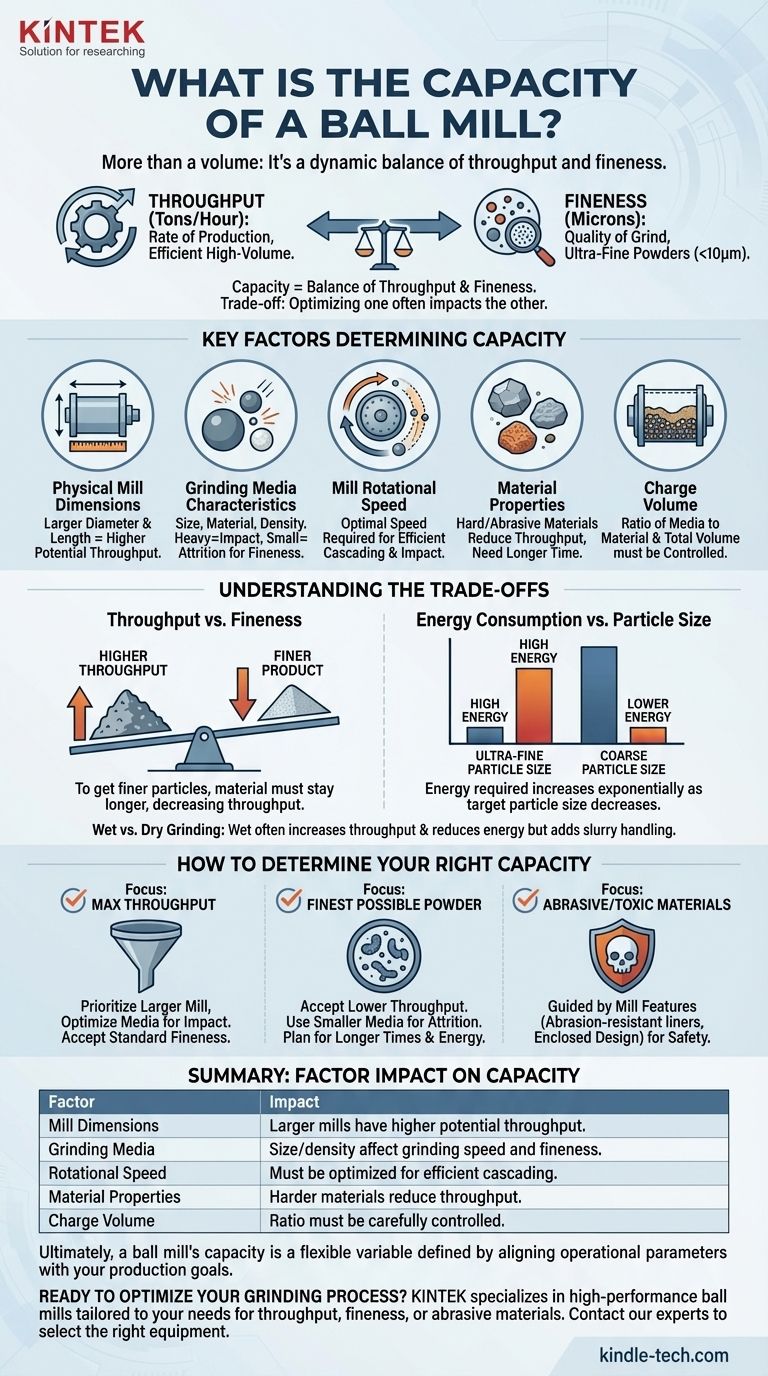

The true capacity of a ball mill is a balance between its throughput (how much material it can process per hour) and the fineness of the final product. Optimizing one of these factors will almost always involve a trade-off with the other.

Defining "Capacity" in a Ball Mill

To understand a ball mill's potential, we must think of capacity in two distinct ways. One is not more important than the other; they are two sides of the same coin that define the mill's performance for a specific job.

Throughput: The Rate of Production

Throughput is the measure of mass processed over time, typically expressed in tons per hour.

This metric is most critical in large-scale industrial operations where the primary goal is to process a high volume of material efficiently.

Fineness: The Quality of the Grind

Fineness refers to the final particle size of the ground material, often measured in microns.

The references note that ball mills excel at producing very fine powders, sometimes less than 10 microns. Achieving this level of fineness is often the primary goal in pharmaceutical or chemical applications.

Key Factors That Determine Capacity

A ball mill's effective capacity is not predetermined. It is the result of a complex interplay between its design, its operation, and the material it is processing.

