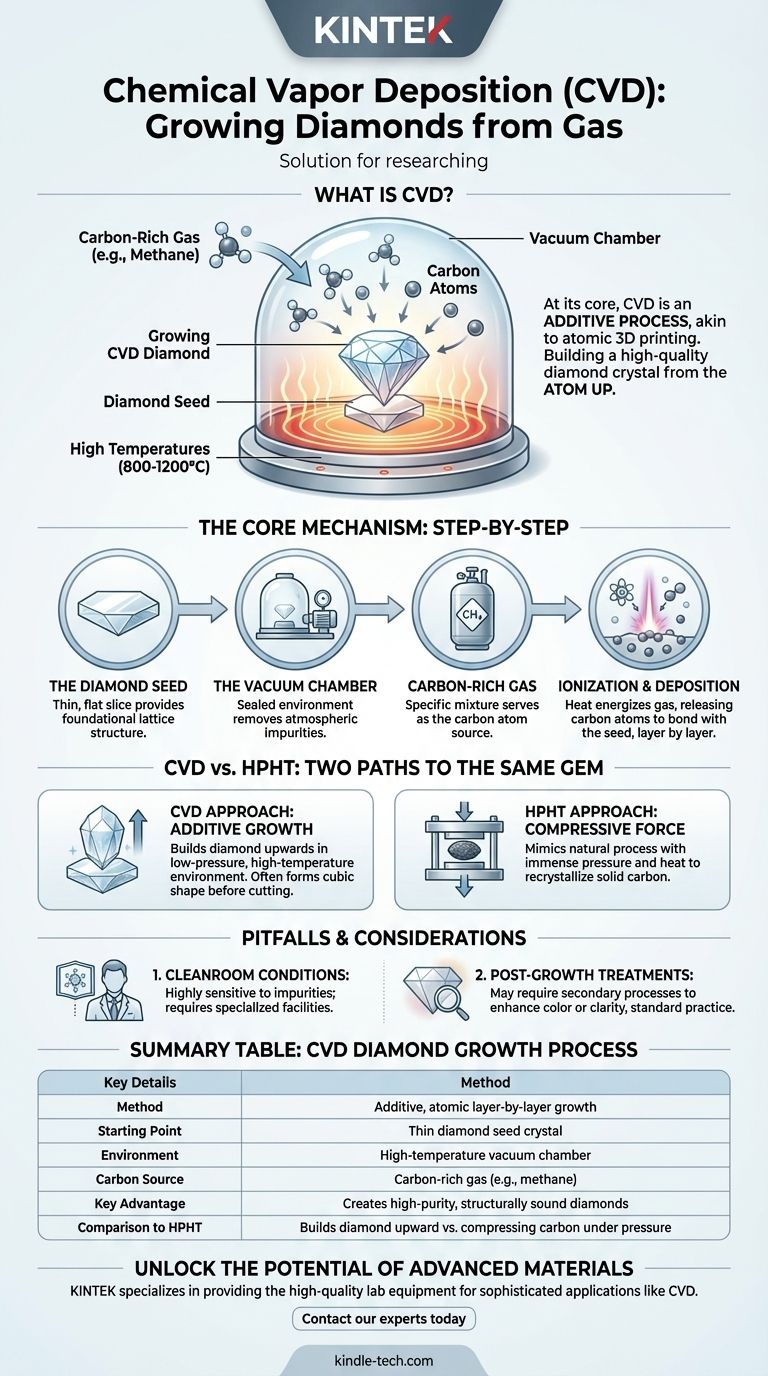

At its core, Chemical Vapor Deposition (CVD) is a method for growing a diamond from a gas. Inside a vacuum chamber, a small diamond "seed" is exposed to a carbon-rich gas at very high temperatures. This process causes carbon atoms to break away from the gas and deposit onto the seed, building up the diamond layer by layer over several weeks.

The CVD method is fundamentally an additive process, akin to atomic 3D printing. It builds a high-quality diamond crystal from the atom up, rather than by replicating the immense pressure found deep within the earth.