Physical Mill Dimensions

The physical size of the mill's cylindrical shell—its diameter and length—is the most fundamental factor. A larger mill can hold a greater volume of both grinding media and material, which directly correlates to higher potential throughput.

Grinding Media Characteristics

The grinding media (the balls) do the work. Their size, material (e.g., steel, ceramic), and density are critical.

Heavier, denser media provide more impact force, which can increase grinding speed. However, using smaller media increases the surface area for attrition, which is essential for achieving ultra-fine particle sizes.

Mill Rotational Speed

The speed at which the mill rotates is a crucial operational parameter.

There is an optimal speed for every mill and application. If the speed is too low, the balls will simply roll down the material pile, resulting in inefficient grinding. If it's too high, centrifugal force will pin the balls to the mill's outer wall, preventing the cascading and impact needed for effective size reduction.

Material Properties

The characteristics of the feed material have a massive impact on capacity.

Harder and more abrasive materials require more energy and a longer residence time in the mill, which lowers the overall throughput. The initial size of the feed material also plays a key role; a smaller starting size will require less work to reach the target fineness.

Charge Volume

A ball mill is only ever partially filled. The ratio of grinding media to the material being ground, as well as the total volume they occupy within the mill (the "charge level"), must be carefully controlled to ensure efficient operation.

Understanding the Trade-offs

Achieving the ideal performance from a ball mill requires navigating a series of critical trade-offs. Understanding these compromises is key to successful operation.

Throughput vs. Fineness

This is the most significant trade-off. To achieve a finer final product, the material must remain inside the mill for a longer period. This longer residence time necessarily decreases the overall throughput (tons per hour).

Energy Consumption vs. Particle Size

Grinding is an energy-intensive process. The energy required to reduce particle size increases exponentially as the target size gets smaller. Producing an ultra-fine powder requires significantly more power than producing a merely coarse one.

Wet vs. Dry Grinding

Ball mills are suitable for both wet and dry processes. Wet grinding can often increase throughput and reduce energy consumption, but it introduces the need to handle a slurry and eventually dry the final product, adding process complexity.

How to Determine the Right Capacity for Your Needs

Selecting or operating a ball mill requires a clear understanding of your primary objective. Your goal will dictate which parameters and trade-offs you prioritize.

- If your primary focus is maximum throughput: You should prioritize a larger mill, optimize media for impact, and accept a final particle size that meets but does not drastically exceed your specification.

- If your primary focus is achieving the finest possible powder: You will need to accept a lower throughput, utilize smaller grinding media to maximize attrition, and plan for longer milling times and higher energy costs.

- If your primary focus is processing abrasive or toxic materials: Your decision will be guided by the mill's features, such as abrasion-resistant liners and its enclosed design, which ensures safe handling regardless of its raw throughput.

Ultimately, a ball mill's capacity is a flexible variable that you define by aligning its operational parameters with your specific production goals.

Summary Table:

| Factor | Impact on Capacity |

|---|---|

| Mill Dimensions | Larger mills have higher potential throughput. |

| Grinding Media | Size and density affect grinding speed and fineness. |

| Rotational Speed | Must be optimized for efficient cascading and impact. |

| Material Properties | Harder, abrasive materials reduce throughput. |

| Charge Volume | Ratio of media to material must be carefully controlled. |

Ready to optimize your grinding process? KINTEK specializes in high-performance ball mills and lab equipment tailored to your specific needs—whether your priority is high throughput, ultra-fine particle size, or handling abrasive materials. Our experts will help you select the right equipment to balance efficiency and quality. Contact us today for a consultation and let us enhance your laboratory's capabilities!

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the primary function of a Planetary Ball Mill in the synthesis of Na3SbS4-xSex? Achieve Peak Ionic Conductivity

- What are the technical advantages of tungsten carbide grinding jars? Ensure 99.95%+ Purity in Ceramic Milling

- What is the ratio for ball milling? Find the Optimal Ball-to-Powder Ratio for Your Lab

- What is the role of a vertical planetary ball mill in Cu-18Ni-2W pretreatment? Achieve Superior Alloy Homogeneity

- What role does a high-energy ball mill play in the synthesis of halide solid electrolytes like Li3YCl6 and Li3InCl6?

- How does high-energy ball milling equipment contribute to the age hardening of aluminum alloys? Boost Alloy Strength

- How does a planetary ball mill prepare silver and diamond composites? Achieve Perfect Homogeneity and Density Balance

- What is the function of a high-energy ball mill in the preparation of nanoparticle-reinforced steel? | KINTEK