The Core Mechanism of CVD Diamond Growth

To understand CVD, it's best to break the process down into its essential stages. Each step is precisely controlled within highly specialized equipment to ensure the final product is a structurally sound and pure diamond.

The Starting Point: The Diamond Seed

The entire process begins with a very thin, flat slice of a pre-existing diamond, known as a diamond seed. This seed provides the foundational crystal lattice structure upon which the new diamond will grow.

Creating the Ideal Environment: The Vacuum Chamber

This diamond seed is placed inside a sealed vacuum chamber. The chamber is critical for removing any other atmospheric gases that could introduce impurities or interfere with the crystal growth.

The Key Ingredient: Carbon-Rich Gas

Once sealed, the chamber is filled with a specific mixture of gases, primarily one that is rich in carbon, such as methane. This gas serves as the source for the carbon atoms that will form the new diamond.

The Growth Phase: Ionization and Deposition

The chamber is then heated to extremely high temperatures. This intense heat energizes the gas, breaking the molecules apart and releasing individual carbon atoms. These freed atoms then settle, or deposit, onto the surface of the diamond seed, bonding with its crystal structure and replicating it perfectly. This layer-by-layer accumulation is what "grows" the diamond.

CVD vs. HPHT: Two Paths to the Same Gem

CVD is one of two primary methods for creating lab-grown diamonds. The other is High-Pressure/High-Temperature (HPHT). Understanding their differences clarifies what makes the CVD process unique.

The CVD Approach: Additive Growth

As described, CVD is an additive process. It builds the diamond upwards from a flat seed in a low-pressure, high-temperature environment. The final diamond often grows in a somewhat cubic shape before it is cut.

The HPHT Approach: Compressive Force

The HPHT method more closely mimics the natural process inside the Earth's mantle. It takes a source of pure carbon, places it in a large mechanical press, and subjects it to immense pressure and heat. This combination of forces compels the carbon to break down and recrystallize into a diamond.

Common Pitfalls and Considerations

While a highly advanced technique, the CVD process requires immense precision. Any deviation can impact the quality of the final gemstone.

The Need for Cleanroom Conditions

The process is highly sensitive to impurities. CVD diamond growth must occur in cleanroom facilities using sophisticated equipment. Even minuscule contaminants in the gas or chamber can disrupt the crystal lattice, causing imperfections.

Post-Growth Treatments

Sometimes, diamonds produced via the CVD method may require secondary treatments to enhance their color or clarity. This is a standard part of the production process for many lab-grown gems and does not compromise the final stone's integrity.

Making the Right Choice for Your Goal

Understanding the technical differences between growth methods allows you to appreciate the unique characteristics of each type of diamond.

- If your primary focus is the growth process: Remember that CVD "builds" a diamond atom by atom from a gas, while HPHT "compresses" solid carbon into a crystal.

- If your primary focus is the technology: Recognize that CVD is a state-of-the-art material science process that demands extreme control over temperature, pressure, and chemical purity.

- If your primary focus is the final stone: Both methods produce real diamonds that are chemically and physically identical to their natural counterparts; the difference lies entirely in their origin story.

Ultimately, appreciating the CVD process is to see a lab-grown diamond not as a replica, but as a marvel of controlled chemical engineering.

Summary Table:

| CVD Diamond Growth Process | Key Details |

|---|---|

| Method | Additive, atomic layer-by-layer growth |

| Starting Point | Thin diamond seed crystal |

| Environment | High-temperature vacuum chamber |

| Carbon Source | Carbon-rich gas (e.g., methane) |

| Key Advantage | Creates high-purity, structurally sound diamonds |

| Comparison to HPHT | Builds diamond upward vs. compressing carbon under pressure |

Unlock the potential of advanced materials in your lab. The precise control of the CVD process is a testament to modern material science. KINTEK specializes in providing the high-quality lab equipment and consumables needed for such sophisticated applications. Whether you are researching diamond growth or other advanced material synthesis, our expertise ensures you have the reliable tools for success. Contact our experts today to discuss how we can support your laboratory's specific needs.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit